Recycled concrete aggregate offers a sustainable alternative to virgin gravel by repurposing demolished concrete into a cost-effective, environmentally friendly material for construction projects. It provides comparable strength and durability to virgin gravel while reducing the demand for natural resources and minimizing landfill waste. Choosing recycled concrete aggregate supports eco-conscious building practices without compromising on performance or quality.

Table of Comparison

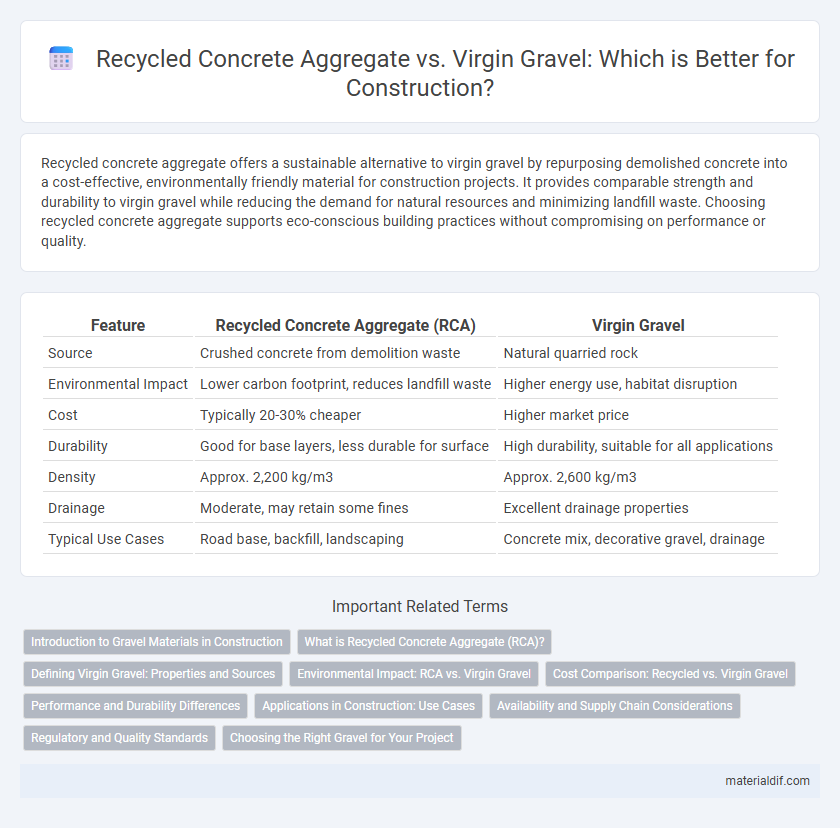

| Feature | Recycled Concrete Aggregate (RCA) | Virgin Gravel |

|---|---|---|

| Source | Crushed concrete from demolition waste | Natural quarried rock |

| Environmental Impact | Lower carbon footprint, reduces landfill waste | Higher energy use, habitat disruption |

| Cost | Typically 20-30% cheaper | Higher market price |

| Durability | Good for base layers, less durable for surface | High durability, suitable for all applications |

| Density | Approx. 2,200 kg/m3 | Approx. 2,600 kg/m3 |

| Drainage | Moderate, may retain some fines | Excellent drainage properties |

| Typical Use Cases | Road base, backfill, landscaping | Concrete mix, decorative gravel, drainage |

Introduction to Gravel Materials in Construction

Recycled concrete aggregate (RCA) offers a sustainable alternative to virgin gravel by repurposing demolished concrete into high-quality construction material. Virgin gravel, naturally sourced from quarries, provides consistent strength and durability essential for foundational and paving applications. Utilizing RCA reduces environmental impact by minimizing landfill waste and conserving natural resources while meeting strict engineering standards.

What is Recycled Concrete Aggregate (RCA)?

Recycled Concrete Aggregate (RCA) is a sustainable construction material produced by crushing and processing demolished concrete structures into usable aggregates. RCA offers an environmentally friendly alternative to virgin gravel by reducing landfill waste and conserving natural resources. It retains similar structural properties to natural gravel, making it ideal for use in road base, drainage systems, and concrete production.

Defining Virgin Gravel: Properties and Sources

Virgin gravel consists of naturally occurring, unprocessed rock fragments extracted directly from quarries or riverbeds, characterized by high durability, angularity, and consistent particle size. Common sources include glacial deposits, river terraces, and sedimentary formations, which contribute to its uniform mineral composition and strength suitable for construction and landscaping. Virgin gravel's physicochemical properties, such as low porosity and high compressive strength, distinguish it from recycled alternatives, making it ideal for load-bearing applications and infrastructure projects.

Environmental Impact: RCA vs. Virgin Gravel

Recycled Concrete Aggregate (RCA) significantly reduces environmental impact by minimizing the need for virgin material extraction, lowering landfill waste, and decreasing carbon emissions associated with quarrying and transportation. Virgin gravel extraction involves extensive land disturbance, habitat disruption, and higher energy consumption, contributing to greater ecological footprint. Utilizing RCA supports sustainable construction practices by promoting resource efficiency and reducing overall environmental degradation compared to virgin gravel.

Cost Comparison: Recycled vs. Virgin Gravel

Recycled concrete aggregate (RCA) typically costs 20-40% less than virgin gravel due to lower material extraction and processing expenses. Transportation costs may further reduce overall spending since RCA sources often originate near urban demolition sites, minimizing haul distances. However, price variability depends on local availability, demand, and quality requirements for specific construction projects.

Performance and Durability Differences

Recycled Concrete Aggregate (RCA) generally exhibits lower density and higher absorption rates compared to virgin gravel, which can impact load-bearing capacity and long-term durability in construction projects. Virgin gravel offers superior performance with enhanced strength and resistance to weathering, making it more suitable for high-stress applications such as road base and foundation layers. While RCA can be cost-effective and environmentally friendly, its variable quality requires careful assessment to ensure it meets durability standards comparable to virgin aggregates.

Applications in Construction: Use Cases

Recycled concrete aggregate (RCA) is increasingly utilized in road base, sub-base layers, and drainage systems due to its cost-effectiveness and environmental benefits, providing comparable strength to virgin gravel. Virgin gravel remains preferred for structural concrete, high-load-bearing applications, and aesthetic landscaping projects where material uniformity and appearance are critical. Both materials support sustainable construction practices, with RCA promoting waste reduction and virgin gravel ensuring durability and consistent performance in specialized uses.

Availability and Supply Chain Considerations

Recycled concrete aggregate (RCA) offers a sustainable alternative with often localized availability, reducing transportation distances and associated carbon emissions compared to virgin gravel, which depends on quarrying and may face depletion risks. Supply chain consistency for RCA can fluctuate due to variable demolition activities and processing capacities, while virgin gravel typically benefits from established, large-scale extraction operations ensuring steadier supply. Evaluating project location and material demand is crucial to balancing cost-efficiency and sustainability when choosing between recycled concrete aggregate and virgin gravel.

Regulatory and Quality Standards

Recycled Concrete Aggregate (RCA) must comply with specific environmental regulations and quality standards such as ASTM C33 and EN 12620 to ensure safety and performance in construction applications. Virgin gravel, sourced directly from natural deposits, is often subject to less stringent regulatory scrutiny but must meet standards like AASHTO M43 for particle size and durability. Regulatory agencies emphasize consistent grading, contamination limits, and mechanical properties in both materials to guarantee structural integrity and environmental compliance.

Choosing the Right Gravel for Your Project

Recycled concrete aggregate offers a sustainable alternative to virgin gravel by reducing landfill waste and lowering environmental impact, while maintaining comparable strength for most construction applications. Virgin gravel, sourced directly from natural deposits, often provides higher durability and better grading consistency, essential for projects requiring precise material specifications. Selecting the right gravel depends on project requirements such as load-bearing capacity, budget constraints, and environmental goals, with recycled aggregate favoring eco-conscious developments and virgin gravel suited for heavy-duty structural uses.

Recycled Concrete Aggregate vs Virgin Gravel Infographic

materialdif.com

materialdif.com