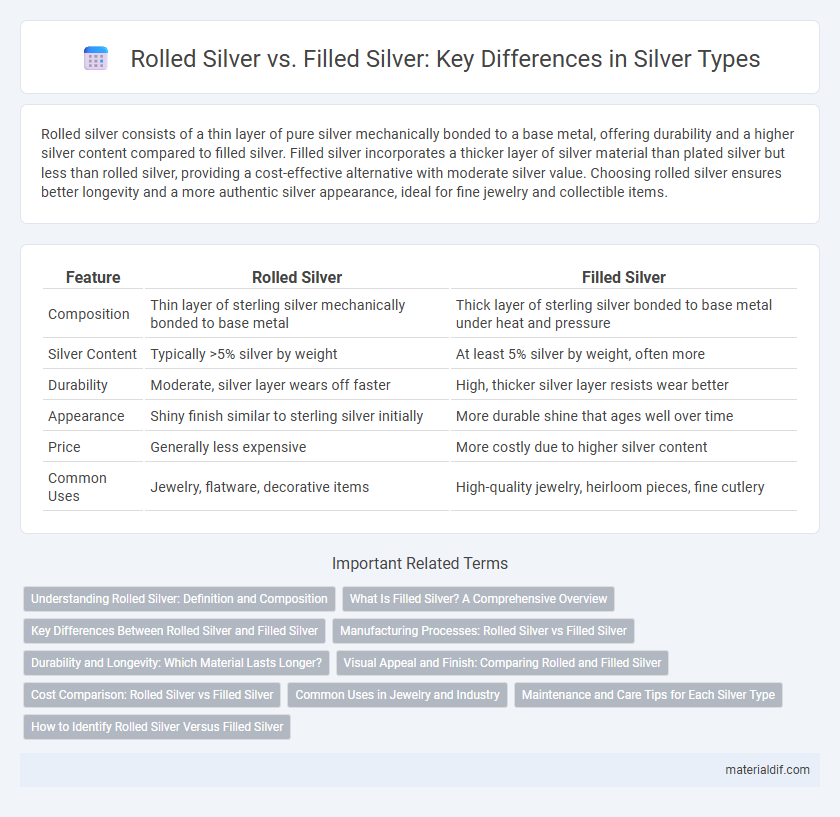

Rolled silver consists of a thin layer of pure silver mechanically bonded to a base metal, offering durability and a higher silver content compared to filled silver. Filled silver incorporates a thicker layer of silver material than plated silver but less than rolled silver, providing a cost-effective alternative with moderate silver value. Choosing rolled silver ensures better longevity and a more authentic silver appearance, ideal for fine jewelry and collectible items.

Table of Comparison

| Feature | Rolled Silver | Filled Silver |

|---|---|---|

| Composition | Thin layer of sterling silver mechanically bonded to base metal | Thick layer of sterling silver bonded to base metal under heat and pressure |

| Silver Content | Typically >5% silver by weight | At least 5% silver by weight, often more |

| Durability | Moderate, silver layer wears off faster | High, thicker silver layer resists wear better |

| Appearance | Shiny finish similar to sterling silver initially | More durable shine that ages well over time |

| Price | Generally less expensive | More costly due to higher silver content |

| Common Uses | Jewelry, flatware, decorative items | High-quality jewelry, heirloom pieces, fine cutlery |

Understanding Rolled Silver: Definition and Composition

Rolled silver, also known as rolled silver plate, is a material made by fusing a thin layer of pure silver or sterling silver onto a core of base metal, typically copper, through a mechanical rolling process. This process creates a durable surface with the appearance and qualities of solid silver while significantly reducing the cost compared to pure silver items. Understanding the composition of rolled silver is crucial for distinguishing it from filled silver, which involves bonding much thicker layers of silver to a core, resulting in different durability and value characteristics.

What Is Filled Silver? A Comprehensive Overview

Filled silver consists of a thick layer of pure or sterling silver mechanically bonded to a base metal core, offering greater durability and affordability compared to solid silver. Unlike rolled silver, which features a thinner bonding process, filled silver contains a significantly heavier silver layer, typically comprising at least 5% of the item's total weight. This composition provides enhanced resistance to tarnish and wear, making filled silver ideal for jewelry and flatware requiring longevity and a luxurious silver appearance.

Key Differences Between Rolled Silver and Filled Silver

Rolled silver is created by fusing a thin layer of pure silver onto a base metal through heat and pressure, resulting in a durable and heavier piece with a higher silver content, typically around 10-25%. Filled silver, or silver filled, involves mechanically bonding a thicker layer of silver to a base metal, offering greater thickness and longevity compared to rolled silver, often marked with a higher silver quality such as 925 sterling. The key differences lie in the silver layer's thickness and manufacturing process, affecting durability, value, and the piece's authenticity in silver jewelry and flatware.

Manufacturing Processes: Rolled Silver vs Filled Silver

Rolled silver is created by compressing silver sheets under heavy rollers to achieve uniform thickness and smoothness, enhancing its durability and consistent surface finish. Filled silver involves bonding a thick layer of sterling silver to a base metal core through heat and pressure, resulting in a composite material that combines the appearance of silver with cost-effective strength. Both manufacturing processes influence the silver item's quality, weight, and resistance to tarnish, with rolled silver offering homogeneity and filled silver providing economical silver coverage.

Durability and Longevity: Which Material Lasts Longer?

Rolled silver, composed of a thick layer of sterling silver fused to a base metal, offers superior durability and longevity compared to filled silver due to its dense silver content. Filled silver contains a thinner layer of silver bonded to a core metal, making it more prone to wear and tarnishing over time. Jewelry crafted from rolled silver maintains its appearance and structural integrity longer, making it a preferred choice for pieces intended for frequent use.

Visual Appeal and Finish: Comparing Rolled and Filled Silver

Rolled silver exhibits a smooth, uniform surface with a bright, lustrous finish due to its solid silver layer mechanically bonded to a base metal, enhancing its visual appeal. Filled silver, composed of a thicker layer of silver mechanically bonded to a core, offers a similar polished look but is generally less brilliant and may show wear more quickly over time. Both options provide attractive finishes, but rolled silver tends to maintain its shine and resistance to tarnish better, making it a preferred choice for high-quality jewelry.

Cost Comparison: Rolled Silver vs Filled Silver

Rolled silver typically costs more than filled silver due to its higher purity and manufacturing process, which involves bonding a thick layer of silver to a base metal. Filled silver offers a more affordable option with a thinner silver layer, making it less expensive but also less durable over time. Consumers seeking long-lasting value often prefer rolled silver despite its higher initial cost, as filled silver may require more frequent replacement or repair.

Common Uses in Jewelry and Industry

Rolled silver is commonly used in jewelry for its durable silver layer bonded to a base metal, offering an affordable alternative to solid silver with high-quality appearance. Filled silver is frequently utilized in both jewelry and industrial applications where thicker silver content is required, such as electronic components and decorative items, due to its enhanced durability and resistance to tarnish. Both materials serve as cost-effective substitutes for solid silver, balancing aesthetics and functional performance in diverse uses.

Maintenance and Care Tips for Each Silver Type

Rolled silver requires gentle cleaning with a soft cloth and mild soap to preserve its thin layer of silver bonded to a base metal, avoiding abrasive materials that can wear down the surface. Filled silver, containing a thicker layer of silver fused to a base metal, can withstand more frequent polishing using a silver polishing cloth to maintain its luster without damaging the underlying metal. Both types benefit from proper storage in anti-tarnish bags or cloths and should be kept away from harsh chemicals, excessive moisture, and prolonged sunlight exposure to prevent tarnish and discoloration.

How to Identify Rolled Silver Versus Filled Silver

Rolled silver, also known as rolled plate, consists of a thick layer of sterling silver mechanically bonded over a base metal, while filled silver features a thinner layer of silver fused to a core metal under heat and pressure. Identifying rolled silver involves measuring the thickness of the silver layer, which is typically much heavier and thicker compared to filled silver, often stamped with marks like ".925" or "RGP" (Rolled Gold Plate) for accuracy. Testing methods such as acid tests or electronic silver testers can differentiate the purity and thickness, while visual inspection of edges or worn areas reveals the base metal in filled silver quicker due to its thinner silver layer.

Rolled Silver vs Filled Silver Infographic

materialdif.com

materialdif.com