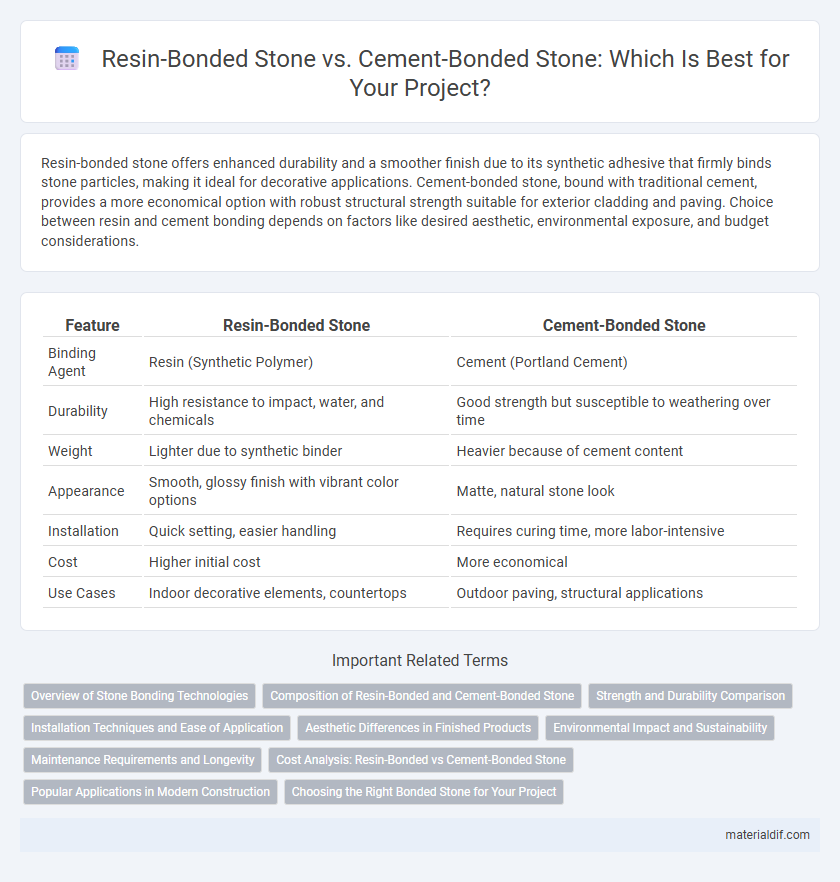

Resin-bonded stone offers enhanced durability and a smoother finish due to its synthetic adhesive that firmly binds stone particles, making it ideal for decorative applications. Cement-bonded stone, bound with traditional cement, provides a more economical option with robust structural strength suitable for exterior cladding and paving. Choice between resin and cement bonding depends on factors like desired aesthetic, environmental exposure, and budget considerations.

Table of Comparison

| Feature | Resin-Bonded Stone | Cement-Bonded Stone |

|---|---|---|

| Binding Agent | Resin (Synthetic Polymer) | Cement (Portland Cement) |

| Durability | High resistance to impact, water, and chemicals | Good strength but susceptible to weathering over time |

| Weight | Lighter due to synthetic binder | Heavier because of cement content |

| Appearance | Smooth, glossy finish with vibrant color options | Matte, natural stone look |

| Installation | Quick setting, easier handling | Requires curing time, more labor-intensive |

| Cost | Higher initial cost | More economical |

| Use Cases | Indoor decorative elements, countertops | Outdoor paving, structural applications |

Overview of Stone Bonding Technologies

Resin-bonded stone uses synthetic resin adhesives to create a durable, water-resistant bond ideal for decorative applications and intricate installations. Cement-bonded stone employs cementitious materials to provide strong, load-bearing connections, commonly used in construction and structural projects. Both technologies enhance stone's versatility, with resin bonding favored for precision and aesthetics, while cement bonding excels in strength and cost-effectiveness.

Composition of Resin-Bonded and Cement-Bonded Stone

Resin-bonded stone consists primarily of natural aggregates mixed with a polyester or epoxy resin binder, creating a strong, water-resistant, and lightweight composite ideal for decorative applications. Cement-bonded stone combines crushed stone aggregates with Portland cement and water, resulting in a denser, heavier, and more porous material suited for structural uses. The distinct resin and cement binders directly influence the stones' durability, adhesion properties, and suitability for specific environments.

Strength and Durability Comparison

Resin-bonded stone exhibits superior strength and durability due to the strong adhesion properties of synthetic resins, which create a robust, flexible bond resistant to cracking and weathering. In contrast, cement-bonded stone relies on traditional cement paste that tends to be more brittle and less resistant to moisture penetration, leading to a shorter lifespan under harsh environmental conditions. This makes resin-bonded stone more suitable for structures requiring enhanced mechanical performance and long-term resilience.

Installation Techniques and Ease of Application

Resin-bonded stone offers a faster installation process due to its lightweight and adhesive-backed design, enabling direct application without mixing or curing. Cement-bonded stone requires surface preparation, mixing of cement, and curing time, making the installation more labor-intensive and time-consuming. The ease of application of resin-bonded stone makes it ideal for DIY projects and quick renovations, while cement-bonded stone suits long-term durability in structural settings.

Aesthetic Differences in Finished Products

Resin-bonded stone exhibits a glossy and vibrant finish due to the clear polymer resin that enhances the natural color and texture of the stone, resulting in a sleek and modern aesthetic. Cement-bonded stone tends to have a matte, muted surface with a more rugged and natural look, as the cement overlay can slightly dull the stone's original hues. The choice between resin-bonded and cement-bonded stone significantly impacts the visual appeal, with resin providing a polished elegance and cement offering a rustic, understated charm.

Environmental Impact and Sustainability

Resin-bonded stone typically has a lower environmental impact than cement-bonded stone due to its reduced energy consumption during production and the use of synthetic resins that limit natural resource extraction. Cement-bonded stone involves higher carbon emissions owing to the cement manufacturing process, which contributes significantly to global CO2 levels. Sustainable construction projects increasingly prefer resin-bonded stone for its durability, recyclability, and lower overall carbon footprint.

Maintenance Requirements and Longevity

Resin-bonded stone surfaces exhibit superior resistance to water absorption and chemical stains, resulting in lower maintenance requirements compared to cement-bonded stone, which often demands regular sealing and cleaning to prevent deterioration. Resin bonding enhances durability by providing a flexible yet strong adhesion, extending the lifespan of stone installations beyond the typical 20-30 years associated with cement-bonded alternatives. The improved adhesion and impermeability of resin-bonded stone contribute to its longer service life, making it ideal for high-traffic or moisture-prone environments.

Cost Analysis: Resin-Bonded vs Cement-Bonded Stone

Resin-bonded stone typically incurs higher upfront costs due to the price of synthetic adhesives and specialized labor required for application, while cement-bonded stone leverages more affordable, traditional cement mixtures and standard installation techniques, resulting in lower initial expenses. Over time, resin-bonded stone may offer cost savings through enhanced durability and resistance to environmental factors, reducing maintenance and replacement frequency compared to cement-bonded stone. Budget considerations must weigh the immediate financial outlay against long-term performance and upkeep costs to determine the most economical choice for specific construction projects.

Popular Applications in Modern Construction

Resin-bonded stone offers exceptional adhesion and waterproofing, making it popular for exterior cladding, countertops, and decorative facades in modern construction. Cement-bonded stone is favored for structural elements like paving, retaining walls, and load-bearing surfaces due to its durability and cost-effectiveness. Both materials are integral in sustainable building designs, combining aesthetic appeal with functional strength.

Choosing the Right Bonded Stone for Your Project

Resin-bonded stone offers superior durability and water resistance, making it ideal for high-traffic areas and outdoor applications, while cement-bonded stone provides greater fire resistance and cost-effectiveness for interior uses. Selecting the right bonded stone depends on environmental exposure, project budget, and desired aesthetic effects. Evaluating factors such as strength, bonding agent properties, and maintenance requirements ensures optimal performance and longevity.

Resin-Bonded Stone vs Cement-Bonded Stone Infographic

materialdif.com

materialdif.com