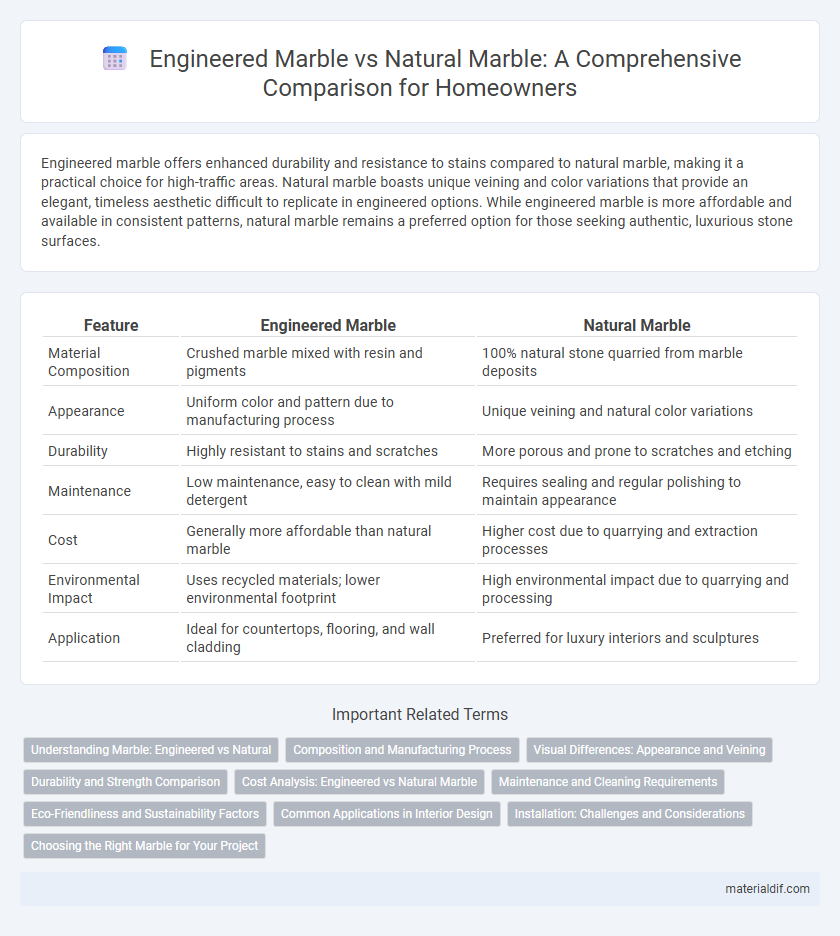

Engineered marble offers enhanced durability and resistance to stains compared to natural marble, making it a practical choice for high-traffic areas. Natural marble boasts unique veining and color variations that provide an elegant, timeless aesthetic difficult to replicate in engineered options. While engineered marble is more affordable and available in consistent patterns, natural marble remains a preferred option for those seeking authentic, luxurious stone surfaces.

Table of Comparison

| Feature | Engineered Marble | Natural Marble |

|---|---|---|

| Material Composition | Crushed marble mixed with resin and pigments | 100% natural stone quarried from marble deposits |

| Appearance | Uniform color and pattern due to manufacturing process | Unique veining and natural color variations |

| Durability | Highly resistant to stains and scratches | More porous and prone to scratches and etching |

| Maintenance | Low maintenance, easy to clean with mild detergent | Requires sealing and regular polishing to maintain appearance |

| Cost | Generally more affordable than natural marble | Higher cost due to quarrying and extraction processes |

| Environmental Impact | Uses recycled materials; lower environmental footprint | High environmental impact due to quarrying and processing |

| Application | Ideal for countertops, flooring, and wall cladding | Preferred for luxury interiors and sculptures |

Understanding Marble: Engineered vs Natural

Engineered marble consists of crushed natural marble mixed with resins and pigments, offering enhanced durability and uniformity compared to natural marble, which is a metamorphic rock formed over millions of years with unique veining and color variations. While natural marble is prized for its authentic beauty and timeless appeal, engineered marble provides increased resistance to stains, scratches, and moisture, making it ideal for high-traffic areas. Choosing between engineered and natural marble depends on maintenance preferences, budget constraints, and desired aesthetic characteristics.

Composition and Manufacturing Process

Engineered marble consists of crushed natural marble combined with resins, pigments, and binders, creating a durable and uniform surface, while natural marble is a metamorphic rock formed through the recrystallization of limestone under high pressure and temperature. The manufacturing process of engineered marble involves mixing raw materials and curing them under controlled conditions to achieve consistent texture and color, whereas natural marble is quarried directly from geological formations and requires cutting and polishing. Engineered marble offers enhanced resistance to stains and scratches due to its synthetic components, contrasting with natural marble's porous and variable structure.

Visual Differences: Appearance and Veining

Engineered marble exhibits a consistent color palette and uniform veining patterns due to its manufactured composition, making it ideal for modern, sleek designs. Natural marble displays unique, irregular veining and a varied color spectrum resulting from natural mineral deposits, offering a distinct and authentic aesthetic. The visual differences in veining and appearance between engineered and natural marble significantly impact design choices and overall ambiance in interior spaces.

Durability and Strength Comparison

Engineered marble offers enhanced durability due to its composite structure, combining crushed natural marble with resins and pigments, making it more resistant to cracks, chips, and stains compared to natural marble. Natural marble, while praised for its unique veining and aesthetic appeal, is more porous and softer, resulting in higher susceptibility to scratches, etching, and weathering over time. In terms of strength, engineered marble provides consistent performance and greater impact resistance, making it ideal for high-traffic surfaces, whereas natural marble requires more maintenance to preserve its structural integrity.

Cost Analysis: Engineered vs Natural Marble

Engineered marble typically costs between $40 to $70 per square foot, offering a more budget-friendly option compared to natural marble, which ranges from $50 to $150 per square foot, depending on the marble variety and source. The installation expenses for engineered marble are generally lower due to its uniformity and easier handling, while natural marble requires skilled labor, increasing overall costs. Maintenance and long-term durability also impact cost-effectiveness, with engineered marble resisting stains and scratches better than porous natural marble, potentially reducing repair and upkeep expenses.

Maintenance and Cleaning Requirements

Engineered marble requires minimal maintenance due to its non-porous surface, making it highly resistant to stains and easier to clean with mild soap and water. Natural marble, being porous, demands regular sealing to protect against stains and etching, and requires specialized cleaners to maintain its polished finish. Routine cleaning and prompt spill management are crucial for preserving the longevity of both materials, but engineered marble offers a more durable and low-maintenance option for busy households.

Eco-Friendliness and Sustainability Factors

Engineered marble offers enhanced eco-friendliness compared to natural marble by utilizing recycled stone and resins, reducing the demand for quarrying and minimizing environmental disruption. Natural marble extraction involves significant energy consumption and habitat disturbance, contributing to higher carbon footprints, whereas engineered marble's manufacturing processes are optimized for resource efficiency. Sustainable construction projects benefit from engineered marble's consistent quality and lower waste generation, supporting green building certifications and long-term environmental goals.

Common Applications in Interior Design

Engineered marble is widely used for kitchen countertops, bathroom vanities, and wall cladding due to its durability, non-porous surface, and consistent patterns, making it ideal for high-traffic areas. Natural marble is favored for flooring, fireplace surrounds, and decorative accents where unique veining and luxurious aesthetics enhance interior elegance. Both materials complement interior design by offering diverse textures and finishes suitable for modern and classic styles.

Installation: Challenges and Considerations

Engineered marble offers greater ease of installation compared to natural marble due to its uniformity and consistent thickness, reducing the need for complex cutting and fitting. Natural marble, while prized for its unique veining, requires skilled craftsmanship to handle its variable thickness and fragile edges, increasing installation time and costs. Proper subfloor preparation and moisture control are critical for both materials to prevent cracking or adhesive failure during and after installation.

Choosing the Right Marble for Your Project

Engineered marble offers enhanced durability and uniformity, making it ideal for high-traffic areas and custom designs. Natural marble provides unique veining and authentic elegance, preferred for luxury applications and classic aesthetics. Selecting the right marble depends on project requirements, budget, maintenance expectations, and desired visual impact.

Engineered Marble vs Natural Marble Infographic

materialdif.com

materialdif.com