Silk degumming removes the sericin coating from raw silk fibers, enhancing softness and sheen while preserving the fiber's natural strength. Silk scouring involves a more intensive cleaning process that eliminates impurities like oils, waxes, and dirt, preparing the fabric for dyeing and finishing. Both processes improve silk's texture and dye absorption but differ in their treatment intensity and purpose.

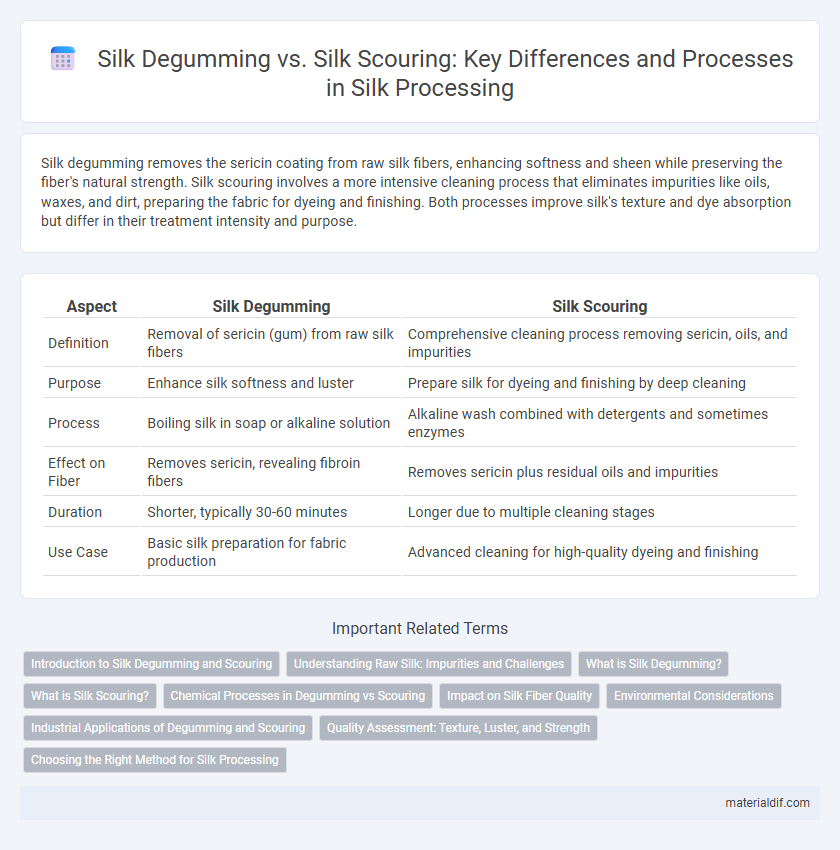

Table of Comparison

| Aspect | Silk Degumming | Silk Scouring |

|---|---|---|

| Definition | Removal of sericin (gum) from raw silk fibers | Comprehensive cleaning process removing sericin, oils, and impurities |

| Purpose | Enhance silk softness and luster | Prepare silk for dyeing and finishing by deep cleaning |

| Process | Boiling silk in soap or alkaline solution | Alkaline wash combined with detergents and sometimes enzymes |

| Effect on Fiber | Removes sericin, revealing fibroin fibers | Removes sericin plus residual oils and impurities |

| Duration | Shorter, typically 30-60 minutes | Longer due to multiple cleaning stages |

| Use Case | Basic silk preparation for fabric production | Advanced cleaning for high-quality dyeing and finishing |

Introduction to Silk Degumming and Scouring

Silk degumming is the essential process of removing sericin, the gummy protein that binds silk fibers, to enhance the fabric's softness and luster. Silk scouring extends beyond degumming by cleansing the silk of natural impurities, oils, and dirt, resulting in a purer and more absorbent material. Both processes are critical for preparing raw silk for dyeing, finishing, and textile manufacturing, ensuring optimal quality and performance.

Understanding Raw Silk: Impurities and Challenges

Silk degumming removes sericin, the natural gum coating raw silk fibers, revealing the smooth fibroin core essential for softness and luster. Silk scouring targets residual impurities such as dirt, oils, and waxes left after degumming, enhancing fabric absorbency and dye affinity. Effective degumming and scouring processes improve the quality and durability of raw silk, addressing challenges linked to its natural impurities.

What is Silk Degumming?

Silk degumming is the process of removing sericin, the gummy protein that coats silk fibers, to reveal the soft, lustrous fibroin underneath. This treatment enhances the silk's texture, dye affinity, and overall quality by eliminating impurities and increasing fiber absorbency. Unlike silk scouring, which involves a more intense cleaning step including degumming, degumming specifically targets the sericin removal essential for producing refined silk fabric.

What is Silk Scouring?

Silk scouring is the process of thoroughly cleaning raw silk fibers to remove natural impurities like sericin, wax, and oils that remain after degumming. This cleaning enhances silk's luster, softness, and dye absorption by preparing the fibers for further processing. Compared to degumming, which primarily targets sericin removal, scouring ensures a more comprehensive purification essential for high-quality textile production.

Chemical Processes in Degumming vs Scouring

Silk degumming involves the removal of sericin, the gummy protein coating silk fibers, primarily using mild alkaline solutions or proteolytic enzymes to preserve the delicate fibroin structure. Silk scouring, on the other hand, employs stronger alkaline chemicals such as sodium hydroxide and detergents to eliminate natural waxes, pectins, and residual sericin, resulting in a cleaner but more aggressively treated fiber. The chemical process in degumming targets selective protein breakdown, while scouring emphasizes thorough removal of impurities for enhanced wetting and dye absorption.

Impact on Silk Fiber Quality

Silk degumming removes sericin, the gummy protein coating silk fibers, enhancing softness, luster, and dye absorption while preserving fiber strength. Silk scouring involves thorough cleansing with alkaline solutions to eliminate impurities but can weaken fibers if over-processed, reducing tensile strength and elasticity. Properly controlled degumming maintains optimal fiber quality, whereas aggressive scouring risks fiber damage, affecting silk's durability and texture.

Environmental Considerations

Silk degumming primarily removes sericin using hot water and mild enzymes, producing wastewater rich in proteins that can be treated biologically to minimize environmental impact. Silk scouring involves stronger alkaline treatments to eliminate impurities such as waxes and oils, resulting in higher chemical and water consumption and more challenging effluent management. Choosing eco-friendly enzymes for degumming and adopting closed-loop water systems in scouring significantly reduce water pollution and energy use in silk processing.

Industrial Applications of Degumming and Scouring

Silk degumming involves removing sericin to enhance the fiber's luster and softness, critical for producing high-quality textiles in industries such as fashion and upholstery. Silk scouring, a more intensive process, eliminates residual waxes, proteins, and impurities, ensuring superior dye absorption and fabric strength for industrial use in high-performance apparel and technical textiles. Both processes are essential in textile manufacturing, with degumming optimizing silk purity while scouring prepares fibers for specialized treatments and coatings.

Quality Assessment: Texture, Luster, and Strength

Silk degumming removes sericin from raw silk, enhancing texture smoothness, increasing fiber luster, and slightly improving tensile strength by exposing fibroin fibers. Silk scouring goes further by cleaning residual impurities and oils, resulting in a brighter luster and a more uniform surface texture, which supports consistent strength and durability. Quality assessment after degumming and scouring typically measures changes in silk fiber smoothness, increased brightness using gloss meters, and tensile strength tests to ensure fabric integrity for high-end textile applications.

Choosing the Right Method for Silk Processing

Silk degumming removes sericin, the natural gum coating silk fibers, to enhance softness and sheen, while silk scouring involves a more intensive cleaning process to eliminate impurities such as oils, waxes, and dirt. Selecting the appropriate method depends on the desired fabric quality and end-use; degumming preserves the silk's natural luster and strength, ideal for high-end textile production, whereas scouring ensures thorough cleanliness for applications requiring additional dyeing or finishing. Understanding the differences in chemical treatments and processing times helps optimize silk processing for maximum fabric performance and aesthetic appeal.

Silk degumming vs Silk scouring Infographic

materialdif.com

materialdif.com