Waterjet cutting offers superior versatility and precision for intricate marble designs, utilizing high-pressure water mixed with abrasive materials to slice through stone without generating heat. CNC cutting employs computer-controlled tools for shaping marble, providing consistent, clean cuts ideal for large-scale or uniform projects but may produce heat that can cause minor surface imperfections. Choosing between waterjet and CNC cutting depends on the complexity of the design, desired finish quality, and project scale.

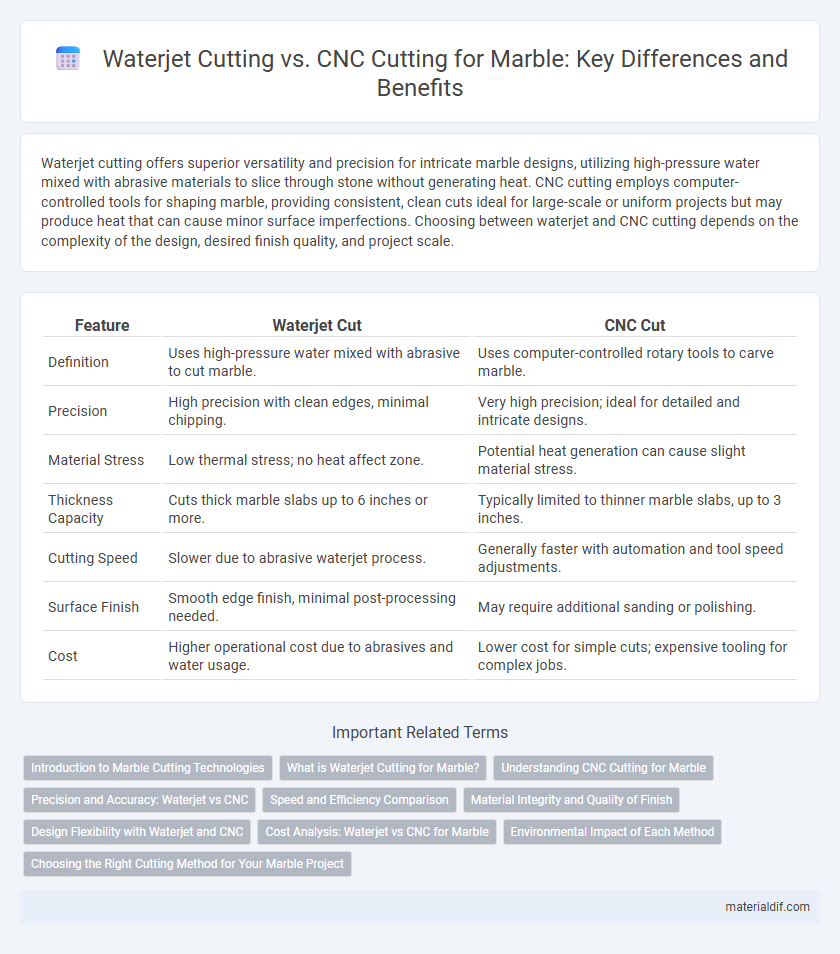

Table of Comparison

| Feature | Waterjet Cut | CNC Cut |

|---|---|---|

| Definition | Uses high-pressure water mixed with abrasive to cut marble. | Uses computer-controlled rotary tools to carve marble. |

| Precision | High precision with clean edges, minimal chipping. | Very high precision; ideal for detailed and intricate designs. |

| Material Stress | Low thermal stress; no heat affect zone. | Potential heat generation can cause slight material stress. |

| Thickness Capacity | Cuts thick marble slabs up to 6 inches or more. | Typically limited to thinner marble slabs, up to 3 inches. |

| Cutting Speed | Slower due to abrasive waterjet process. | Generally faster with automation and tool speed adjustments. |

| Surface Finish | Smooth edge finish, minimal post-processing needed. | May require additional sanding or polishing. |

| Cost | Higher operational cost due to abrasives and water usage. | Lower cost for simple cuts; expensive tooling for complex jobs. |

Introduction to Marble Cutting Technologies

Waterjet cutting technology utilizes high-pressure water mixed with abrasive materials to precisely slice through marble, offering minimal heat generation and preserving the stone's natural integrity. CNC cutting employs computer-controlled rotary tools to carve intricate designs with consistent accuracy, ideal for detailed and repeatable patterns in marble fabrication. Both methods enhance efficiency and precision but differ in their approach to handling the unique properties of marble during the cutting process.

What is Waterjet Cutting for Marble?

Waterjet cutting for marble involves using a high-pressure jet of water mixed with abrasive materials to precisely slice through stone without generating heat, preserving the marble's integrity and preventing cracks. This method allows for intricate designs and smooth edges on marble surfaces, making it ideal for detailed architectural elements and custom countertops. Unlike CNC cutting, which uses mechanical tools and can cause micro-fractures or chipping, waterjet cutting ensures minimal material waste and maintains the natural beauty of marble.

Understanding CNC Cutting for Marble

CNC cutting for marble utilizes computer-controlled routers and diamond-tipped tools to achieve precise and intricate designs with minimal material waste. This method allows for consistent repeatability and high accuracy in shaping slabs, making it ideal for custom countertops, architectural elements, and detailed patterns. Unlike waterjet cutting, CNC cutting offers superior edge finishes and the ability to perform complex 3D carving in marble surfaces.

Precision and Accuracy: Waterjet vs CNC

Waterjet cutting delivers exceptional precision by using high-pressure water mixed with abrasive materials, allowing it to cut intricate marble patterns without heat deformation. CNC cutting offers superior accuracy through computer-controlled milling, enabling precise shaping and detailed designs with repeatability within microns. Both methods ensure high-quality marble craftsmanship, but CNC excels in achieving consistent dimensional accuracy, while waterjet preserves material integrity by avoiding thermal stress.

Speed and Efficiency Comparison

Waterjet cutting offers faster processing speeds for intricate marble designs, achieving precise cuts without heat-affected zones. CNC cutting provides consistent efficiency in producing large, uniform marble slabs but may require more time for complex patterns due to tool changes. Overall, waterjet cutting excels in speed and accuracy for detailed work, while CNC suits high-volume, repetitive tasks efficiently.

Material Integrity and Quality of Finish

Waterjet cutting preserves marble's material integrity by using high-pressure water mixed with abrasive particles, avoiding heat generation and reducing the risk of micro-fractures or thermal damage common in CNC cutting. CNC cutting employs rotary tools that can induce mechanical stress and minor chipping on the marble surface, potentially compromising finish quality and reducing structural strength. The waterjet process ensures a smoother, cleaner edge and superior finish, making it ideal for intricate designs requiring high precision without altering the marble's natural properties.

Design Flexibility with Waterjet and CNC

Waterjet cutting offers superior design flexibility for marble by enabling intricate patterns and delicate curves without heat distortion, preserving the stone's natural integrity. CNC cutting uses computer-controlled routers to provide precise, repeatable cuts ideal for geometric shapes and consistent dimensions but may struggle with complex, freeform designs. The choice depends on project complexity, with waterjet excelling in detailed artistry and CNC suitable for standardized, high-volume production.

Cost Analysis: Waterjet vs CNC for Marble

Waterjet cutting for marble generally incurs higher operational costs due to abrasive material consumption and longer processing times, whereas CNC cutting uses diamond-tipped tools that reduce wear and offer faster throughput, lowering labor expenses. Initial investment for waterjet machinery is typically higher, but CNC machines demand frequent tool replacements that can increase maintenance costs over time. Evaluating total cost of ownership, CNC cutting emerges as more cost-effective for high-volume marble fabrication, while waterjet cutting excels in precision applications despite its elevated price point.

Environmental Impact of Each Method

Waterjet cutting of marble minimizes environmental impact by using high-pressure water mixed with abrasive materials, producing less dust and reducing airborne pollutants compared to CNC cutting, which often generates significant dust and requires more energy-intensive machinery. The water used in waterjet cutting can be recycled and filtered, lowering water consumption and contamination risks, while CNC processes rely on lubricants and coolants that may contribute to hazardous waste. Overall, waterjet cutting offers a cleaner, more sustainable option for marble fabrication with reduced emissions and waste management challenges.

Choosing the Right Cutting Method for Your Marble Project

Selecting the optimal cutting method for marble depends on project precision and detail requirements; waterjet cutting offers exceptional accuracy and clean edges without heat damage, ideal for intricate designs. CNC cutting provides greater speed and efficiency on larger, less detailed pieces, utilizing diamond-tipped tools to carve or shape marble swiftly. Evaluating the complexity, budget, and finish expectations ensures the best choice between waterjet and CNC cutting for durable, high-quality marble results.

Waterjet Cut vs CNC Cut Infographic

materialdif.com

materialdif.com