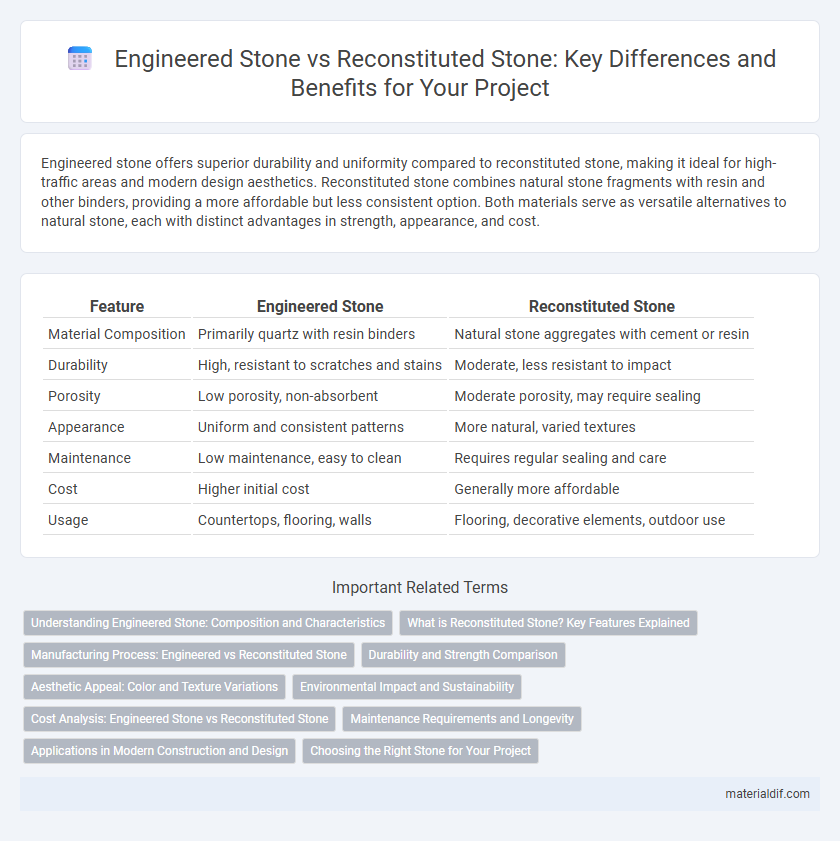

Engineered stone offers superior durability and uniformity compared to reconstituted stone, making it ideal for high-traffic areas and modern design aesthetics. Reconstituted stone combines natural stone fragments with resin and other binders, providing a more affordable but less consistent option. Both materials serve as versatile alternatives to natural stone, each with distinct advantages in strength, appearance, and cost.

Table of Comparison

| Feature | Engineered Stone | Reconstituted Stone |

|---|---|---|

| Material Composition | Primarily quartz with resin binders | Natural stone aggregates with cement or resin |

| Durability | High, resistant to scratches and stains | Moderate, less resistant to impact |

| Porosity | Low porosity, non-absorbent | Moderate porosity, may require sealing |

| Appearance | Uniform and consistent patterns | More natural, varied textures |

| Maintenance | Low maintenance, easy to clean | Requires regular sealing and care |

| Cost | Higher initial cost | Generally more affordable |

| Usage | Countertops, flooring, walls | Flooring, decorative elements, outdoor use |

Understanding Engineered Stone: Composition and Characteristics

Engineered stone is composed of approximately 90-95% crushed natural quartz combined with resin binders and pigments, resulting in a durable and non-porous surface ideal for countertops and flooring. Its manufacturing process ensures consistent color patterns and enhanced resistance to stains, scratches, and heat compared to natural stone. This engineered composition allows for customization in design while maintaining superior strength and low maintenance requirements.

What is Reconstituted Stone? Key Features Explained

Reconstituted stone, also known as engineered stone, is a composite material made from crushed natural stone mixed with resins and pigments for enhanced durability and aesthetic flexibility. Key features include high resistance to stains, scratches, and heat, making it ideal for countertops and flooring applications. The material offers consistent patterns and colors, allowing for customizable designs while maintaining the appearance of natural stone.

Manufacturing Process: Engineered vs Reconstituted Stone

Engineered stone is manufactured by blending crushed natural quartz with resin and pigments, followed by a high-pressure compaction process that creates a dense, non-porous surface. Reconstituted stone involves crushing natural stone fragments, mixing them with binders and adhesives, then molding and curing the mixture to form slabs that resemble natural stone. The key difference lies in engineered stone's use of synthetic resin for durability and uniformity, whereas reconstituted stone relies more on natural stone fragments bonded with cementitious or resin binders.

Durability and Strength Comparison

Engineered stone exhibits superior durability and strength due to its composition of natural quartz combined with resin binders, making it highly resistant to scratches, stains, and impact compared to reconstituted stone, which often includes crushed natural stone and cement that can be more porous and prone to cracking. The high quartz content in engineered stone contributes to its consistent structural integrity, while reconstituted stone's variable mix may lead to uneven strength and increased susceptibility to wear over time. Both materials offer durable options for surfaces, but engineered stone's enhanced hardness and density typically provide longer-lasting performance in high-traffic environments.

Aesthetic Appeal: Color and Texture Variations

Engineered stone offers consistent color and uniform texture achieved through precise manufacturing processes, making it ideal for modern, sleek designs. Reconstituted stone provides greater diversity in color and texture variations, mimicking natural stone patterns for a more authentic and rustic appearance. The choice between engineered and reconstituted stone depends on the desired balance between uniformity and natural aesthetic richness.

Environmental Impact and Sustainability

Engineered stone, composed primarily of quartz and resins, often involves higher energy consumption and the use of non-biodegradable polymers, raising concerns about its environmental footprint compared to reconstituted stone, which typically incorporates recycled natural stone fragments and eco-friendly adhesives. Reconstituted stone demonstrates increased sustainability through the effective reuse of by-products and reduced quarrying activities, minimizing habitat disruption and lowering carbon emissions. Selecting reconstituted stone can contribute to circular economy principles by extending the lifecycle of natural materials and decreasing landfill waste.

Cost Analysis: Engineered Stone vs Reconstituted Stone

Engineered stone typically incurs higher initial costs ranging from $50 to $100 per square foot due to advanced manufacturing processes and durable resin binds, whereas reconstituted stone costs between $30 and $60 per square foot, reflecting its use of crushed natural stone bonded with cement or resin. Maintenance expenses for engineered stone remain low because of its non-porous surface, reducing sealing and repair costs compared to reconstituted stone, which may require regular sealing and is more susceptible to staining. Long-term cost efficiency favors engineered stone for high-traffic applications due to its superior durability and resistance to wear, making it a more cost-effective investment despite the higher upfront price.

Maintenance Requirements and Longevity

Engineered stone, composed of crushed quartz bound with resin, offers enhanced durability and requires minimal maintenance, resisting stains and scratches better than reconstituted stone. Reconstituted stone, produced by blending natural stone fragments with cement or resin, may be more porous and prone to wear, necessitating regular sealing and careful upkeep to maintain its appearance. Longevity of engineered stone typically surpasses reconstituted stone due to its superior resistance to chipping, fading, and bacterial growth, making it ideal for high-traffic areas.

Applications in Modern Construction and Design

Engineered stone, composed primarily of natural quartz and resin, offers superior durability and uniformity, making it ideal for kitchen countertops, flooring, and wall cladding in modern construction. Reconstituted stone, created from crushed natural stone bonded with cement or resin, provides cost-effective versatility suited to exterior facades, landscaping elements, and decorative architectural features. Both materials enhance design flexibility, with engineered stone excelling in high-traffic indoor environments and reconstituted stone favored for customizable shapes and textures in contemporary architectural projects.

Choosing the Right Stone for Your Project

Engineered stone is a high-performance composite made from crushed natural quartz combined with resin, offering superior durability, stain resistance, and uniformity ideal for kitchen countertops and high-traffic surfaces. Reconstituted stone, created by blending natural stone aggregates with cement-based binders, provides a more affordable, customizable option with varied textures and colors suitable for decorative applications and outdoor projects. Selecting the right stone depends on factors like project budget, desired aesthetic, durability requirements, and maintenance considerations to ensure long-lasting performance and appearance.

Engineered Stone vs Reconstituted Stone Infographic

materialdif.com

materialdif.com