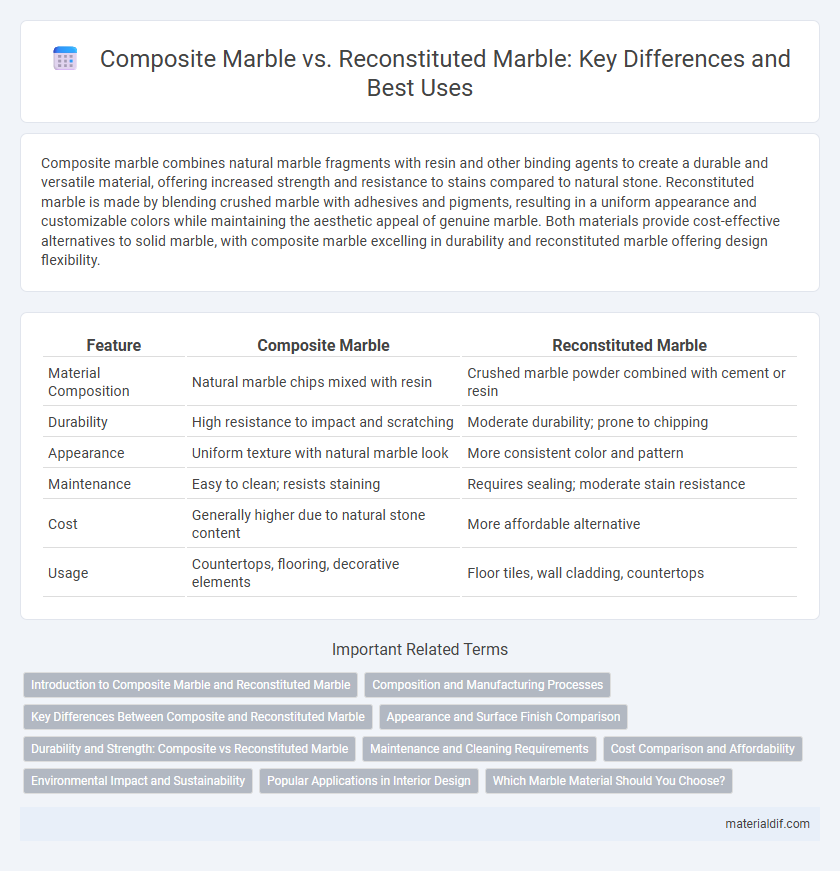

Composite marble combines natural marble fragments with resin and other binding agents to create a durable and versatile material, offering increased strength and resistance to stains compared to natural stone. Reconstituted marble is made by blending crushed marble with adhesives and pigments, resulting in a uniform appearance and customizable colors while maintaining the aesthetic appeal of genuine marble. Both materials provide cost-effective alternatives to solid marble, with composite marble excelling in durability and reconstituted marble offering design flexibility.

Table of Comparison

| Feature | Composite Marble | Reconstituted Marble |

|---|---|---|

| Material Composition | Natural marble chips mixed with resin | Crushed marble powder combined with cement or resin |

| Durability | High resistance to impact and scratching | Moderate durability; prone to chipping |

| Appearance | Uniform texture with natural marble look | More consistent color and pattern |

| Maintenance | Easy to clean; resists staining | Requires sealing; moderate stain resistance |

| Cost | Generally higher due to natural stone content | More affordable alternative |

| Usage | Countertops, flooring, decorative elements | Floor tiles, wall cladding, countertops |

Introduction to Composite Marble and Reconstituted Marble

Composite marble consists of natural marble fragments combined with resin and pigments to create durable, versatile slabs that mimic the appearance of natural stone while reducing cost. Reconstituted marble is made by crushing natural marble into fine particles, mixing it with binding agents, and molding it into slabs, offering consistent patterns and enhanced structural integrity. Both materials provide eco-friendly alternatives to solid marble, with composite marble emphasizing flexibility in design and reconstituted marble focusing on uniformity and strength.

Composition and Manufacturing Processes

Composite marble consists of natural marble chips bound together with resin or cement, producing a durable yet versatile material ideal for various applications. Reconstituted marble, made by crushing natural marble into powder and mixing it with binders like epoxy or polyester resins, undergoes a casting process that allows for consistent texture and color. The manufacturing process of composite marble involves combining raw materials and curing, while reconstituted marble requires precise blending, molding, and polishing to achieve its finished appearance.

Key Differences Between Composite and Reconstituted Marble

Composite marble consists of natural marble chips combined with resins and pigments, offering enhanced durability and varied design options. Reconstituted marble is made by binding crushed marble fragments with a high-density resin, resulting in a uniform appearance and increased resistance to stains and scratches. Key differences include composite marble's more diverse color range and flexibility in shaping, while reconstituted marble provides a consistent texture and improved structural integrity for countertops and flooring.

Appearance and Surface Finish Comparison

Composite marble features a consistent, uniform appearance with customizable colors and patterns due to its blend of natural marble chips and resin, allowing for smooth, glossy surface finishes that resist staining and scratching. Reconstituted marble, made by mixing crushed marble powder with binding agents, offers a more natural stone look with subtle veining and variations, but its surface finish may be less glossy and require more maintenance to preserve its sheen. Both types provide durable, aesthetically appealing options, with composite marble excelling in uniformity and finish resilience, while reconstituted marble emphasizes authentic stone texture and visual depth.

Durability and Strength: Composite vs Reconstituted Marble

Composite marble typically exhibits superior durability and strength due to its blend of natural marble chips and resin binders, resulting in enhanced resistance to cracking and chipping compared to reconstituted marble. Reconstituted marble, made by combining marble dust with cement or resin, tends to have lower tensile strength and can be more prone to surface wear and impact damage under heavy use. These differences make composite marble a preferred choice for high-traffic areas requiring long-lasting surfaces with robust structural integrity.

Maintenance and Cleaning Requirements

Composite marble requires less frequent sealing and is more resistant to staining compared to reconstituted marble, making its maintenance simpler. Reconstituted marble often needs regular sealing and specialized cleaning products to preserve its appearance and prevent surface damage. Both types benefit from wiping spills promptly, but composite marble offers greater ease for routine cleaning and long-term upkeep.

Cost Comparison and Affordability

Composite marble generally offers a more affordable option compared to reconstituted marble due to its lower production costs and use of resin binders mixed with natural stone aggregates. Reconstituted marble involves a more complex manufacturing process, combining crushed marble with resins and pigments, which typically increases its price point. For budget-conscious projects, composite marble presents a cost-effective choice without significantly compromising on aesthetic appeal and durability.

Environmental Impact and Sustainability

Composite marble combines natural marble chips with resin, resulting in a durable surface but involving synthetic materials that may release VOCs and complicate recycling processes. Reconstituted marble, made from crushed marble waste mixed with cement or resin, promotes sustainability by utilizing industrial by-products and reducing quarrying waste, yet energy consumption in manufacturing remains significant. Both materials offer eco-friendly alternatives to natural marble extraction, but their environmental impact varies based on resin content, recyclability, and production energy intensity.

Popular Applications in Interior Design

Composite marble, known for its durability and versatility, is widely used for kitchen countertops, bathroom vanities, and wall cladding due to its resistance to stains and impact. Reconstituted marble, crafted from crushed natural marble mixed with resins, excels in decorative elements such as floor tiles, tabletops, and intricate moldings, offering a cost-effective alternative with a consistent appearance. Interior designers favor composite marble for high-traffic areas and reconstituted marble for customized, elegant finishes that mimic natural stone.

Which Marble Material Should You Choose?

Composite marble, made from a blend of natural marble chips and resin, offers greater durability and resistance to stains compared to reconstituted marble, which is formed by binding ground marble particles with cement or resin. Reconstituted marble provides a more uniform appearance and is often more cost-effective, but it may require more maintenance due to its porosity. Choose composite marble for high-traffic areas needing durability and reconstituted marble for budget-friendly options with customizable aesthetics.

Composite Marble vs Reconstituted Marble Infographic

materialdif.com

materialdif.com