Slab cutting involves slicing large, continuous pieces of stone, ideal for countertops and expansive surfaces, while tile cutting is designed for smaller, modular pieces used in flooring and backsplashes. Slab cutting requires precision tools to maintain the integrity and thickness of the stone, whereas tile cutting emphasizes creating uniform, smaller shapes with smooth edges. Both techniques demand specialized equipment, but the choice depends on the project's size, pattern, and installation complexity.

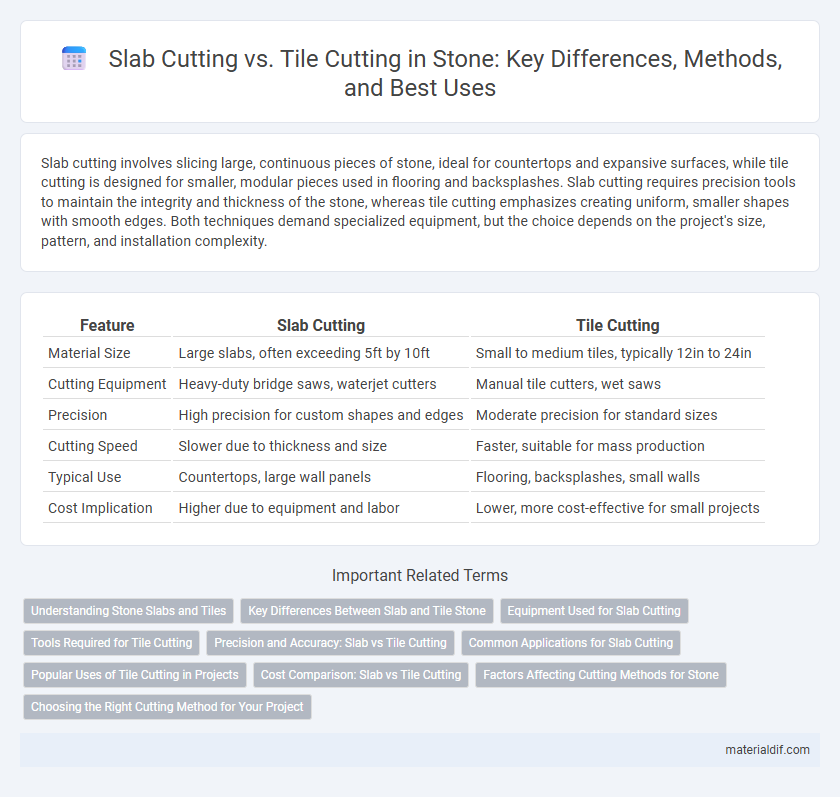

Table of Comparison

| Feature | Slab Cutting | Tile Cutting |

|---|---|---|

| Material Size | Large slabs, often exceeding 5ft by 10ft | Small to medium tiles, typically 12in to 24in |

| Cutting Equipment | Heavy-duty bridge saws, waterjet cutters | Manual tile cutters, wet saws |

| Precision | High precision for custom shapes and edges | Moderate precision for standard sizes |

| Cutting Speed | Slower due to thickness and size | Faster, suitable for mass production |

| Typical Use | Countertops, large wall panels | Flooring, backsplashes, small walls |

| Cost Implication | Higher due to equipment and labor | Lower, more cost-effective for small projects |

Understanding Stone Slabs and Tiles

Stone slabs are large, continuous pieces typically quarried in widths of 4 to 6 feet and thicknesses ranging from 2 to 3 centimeters, offering a seamless appearance ideal for countertops and wall cladding. Tile cutting involves smaller, pre-cut sections of stone often measuring 12x12 inches or less, commonly used in flooring and backsplashes where modularity and pattern variety are key. Understanding the differences in size, thickness, and intended application helps optimize fabrication techniques and material efficiency for slabs versus tiles.

Key Differences Between Slab and Tile Stone

Slab cutting involves slicing large, thick pieces of natural stone like granite or marble, typically used for countertops and large surfaces, offering fewer seams and a more continuous appearance. Tile cutting focuses on smaller, thinner stone pieces ideal for flooring or wall applications, allowing for versatile designs and easier installation in tight spaces. The key differences lie in size, thickness, and application, influencing durability, cost, and aesthetic impact.

Equipment Used for Slab Cutting

Slab cutting requires specialized equipment such as bridge saws and wire saws designed to handle large, heavy stone slabs with precision and minimal waste. These machines use diamond-tipped blades and high-powered motors to ensure smooth, accurate cuts through dense materials like granite, marble, and quartz. The advanced technology in slab cutting equipment allows for efficient resizing and shaping, which is essential for custom countertops and large-scale stone installations.

Tools Required for Tile Cutting

Tile cutting requires specialized tools such as wet saws with diamond blades, tile nippers, and scoring tools to ensure precise and clean cuts on ceramic, porcelain, or glass tiles. Wet saws use water to cool the blade and reduce dust, making them ideal for straight cuts and intricate patterns, while tile nippers are suitable for small, detailed adjustments. Scoring tools provide a manual option for snapping tiles along straight lines, preferred for thinner or softer tile materials.

Precision and Accuracy: Slab vs Tile Cutting

Slab cutting offers higher precision and accuracy due to the use of advanced equipment that handles large, continuous stone surfaces, minimizing errors and maintaining uniform thickness. Tile cutting, meanwhile, involves smaller, individual pieces where slight deviations can occur more frequently due to manual handling and smaller-scale tools. The consistency in slab cutting ensures seamless installations and better alignment in large projects, crucial for achieving a polished, professional finish.

Common Applications for Slab Cutting

Slab cutting is primarily used for large-scale applications such as countertops, kitchen islands, and bathroom vanities where precision and seamless surfaces are essential. Thicker and larger stone slabs accommodate heavy-duty uses in commercial kitchens, facades, and flooring. This method supports custom shaping and finishing, making it ideal for architectural elements and bespoke interior designs.

Popular Uses of Tile Cutting in Projects

Tile cutting is widely utilized in residential and commercial flooring projects due to its precision in shaping ceramic, porcelain, and natural stone tiles into custom sizes and patterns. It enables the creation of intricate designs, border details, and seamless fits around fixtures, enhancing both aesthetic appeal and functionality. Popular applications include kitchen backsplashes, bathroom walls, and decorative mosaic installations where uniformity and clean edges are crucial.

Cost Comparison: Slab vs Tile Cutting

Slab cutting generally incurs higher upfront costs due to the size and weight of stone slabs requiring specialized equipment and labor, while tile cutting is more cost-effective for smaller, standardized pieces. The price per square foot for slab cutting can be significantly greater than tile cutting, reflecting the complexity and time involved in handling large slabs. However, slab cutting may offer long-term savings through reduced seams and installation time compared to multiple tile pieces.

Factors Affecting Cutting Methods for Stone

Factors affecting stone cutting methods include stone hardness, thickness, and intended application. Slab cutting requires precision and powerful tools like diamond wire saws for large, thick stone, ensuring smooth, even surfaces ideal for countertops. Tile cutting suits smaller, thinner stone pieces, relying on wet saws or handheld tools to achieve detailed shapes without damaging the material.

Choosing the Right Cutting Method for Your Project

Selecting the appropriate cutting method depends on the material type, project scale, and precision requirements. Slab cutting offers efficiency and accuracy for large stone surfaces like countertops and flooring, while tile cutting provides versatility for smaller, intricate designs and mosaic patterns. Proper evaluation ensures optimal results, minimizing waste and enhancing the quality of stone installations.

Slab Cutting vs Tile Cutting Infographic

materialdif.com

materialdif.com