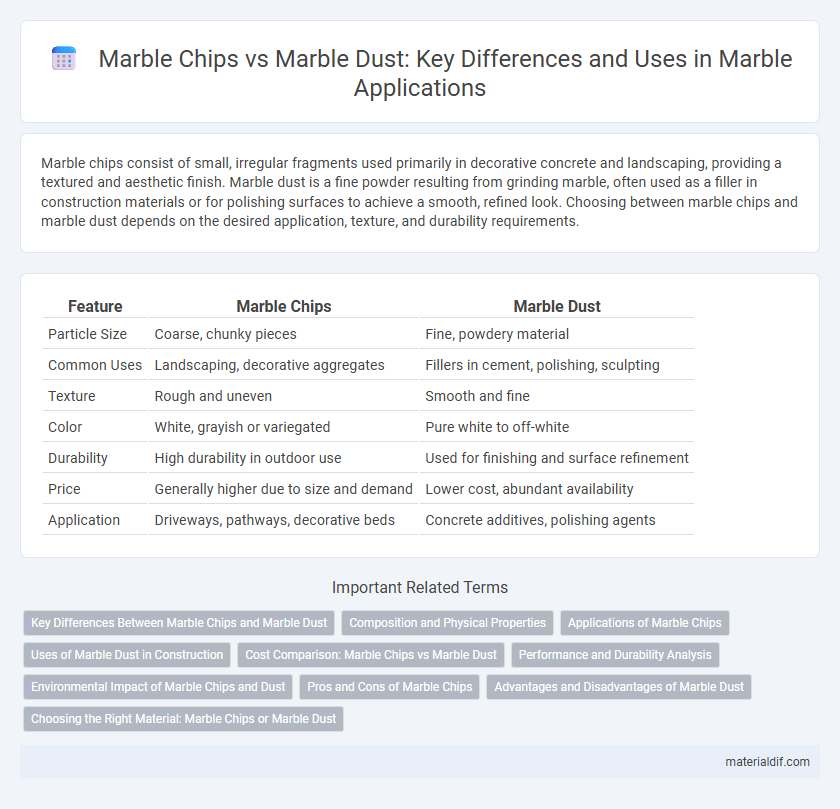

Marble chips consist of small, irregular fragments used primarily in decorative concrete and landscaping, providing a textured and aesthetic finish. Marble dust is a fine powder resulting from grinding marble, often used as a filler in construction materials or for polishing surfaces to achieve a smooth, refined look. Choosing between marble chips and marble dust depends on the desired application, texture, and durability requirements.

Table of Comparison

| Feature | Marble Chips | Marble Dust |

|---|---|---|

| Particle Size | Coarse, chunky pieces | Fine, powdery material |

| Common Uses | Landscaping, decorative aggregates | Fillers in cement, polishing, sculpting |

| Texture | Rough and uneven | Smooth and fine |

| Color | White, grayish or variegated | Pure white to off-white |

| Durability | High durability in outdoor use | Used for finishing and surface refinement |

| Price | Generally higher due to size and demand | Lower cost, abundant availability |

| Application | Driveways, pathways, decorative beds | Concrete additives, polishing agents |

Key Differences Between Marble Chips and Marble Dust

Marble chips are small, irregularly shaped stones used primarily in decorative landscaping and terrazzo flooring, while marble dust consists of fine powder byproduct from marble cutting and polishing, often utilized in fillers, grouts, and repair materials. The key differences lie in particle size, texture, and application: marble chips provide structural integrity and visual appeal, whereas marble dust enhances surface smoothness and bonding properties. Understanding these distinctions is crucial for selecting the right material in construction, sculpture, or landscaping projects.

Composition and Physical Properties

Marble chips are irregularly shaped fragments primarily composed of calcite (CaCO3) with a crystalline structure, offering high compressive strength and durability. Marble dust consists of finely ground particles of the same calcite composition but exhibits a powdery texture that enhances binding properties when mixed with cement or resin. The physical difference in particle size impacts porosity, surface area, and application suitability, with chips favored for decorative aggregate uses and dust for fillers or polishing agents.

Applications of Marble Chips

Marble chips are widely used in construction for decorative concrete, terrazzo flooring, and landscaping due to their durability and aesthetic appeal. Their larger particle size provides excellent drainage and structural stability in pathways, driveways, and garden beds. Unlike marble dust, marble chips offer enhanced slip resistance and a visually striking texture, making them ideal for both functional and ornamental applications.

Uses of Marble Dust in Construction

Marble dust is extensively used in construction for producing high-quality terrazzo floors and decorative elements due to its fine, consistent texture. It enhances the strength and finish of cement-based products, acting as a valuable filler that improves durability and aesthetic appeal. Unlike marble chips, marble dust is ideal for intricate moldings, grout, and plaster, offering a smoother, more refined finish in architectural details.

Cost Comparison: Marble Chips vs Marble Dust

Marble chips generally cost more than marble dust due to their larger size and processing requirements, making them suitable for decorative and structural applications. Marble dust is more affordable, often used as a filler or binder in construction and sculpture, offering economical advantages for bulk projects. The choice between marble chips and marble dust depends on budget constraints and specific project needs, with chips providing aesthetic appeal and dust offering cost efficiency.

Performance and Durability Analysis

Marble chips provide superior structural integrity and enhanced load-bearing capacity due to their larger particle size, contributing to increased performance in construction applications. Marble dust, with its finer particles, offers excellent workability and a smooth finish but may compromise durability under heavy stress or abrasion. Selecting marble chips is ideal for projects demanding high durability and impact resistance, while marble dust suits decorative and surface-level applications where aesthetic quality is prioritized.

Environmental Impact of Marble Chips and Dust

Marble chips generate less airborne particulate matter compared to marble dust, significantly reducing respiratory hazards and environmental pollution during extraction and processing. Marble dust, consisting of finer particles, poses higher risks of soil and water contamination due to its susceptibility to dispersion and runoff. Effective management strategies are essential to mitigate the environmental footprint of both marble chips and dust in construction and manufacturing industries.

Pros and Cons of Marble Chips

Marble chips provide excellent drainage and aesthetic appeal in landscaping and decorative concrete applications due to their durability and natural shine. However, they can be more expensive and heavier than marble dust, making transportation and installation more challenging. Unlike marble dust, chips are less effective for creating a smooth finish in detailed or delicate surfaces.

Advantages and Disadvantages of Marble Dust

Marble dust offers superior workability and can fill gaps effectively, making it ideal for detailed sculpting and polishing compared to marble chips, which are bulkier and less versatile. However, marble dust poses health risks if inhaled, requiring proper protective equipment during handling, whereas marble chips present fewer respiratory hazards. Its fine texture enhances bonding in mortars and paints but can lead to brittleness if overused, diminishing structural integrity in construction applications.

Choosing the Right Material: Marble Chips or Marble Dust

Marble chips consist of larger, irregularly shaped fragments ideal for decorative aggregate, landscaping, and concrete mixes requiring enhanced texture and drainage. Marble dust, composed of fine, powdery particles, is preferred for filling cracks, creating smooth finishes in plaster, and producing high-quality terrazzo floors due to its ability to blend seamlessly. Selecting between marble chips and marble dust depends on project requirements for aesthetics, texture, and structural integrity.

Marble Chips vs Marble Dust Infographic

materialdif.com

materialdif.com