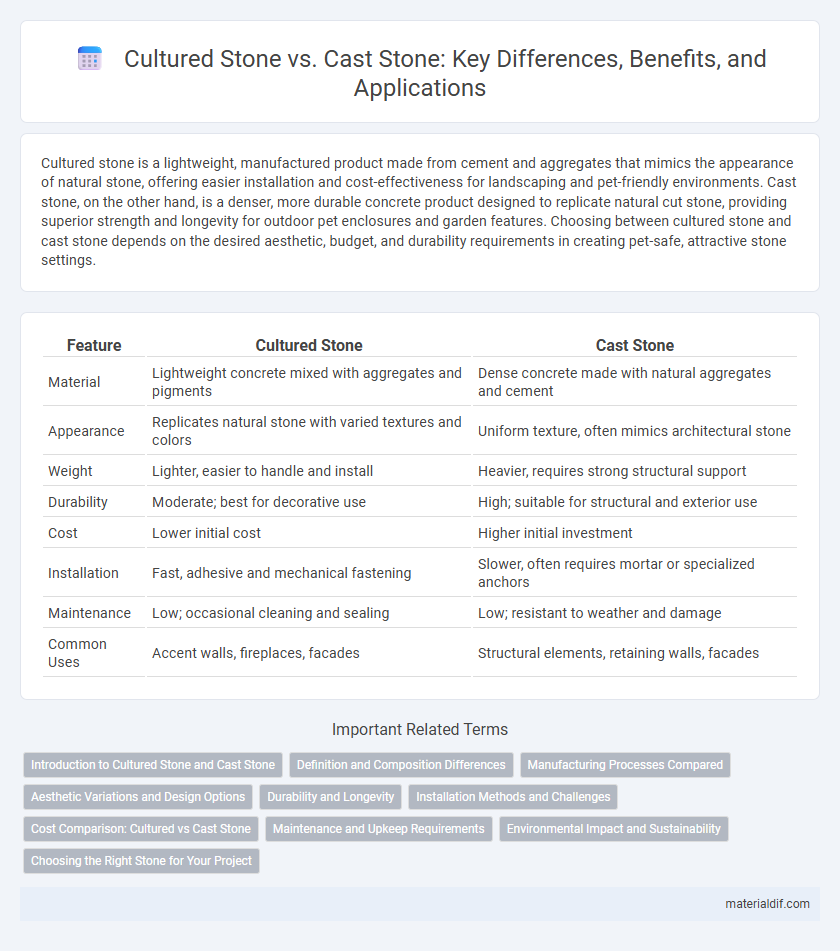

Cultured stone is a lightweight, manufactured product made from cement and aggregates that mimics the appearance of natural stone, offering easier installation and cost-effectiveness for landscaping and pet-friendly environments. Cast stone, on the other hand, is a denser, more durable concrete product designed to replicate natural cut stone, providing superior strength and longevity for outdoor pet enclosures and garden features. Choosing between cultured stone and cast stone depends on the desired aesthetic, budget, and durability requirements in creating pet-safe, attractive stone settings.

Table of Comparison

| Feature | Cultured Stone | Cast Stone |

|---|---|---|

| Material | Lightweight concrete mixed with aggregates and pigments | Dense concrete made with natural aggregates and cement |

| Appearance | Replicates natural stone with varied textures and colors | Uniform texture, often mimics architectural stone |

| Weight | Lighter, easier to handle and install | Heavier, requires strong structural support |

| Durability | Moderate; best for decorative use | High; suitable for structural and exterior use |

| Cost | Lower initial cost | Higher initial investment |

| Installation | Fast, adhesive and mechanical fastening | Slower, often requires mortar or specialized anchors |

| Maintenance | Low; occasional cleaning and sealing | Low; resistant to weather and damage |

| Common Uses | Accent walls, fireplaces, facades | Structural elements, retaining walls, facades |

Introduction to Cultured Stone and Cast Stone

Cultured stone is a manufactured product designed to replicate the appearance and texture of natural stone while offering lighter weight and easier installation. Cast stone is a concrete-based material molded to mimic natural stone, known for its durability and architectural versatility. Both materials serve as cost-effective alternatives to natural stone in construction and decorative applications.

Definition and Composition Differences

Cultured stone is a lightweight, manufactured product made from a blend of cement, aggregates, and iron oxides designed to mimic natural stone's texture and appearance. Cast stone, on the other hand, is a highly durable architectural precast concrete material composed primarily of fine and coarse aggregates, cement, and chemical admixtures to replicate natural cut stone. The key difference lies in their composition: cultured stone emphasizes aesthetic appeal with lighter weight and easier installation, while cast stone focuses on strength and structural performance.

Manufacturing Processes Compared

Cultured stone is manufactured by mixing cement, aggregates, and iron oxides poured into molds to replicate natural stone textures, allowing for lightweight and versatile designs. Cast stone involves a mixture of refined aggregates, Portland cement, water, and pigments, which is cast into detailed molds and cured to achieve a denser, more durable product resembling natural limestone or sandstone. The precision and curing methods of cast stone result in higher strength, while cultured stone emphasizes cost-effectiveness and ease of installation.

Aesthetic Variations and Design Options

Cultured stone offers a wide range of realistic textures and color variations, closely mimicking natural stone, making it ideal for diverse aesthetic applications in residential and commercial projects. Cast stone provides a more uniform appearance with precise shapes and smooth finishes, often preferred for architectural elements such as columns, window surrounds, and decorative facades. Both materials enhance design flexibility but cater to different stylistic preferences and functional requirements within construction and landscaping.

Durability and Longevity

Cultured stone is made from lightweight concrete and resins, offering moderate durability with resistance to cracking but may fade over time under harsh weather conditions. Cast stone, composed of high-strength concrete and aggregates, provides superior longevity and can withstand extreme environmental stress, making it ideal for structural and decorative purposes. Both materials require maintenance, but cast stone's denser composition ensures greater durability and a longer lifespan in exterior applications.

Installation Methods and Challenges

Cultured stone installation involves lightweight panels that are easier to handle and typically affixed using mortar or adhesive on surfaces like wood or masonry, reducing labor time and minimizing structural reinforcement. Cast stone requires casting in molds and demands skilled labor for precise placement, curing, and weight support, often necessitating additional structural reinforcement due to its density. The main challenges with cultured stone include ensuring proper sealing to prevent moisture infiltration, while cast stone presents challenges with handling heavy blocks and longer curing periods before installation completion.

Cost Comparison: Cultured vs Cast Stone

Cultured stone typically costs between $6 and $12 per square foot, making it a more budget-friendly option compared to cast stone, which ranges from $15 to $30 per square foot. The lower price of cultured stone reflects its lightweight, manufactured composition, while cast stone's higher cost is due to its durability and resemblance to natural limestone or concrete. Cost considerations should include installation expenses, as cultured stone is easier to handle and install, reducing labor fees.

Maintenance and Upkeep Requirements

Cultured stone requires minimal maintenance due to its lightweight, non-porous composition, resisting moisture and staining better than cast stone. Cast stone, made from a mixture of cement and aggregates, demands regular sealing and cleaning to prevent weathering and mildew buildup. Both materials benefit from periodic inspections, but cultured stone generally offers lower upkeep costs and easier long-term preservation.

Environmental Impact and Sustainability

Cultured stone is made from lightweight concrete infused with natural stone aggregates, reducing quarry depletion and minimizing environmental disruption compared to traditional stone extraction. Cast stone, composed primarily of Portland cement, sand, and crushed stone, has a higher carbon footprint due to cement manufacturing emissions but offers durability and longevity that can offset initial impacts over its lifecycle. Choosing either material involves weighing the trade-off between sustainable resource use in cultured stone and the durable, low-maintenance properties of cast stone for long-term sustainability.

Choosing the Right Stone for Your Project

Choosing between cultured stone and cast stone depends on factors like durability, appearance, and budget. Cultured stone, made from lightweight concrete and aggregates, offers versatile aesthetics and easier installation, ideal for decorative applications. Cast stone provides greater strength and weather resistance, making it suitable for structural projects requiring authentic stone characteristics.

Cultured Stone vs Cast Stone Infographic

materialdif.com

materialdif.com