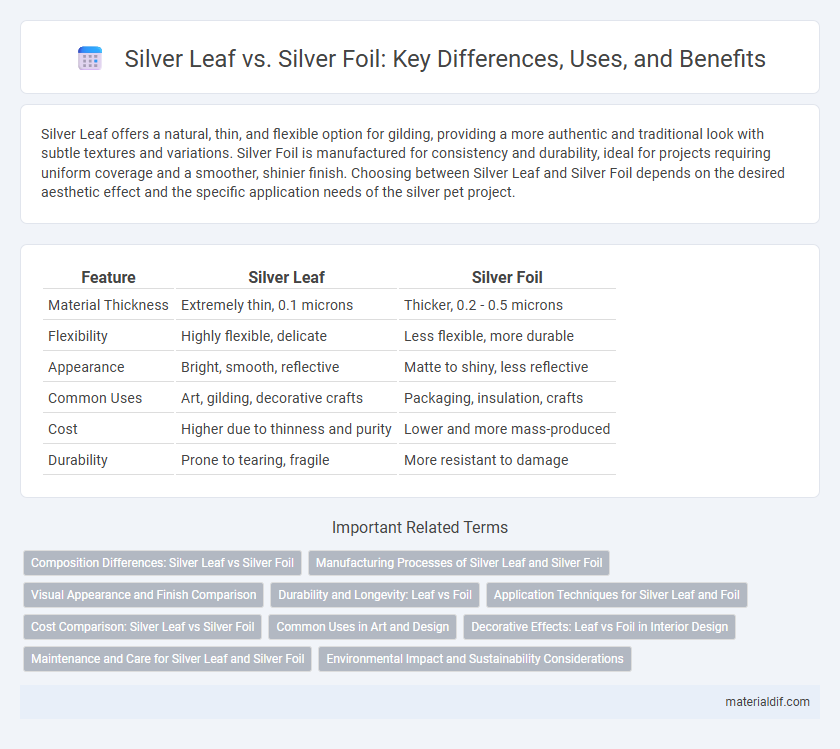

Silver Leaf offers a natural, thin, and flexible option for gilding, providing a more authentic and traditional look with subtle textures and variations. Silver Foil is manufactured for consistency and durability, ideal for projects requiring uniform coverage and a smoother, shinier finish. Choosing between Silver Leaf and Silver Foil depends on the desired aesthetic effect and the specific application needs of the silver pet project.

Table of Comparison

| Feature | Silver Leaf | Silver Foil |

|---|---|---|

| Material Thickness | Extremely thin, 0.1 microns | Thicker, 0.2 - 0.5 microns |

| Flexibility | Highly flexible, delicate | Less flexible, more durable |

| Appearance | Bright, smooth, reflective | Matte to shiny, less reflective |

| Common Uses | Art, gilding, decorative crafts | Packaging, insulation, crafts |

| Cost | Higher due to thinness and purity | Lower and more mass-produced |

| Durability | Prone to tearing, fragile | More resistant to damage |

Composition Differences: Silver Leaf vs Silver Foil

Silver leaf consists of extremely thin sheets of pure silver, often 99.9% fine, designed for delicate gilding work, while silver foil typically includes a silver layer laminated on an adhesive backing or another metal substrate. The purity and thickness variations impact reflectivity and durability, with silver leaf offering higher malleability and a more lustrous finish compared to the more rigid, less pure silver foil. These compositional differences dictate application methods, with silver leaf favored in fine art and restoration, and silver foil used for industrial or decorative purposes where strength and adhesion are critical.

Manufacturing Processes of Silver Leaf and Silver Foil

Silver leaf is crafted using a traditional hammering method that involves repeatedly beating silver into thin sheets, producing ultrathin, delicate layers primarily used in fine art and decoration. Silver foil is manufactured through rolling mills that compress the metal into slightly thicker, more uniform sheets suitable for industrial applications, including electronics and packaging. The key difference lies in the thickness and precision of the production processes, with silver leaf requiring artisanal hammering and foil relying on mechanical rolling technology.

Visual Appearance and Finish Comparison

Silver leaf offers a delicate, ultra-thin aesthetic with a subtle, matte finish that showcases intricate textures and natural variations, enhancing depth and richness. Silver foil, by contrast, presents a smoother, more uniform surface with a reflective, glossy finish that creates a striking, mirror-like shine ideal for bold, contemporary designs. The choice between silver leaf and silver foil significantly impacts the visual appeal, with silver leaf providing a handcrafted, organic look and silver foil delivering sleek, polished elegance.

Durability and Longevity: Leaf vs Foil

Silver leaf offers superior durability and longevity compared to silver foil due to its thicker, more resilient structure, which allows it to withstand environmental factors such as moisture and oxidation more effectively. Silver foil, being thinner and more fragile, tends to tarnish and degrade faster when exposed to air and handling. Consequently, silver leaf is preferred for applications requiring long-lasting metallic finishes with enhanced resistance to wear and corrosion.

Application Techniques for Silver Leaf and Foil

Silver leaf requires meticulous application through gilding techniques, involving adhesive sizing and careful burnishing to achieve a smooth, reflective surface ideal for fine art and restoration projects. Silver foil, being thicker and less delicate, is typically applied using pressure-sensitive adhesives or heat transfer methods, making it suitable for decorative packaging and crafts where durability is essential. Both materials demand precise handling, but silver leaf's ultrathin structure allows for more intricate detailing, while silver foil offers enhanced robustness in diverse industrial and design applications.

Cost Comparison: Silver Leaf vs Silver Foil

Silver leaf is typically more expensive due to its ultra-thin, handcrafted sheets made from pure silver, which require skilled labor and delicate handling. Silver foil, on the other hand, is produced through industrial processes, making it thicker, less refined, and significantly cheaper per square inch. For projects demanding high luxury and intricate detail, the premium price of silver leaf justifies the investment compared to the more cost-effective silver foil option.

Common Uses in Art and Design

Silver leaf offers a delicate, ultra-thin texture ideal for fine art gilding, restoration projects, and detailed calligraphy, providing a genuine metallic shine. Silver foil, thicker and more durable, is commonly used in craft projects, scrapbooking, and decorative packaging where flexibility and ease of handling are essential. Both materials bring a luxurious silver finish but serve distinct functional roles based on their thickness and application methods.

Decorative Effects: Leaf vs Foil in Interior Design

Silver leaf offers a luxurious, hand-applied finish with delicate, irregular textures that create a rich, authentic appearance in interior design. Silver foil provides a smoother, more consistent metallic surface ideal for modern decorative effects and mass production. Both enhance light reflection, but silver leaf excels in artisanal detailing while silver foil suits sleek, uniform aesthetics.

Maintenance and Care for Silver Leaf and Silver Foil

Silver leaf requires delicate handling and gentle cleaning methods such as using a soft, dry cloth to prevent damage due to its thin, fragile nature. Silver foil is more durable and can tolerate light polishing and mild detergent cleaning without compromising its integrity. Both materials should be kept away from moisture and abrasive substances to maintain their luster and prevent tarnishing.

Environmental Impact and Sustainability Considerations

Silver leaf consists of extremely thin sheets of pure silver, which require less energy to produce compared to silver foil that is typically thicker and often alloyed with other metals, resulting in a higher environmental footprint. The production of silver foil involves more intensive mining and refining processes, increasing carbon emissions and resource depletion, whereas silver leaf's minimal material usage promotes better sustainability. Recyclability of silver leaf is higher due to its purity, making it a more eco-friendly option for artists and manufacturers concerned with reducing environmental impact.

Silver Leaf vs Silver Foil Infographic

materialdif.com

materialdif.com