Raw silk contains sericin, a natural gum that makes the fibers coarser and less lustrous, while reeled silk is made by carefully unwinding long silk filaments, resulting in smoother, finer, and more uniform threads. Reeled silk is prized for its glossy appearance and strength, ideal for high-quality textiles, whereas raw silk retains sericin, giving it a textured finish suited for rustic or heavier fabric applications. Understanding the differences between raw and reeled silk helps in selecting the right type for specific textile needs based on texture, durability, and sheen.

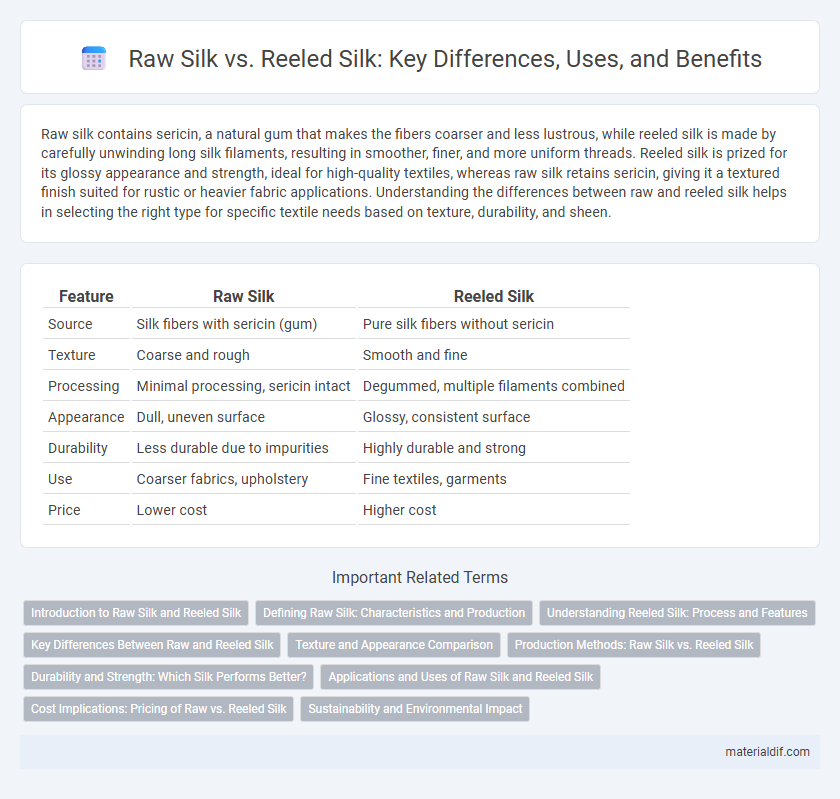

Table of Comparison

| Feature | Raw Silk | Reeled Silk |

|---|---|---|

| Source | Silk fibers with sericin (gum) | Pure silk fibers without sericin |

| Texture | Coarse and rough | Smooth and fine |

| Processing | Minimal processing, sericin intact | Degummed, multiple filaments combined |

| Appearance | Dull, uneven surface | Glossy, consistent surface |

| Durability | Less durable due to impurities | Highly durable and strong |

| Use | Coarser fabrics, upholstery | Fine textiles, garments |

| Price | Lower cost | Higher cost |

Introduction to Raw Silk and Reeled Silk

Raw silk, also known as waste silk, contains sericin and has a coarser texture with natural impurities, making it less lustrous than reeled silk. Reeled silk is produced by carefully unwinding continuous silk filaments from the cocoon, resulting in smooth, shiny fibers prized for luxury textiles. The distinction between raw and reeled silk lies in their processing methods, fiber quality, and end-use applications in fashion and upholstery.

Defining Raw Silk: Characteristics and Production

Raw silk, characterized by its natural, unprocessed state, retains sericin, the natural gum that binds silk fibers, giving it a slightly rough texture and matte appearance. Its production involves carefully harvesting silk cocoons followed by minimal processing, preserving the sericin to enhance durability and texture. In contrast to reeled silk, which is carefully unwound from cocoons into long, smooth threads, raw silk offers a more textured and rustic quality favored in certain textile applications.

Understanding Reeled Silk: Process and Features

Reeled silk is produced by carefully unwinding long continuous filaments from silkworm cocoons, resulting in smooth, strong fibers ideal for high-quality textiles. This process preserves the silk's natural luster and durability, distinguishing it from raw silk, which contains shorter fibers, sericin, and uneven texture. The refined characteristics of reeled silk, such as uniform thickness and enhanced sheen, make it the preferred choice for premium silk fabrics and luxury garments.

Key Differences Between Raw and Reeled Silk

Raw silk contains sericin, the natural gum that coats the fiber, resulting in a coarser texture and a more matte appearance. Reeled silk is carefully extracted by unwinding continuous filaments from silkworm cocoons, producing a smoother, stronger fabric with a lustrous finish. These differences affect the durability, sheen, and tactile quality, making reeled silk preferable for fine garments and raw silk ideal for textured and rustic textile applications.

Texture and Appearance Comparison

Raw silk exhibits a coarser texture with natural sericin coated fibers, resulting in a matte finish and slight irregularities in thickness that enhance its rustic charm. Reeled silk is smoother and finer due to the removal of sericin during reeling, providing a lustrous appearance with uniform strands that reflect light evenly. The textural differences significantly influence the tactile feel and visual appeal, with reeled silk preferred for luxury garments and raw silk favored for artisanal and natural aesthetics.

Production Methods: Raw Silk vs. Reeled Silk

Raw silk is produced by carefully unraveling the silk filament with the sericin gum intact, often resulting in a coarser texture due to the presence of uneven fibers and sericin. Reeled silk involves a meticulous process of extracting continuous filaments from multiple cocoons, removing sericin entirely to produce a smoother, finer fabric. The production method directly influences the texture, strength, and luster of the resulting silk fabric.

Durability and Strength: Which Silk Performs Better?

Raw silk contains natural sericin, making it slightly rougher but more durable and resistant to wear, while reeled silk is smoother and finer with higher tensile strength due to the removal of sericin. Durability in raw silk excels for heavy-use textiles where toughness is crucial, whereas reeled silk's superior strength benefits delicate, lightweight fabrics requiring resilience without bulk. Overall, reeled silk performs better in tensile strength, while raw silk offers enhanced durability under abrasion.

Applications and Uses of Raw Silk and Reeled Silk

Raw silk, characterized by its coarse texture and natural sericin coating, is predominantly used in upholstery, carpets, and heavy fabrics where durability is essential. Reeled silk, known for its smoothness and fine texture after sericin removal, is ideal for high-end textiles, garments, and luxury accessories that require softness and luster. In industries such as fashion and interior design, reeled silk is preferred for delicate fabrics and intricate weaving, while raw silk supports robust and textured material applications.

Cost Implications: Pricing of Raw vs. Reeled Silk

Raw silk generally costs less than reeled silk due to its less refined processing and the presence of sericin, which adds weight but reduces purity. Reeled silk, produced by carefully unwinding silk filaments from cocoons, commands higher prices because of its superior quality, smoothness, and uniformity. Pricing differences also reflect the labor-intensive reeled silk extraction process and the enhanced durability of the finished fabric.

Sustainability and Environmental Impact

Raw silk production retains sericin, requiring less chemical processing and reducing water pollution compared to reeled silk, which involves degumming to remove sericin, leading to higher water and energy usage. Reeled silk yields smoother fibers suitable for luxury textiles but generates more industrial waste and greenhouse gas emissions during processing. Sustainable practices in raw silk harvesting promote biodiversity and minimize deforestation, while reeled silk's intensive mechanical methods pose greater environmental challenges.

Raw silk vs Reeled silk Infographic

materialdif.com

materialdif.com