Rolled silver consists of a thick layer of pure silver mechanically bonded to a base metal, offering durability and genuine silver content. Electroplated silver, on the other hand, features a much thinner silver coating deposited through an electrochemical process, which can wear away more quickly over time. Choosing rolled silver ensures longer-lasting quality and a more substantial silver presence compared to electroplated alternatives.

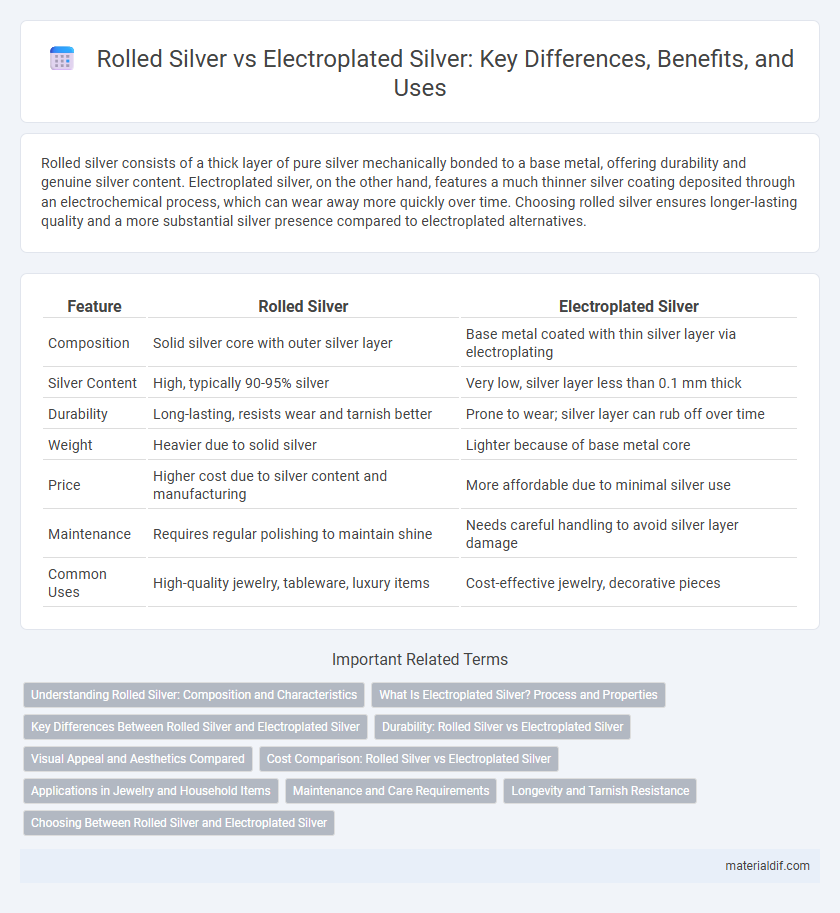

Table of Comparison

| Feature | Rolled Silver | Electroplated Silver |

|---|---|---|

| Composition | Solid silver core with outer silver layer | Base metal coated with thin silver layer via electroplating |

| Silver Content | High, typically 90-95% silver | Very low, silver layer less than 0.1 mm thick |

| Durability | Long-lasting, resists wear and tarnish better | Prone to wear; silver layer can rub off over time |

| Weight | Heavier due to solid silver | Lighter because of base metal core |

| Price | Higher cost due to silver content and manufacturing | More affordable due to minimal silver use |

| Maintenance | Requires regular polishing to maintain shine | Needs careful handling to avoid silver layer damage |

| Common Uses | High-quality jewelry, tableware, luxury items | Cost-effective jewelry, decorative pieces |

Understanding Rolled Silver: Composition and Characteristics

Rolled silver consists of a thick layer of pure silver mechanically bonded to a base metal, typically copper, resulting in higher quality and durability compared to electroplated silver. Its composition usually contains at least 90% silver, offering better resistance to wear and tarnish, making it ideal for fine cutlery and jewelry. The distinct physical properties of rolled silver ensure longevity and maintain the aesthetic appeal without frequent replating or damage.

What Is Electroplated Silver? Process and Properties

Electroplated silver is created by depositing a thin layer of silver onto a base metal, such as copper or brass, using an electrochemical process. This method provides the appearance of solid silver with reduced cost, although the thin silver layer can wear off over time, exposing the underlying metal. The electroplating process enhances surface durability and corrosion resistance but lacks the density and weight of rolled silver, which consists of a thicker silver layer mechanically bonded to a base metal.

Key Differences Between Rolled Silver and Electroplated Silver

Rolled silver is made by fusing a thick layer of pure silver onto a base metal, resulting in a durable product with a higher silver content, typically around 80-90%. Electroplated silver, by contrast, involves depositing a very thin layer of silver onto a base metal through an electrochemical process, offering a less expensive finish but less durability and lower silver content. The key differences lie in thickness, silver purity, lifespan, and overall quality, with rolled silver providing better wear resistance and a more substantial silver presence than electroplated items.

Durability: Rolled Silver vs Electroplated Silver

Rolled silver is created by mechanically bonding a thick layer of pure silver to a base metal, resulting in greater durability and resistance to wear compared to electroplated silver, which has a much thinner silver coating applied through an electrochemical process. The thicker silver layer in rolled silver allows it to withstand frequent use and polishing without exposing the base metal, whereas electroplated silver is prone to chipping and tarnishing over time due to its minimal silver content. For items requiring long-lasting silver appearance and structural integrity, rolled silver offers superior durability compared to electroplated silver.

Visual Appeal and Aesthetics Compared

Rolled silver offers a thicker layer of pure silver, resulting in a richer, more consistent shine and a naturally lustrous appearance that deepens with age. Electroplated silver features a thinner silver coating over a base metal, which can appear less vibrant and wear away faster, revealing the underlying material. The superior durability of rolled silver maintains its visual appeal longer, making it favored for jewelry and decorative items where enduring aesthetics are crucial.

Cost Comparison: Rolled Silver vs Electroplated Silver

Rolled silver typically costs more than electroplated silver due to its higher percentage of pure silver content, usually ranging between 92.5% and 99.9% in sterling or fine silver forms, while electroplated silver consists of a thin layer of silver over a base metal, significantly reducing material expenses. The manufacturing process for rolled silver involves thicker silver sheets, increasing production costs compared to the electroplating technique, which applies a minimal amount of silver via an electrical current. Buyers often pay a premium for rolled silver's durability and intrinsic silver value, whereas electroplated silver presents a budget-friendly option with less precious metal content and lower resale value.

Applications in Jewelry and Household Items

Rolled silver, known for its higher silver content and durability, is commonly used in fine jewelry and high-quality household items like cutlery and decorative pieces, offering better longevity and a premium finish. Electroplated silver, characterized by a thin layer of silver over a base metal, is ideal for affordable costume jewelry and decorative household items where cost-efficiency outweighs long-term wear. The choice between rolled and electroplated silver directly impacts the item's aesthetic appeal, durability, and price in both jewelry and home decor markets.

Maintenance and Care Requirements

Rolled silver, composed of a thick layer of pure silver fused onto a base metal, requires regular gentle cleaning with a soft cloth and mild silver polish to maintain its luster and prevent tarnishing. Electroplated silver has a much thinner silver coating that is more susceptible to wear, demanding extra caution to avoid abrasive cleaners and frequent polishing, which can damage the plating over time. Proper storage in anti-tarnish bags and minimizing exposure to moisture and air extend the lifespan of both rolled and electroplated silver items.

Longevity and Tarnish Resistance

Rolled silver, also known as silver-clad, features a thick outer layer of pure silver fused to a base metal, providing greater longevity and superior tarnish resistance compared to electroplated silver. Electroplated silver consists of a thin silver coating applied through an electrochemical process, which wears off more quickly, exposing the underlying metal and increasing susceptibility to tarnishing. For items requiring durable silver surfaces with prolonged aesthetic appeal, rolled silver is the preferred choice due to its enhanced durability and resistance to corrosion.

Choosing Between Rolled Silver and Electroplated Silver

Choosing between rolled silver and electroplated silver depends on durability and appearance preferences, with rolled silver offering greater thickness and longevity due to its solid silver layer bonded to a base metal. Electroplated silver involves a thinner silver coating applied through an electric current, making it more affordable but prone to wear and tarnish over time. For heirloom quality or frequent use, rolled silver is preferred, while electroplated silver suits decorative or occasional-use items.

Rolled Silver vs Electroplated Silver Infographic

materialdif.com

materialdif.com