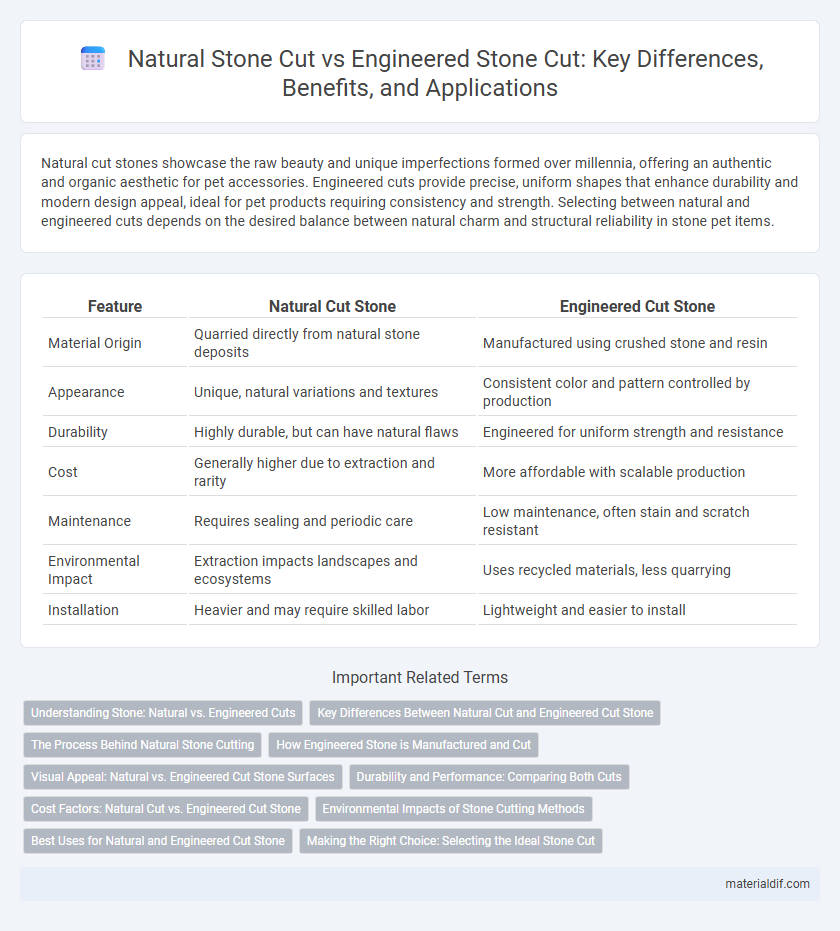

Natural cut stones showcase the raw beauty and unique imperfections formed over millennia, offering an authentic and organic aesthetic for pet accessories. Engineered cuts provide precise, uniform shapes that enhance durability and modern design appeal, ideal for pet products requiring consistency and strength. Selecting between natural and engineered cuts depends on the desired balance between natural charm and structural reliability in stone pet items.

Table of Comparison

| Feature | Natural Cut Stone | Engineered Cut Stone |

|---|---|---|

| Material Origin | Quarried directly from natural stone deposits | Manufactured using crushed stone and resin |

| Appearance | Unique, natural variations and textures | Consistent color and pattern controlled by production |

| Durability | Highly durable, but can have natural flaws | Engineered for uniform strength and resistance |

| Cost | Generally higher due to extraction and rarity | More affordable with scalable production |

| Maintenance | Requires sealing and periodic care | Low maintenance, often stain and scratch resistant |

| Environmental Impact | Extraction impacts landscapes and ecosystems | Uses recycled materials, less quarrying |

| Installation | Heavier and may require skilled labor | Lightweight and easier to install |

Understanding Stone: Natural vs. Engineered Cuts

Natural stone cuts preserve the original texture and mineral composition, resulting in unique patterns and increased durability ideal for countertops and flooring. Engineered cuts combine natural stone fragments with resins and pigments to offer consistent color, enhanced strength, and reduced porosity, making them suitable for high-traffic areas. Choosing between natural and engineered stone depends on aesthetic preferences, maintenance requirements, and intended application.

Key Differences Between Natural Cut and Engineered Cut Stone

Natural cut stone is extracted directly from quarries, preserving its original texture, color, and unique veining, which results in one-of-a-kind pieces ideal for authentic designs. Engineered cut stone is manufactured by combining natural stone fragments with resins and pigments, offering greater uniformity, enhanced durability, and customizable shapes suitable for modern construction needs. The key differences lie in the natural variability and aesthetic uniqueness of natural cut stone versus the controlled consistency and strength of engineered cut stone.

The Process Behind Natural Stone Cutting

Natural stone cutting involves extracting slabs directly from quarries using diamond wire saws or channeling machines, preserving the stone's inherent texture and mineral composition. The process requires skilled craftsmanship to shape and polish the stone while maintaining its structural integrity and natural appearance. Unlike engineered cuts, natural cutting emphasizes minimal alteration, showcasing authentic patterns and unique veining intrinsic to each stone block.

How Engineered Stone is Manufactured and Cut

Engineered stone is manufactured by combining crushed natural quartz with resin and pigments, then compressing the mixture under high pressure to create a durable, non-porous surface. Advanced cutting tools like CNC machines and diamond-tipped saws precisely shape engineered stone slabs with minimal waste and high accuracy. This process allows for consistent thickness and customizable designs, distinguishing engineered stone from natural cut stone.

Visual Appeal: Natural vs. Engineered Cut Stone Surfaces

Natural cut stone surfaces display unique, irregular textures and color variations that enhance their organic visual appeal, making each piece distinctly one-of-a-kind. Engineered cut stone provides consistent patterns and smooth finishes, offering a uniform and polished look ideal for modern design aesthetics. Variations in veining and surface detail in natural cuts create a dynamic visual interest, whereas engineered cuts emphasize precision and repeatability in appearance.

Durability and Performance: Comparing Both Cuts

Natural cut stones exhibit superior durability due to their inherent geological formation, resisting wear and environmental stress more effectively than engineered cuts. Engineered cut stones offer consistent performance with precise dimensions and enhanced structural integrity, ideal for uniform applications. Both cuts provide distinct advantages: natural cuts excel in longevity and authenticity, while engineered cuts deliver optimized strength and design flexibility.

Cost Factors: Natural Cut vs. Engineered Cut Stone

Natural cut stone generally incurs higher costs due to extraction, transportation, and minimal processing, preserving its unique, organic appearance. Engineered cut stone offers cost savings through controlled manufacturing processes, consistent sizing, and reduced material wastage, making it a budget-friendly option for large-scale projects. Labor expenses also differ, with natural stone requiring skilled artisans for finishing, while engineered stone can be installed more efficiently, further influencing overall project budgets.

Environmental Impacts of Stone Cutting Methods

Natural cut stone involves minimal processing, resulting in lower energy consumption and reduced carbon emissions compared to engineered cut stone, which requires intensive machinery and chemical treatments. Engineered stone often generates hazardous waste and silica dust, posing significant environmental health risks during production. Selecting natural cut stone supports sustainability by preserving raw materials and minimizing pollution in quarrying and fabrication processes.

Best Uses for Natural and Engineered Cut Stone

Natural cut stone, known for its unique textures and organic imperfections, is best suited for outdoor landscapes, facades, and rustic architectural designs where authenticity and durability against weather are priorities. Engineered cut stone, offering consistent shapes and sizes with enhanced strength, excels in indoor applications such as countertops, flooring, and decorative walls where precision and uniformity enhance aesthetic appeal. Choosing between natural and engineered stone depends on project requirements for appearance, structural integrity, and environmental exposure.

Making the Right Choice: Selecting the Ideal Stone Cut

Natural cuts showcase the stone's authentic texture, color variations, and organic patterns, offering uniqueness in every piece. Engineered cuts provide precision, uniformity, and enhanced durability, ideal for structured architectural designs and consistent surfaces. Selecting the ideal stone cut depends on balancing aesthetic preference, application requirements, and maintenance considerations to achieve lasting beauty and functionality.

Natural Cut vs Engineered Cut Infographic

materialdif.com

materialdif.com