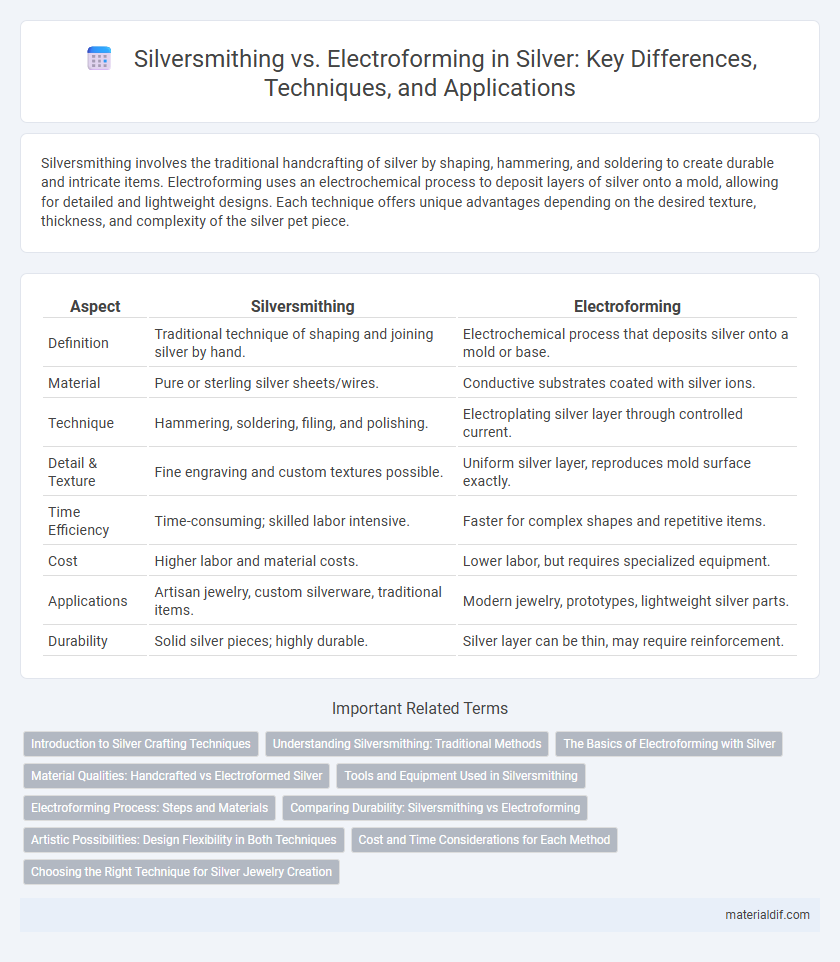

Silversmithing involves the traditional handcrafting of silver by shaping, hammering, and soldering to create durable and intricate items. Electroforming uses an electrochemical process to deposit layers of silver onto a mold, allowing for detailed and lightweight designs. Each technique offers unique advantages depending on the desired texture, thickness, and complexity of the silver pet piece.

Table of Comparison

| Aspect | Silversmithing | Electroforming |

|---|---|---|

| Definition | Traditional technique of shaping and joining silver by hand. | Electrochemical process that deposits silver onto a mold or base. |

| Material | Pure or sterling silver sheets/wires. | Conductive substrates coated with silver ions. |

| Technique | Hammering, soldering, filing, and polishing. | Electroplating silver layer through controlled current. |

| Detail & Texture | Fine engraving and custom textures possible. | Uniform silver layer, reproduces mold surface exactly. |

| Time Efficiency | Time-consuming; skilled labor intensive. | Faster for complex shapes and repetitive items. |

| Cost | Higher labor and material costs. | Lower labor, but requires specialized equipment. |

| Applications | Artisan jewelry, custom silverware, traditional items. | Modern jewelry, prototypes, lightweight silver parts. |

| Durability | Solid silver pieces; highly durable. | Silver layer can be thin, may require reinforcement. |

Introduction to Silver Crafting Techniques

Silversmithing is a traditional silver crafting technique that involves shaping and joining silver through methods like hammering, soldering, and engraving, emphasizing manual skill and precision. Electroforming is a modern technique that uses an electric current to deposit silver onto a mold, allowing for intricate, lightweight designs impossible to achieve by hand. Both methods play essential roles in silver artistry, with silversmithing focusing on craftsmanship and electroforming on innovative structural possibilities.

Understanding Silversmithing: Traditional Methods

Silversmithing involves shaping and joining silver using traditional techniques such as hammering, soldering, and annealing to create detailed and durable jewelry or objects. This hands-on craftsmanship relies on skilled manipulation of solid silver, preserving the metal's natural properties and allowing for intricate designs and textures. Unlike electroforming, which builds layers of metal through electrochemical deposition, silversmithing emphasizes direct manual work with the material for authentic, high-quality silver pieces.

The Basics of Electroforming with Silver

Electroforming with silver involves depositing a thin layer of pure silver onto a conductive substrate through an electrolytic bath, allowing for highly detailed and lightweight metal creations. Unlike traditional silversmithing, which relies on hammering, soldering, and casting, electroforming builds up metal organically from a solution, enabling intricate designs with precision and minimal waste. This technique is ideal for artists and jewelers seeking delicate silver pieces with complex structures that would be difficult to achieve through conventional methods.

Material Qualities: Handcrafted vs Electroformed Silver

Handcrafted silver in silversmithing exhibits unique texture, weight, and durability due to meticulous shaping and hammering of solid silver sheets or wire. Electroformed silver, created through an electrochemical process depositing silver onto a mold, results in lighter, hollow pieces with consistent thickness but less structural strength. The intrinsic material qualities of handcrafted silver offer greater resilience and a distinct artisanal finish compared to the uniform yet delicate nature of electroformed silver items.

Tools and Equipment Used in Silversmithing

Silversmithing relies heavily on traditional hand tools such as hammers, anvils, rolling mills, and soldering equipment to shape and join silver manually, allowing for intricate craftsmanship and detailed designs. In contrast, electroforming primarily uses electrical power supplies, conductive solutions, and precise molds to deposit metal layers through electrochemical processes, requiring less manual shaping but specialized equipment. The hands-on manipulation and variety of classic tools in silversmithing provide greater control over texture and form compared to the technologically driven setup in electroforming.

Electroforming Process: Steps and Materials

Electroforming involves depositing pure silver onto a conductive substrate by submerging the model in an electrolytic bath containing a silver salt solution, typically silver nitrate. The process begins with preparing a conductive base, followed by immersion in the electroforming solution where an electric current reduces silver ions onto the surface, layer by layer, creating a precise and lightweight silver coating. Key materials include the silver electrolyte solution, a power source, conductive substrates for plating, and often a protective resist to define the deposition areas.

Comparing Durability: Silversmithing vs Electroforming

Silversmithing produces solid silver pieces with superior durability and resistance to wear, ideal for heirloom-quality items. Electroforming deposits a thin layer of silver onto a base metal, resulting in lighter but more fragile objects prone to bending or chipping. For long-lasting strength and robustness, silversmithing remains the preferred technique over electroforming.

Artistic Possibilities: Design Flexibility in Both Techniques

Silversmithing offers unparalleled design flexibility through traditional handcrafting, allowing artists to shape, engrave, and texture silver with precision and intricate detail. Electroforming enables the creation of complex, lightweight structures by building up metal layers on virtually any form, expanding artistic possibilities beyond the limitations of solid silver. Both techniques provide unique opportunities for innovative silver art, with silversmithing excelling in classic craftsmanship and electroforming pioneering experimental, organic shapes.

Cost and Time Considerations for Each Method

Silversmithing involves traditional handcrafting techniques that can be time-intensive and costly due to skilled labor and material wastage. Electroforming offers a more efficient process by depositing silver onto a mold, significantly reducing production time and minimizing material use, leading to lower overall costs. Choosing between silversmithing and electroforming depends on project complexity, budget constraints, and desired production volume.

Choosing the Right Technique for Silver Jewelry Creation

Silversmithing involves traditional handcrafting techniques like hammering, soldering, and shaping to create unique, durable silver jewelry pieces with intricate details. Electroforming uses an electrochemical process to deposit silver onto a mold or base, allowing for lightweight designs and complex shapes that may be difficult to achieve by hand. Selecting the right technique depends on factors such as desired texture, weight, production scale, and design complexity in silver jewelry creation.

Silversmithing vs Electroforming Infographic

materialdif.com

materialdif.com