Natural granite is a durable, igneous rock formed through volcanic activity, showcasing unique patterns and color variations created by natural mineral composition. Engineered granite, often composed of crushed natural stone mixed with resins and pigments, offers uniformity and enhanced resistance to stains and scratches compared to its natural counterpart. Choosing between natural and engineered granite depends on desired aesthetics, durability needs, and maintenance preferences.

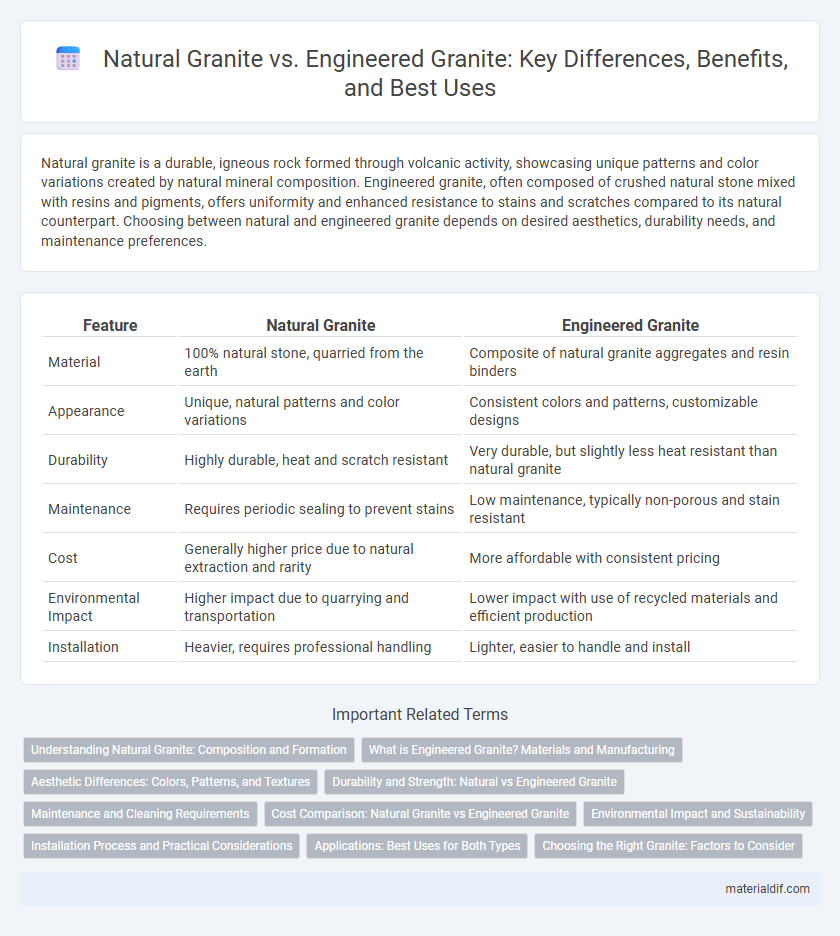

Table of Comparison

| Feature | Natural Granite | Engineered Granite |

|---|---|---|

| Material | 100% natural stone, quarried from the earth | Composite of natural granite aggregates and resin binders |

| Appearance | Unique, natural patterns and color variations | Consistent colors and patterns, customizable designs |

| Durability | Highly durable, heat and scratch resistant | Very durable, but slightly less heat resistant than natural granite |

| Maintenance | Requires periodic sealing to prevent stains | Low maintenance, typically non-porous and stain resistant |

| Cost | Generally higher price due to natural extraction and rarity | More affordable with consistent pricing |

| Environmental Impact | Higher impact due to quarrying and transportation | Lower impact with use of recycled materials and efficient production |

| Installation | Heavier, requires professional handling | Lighter, easier to handle and install |

Understanding Natural Granite: Composition and Formation

Natural granite is an igneous rock primarily composed of quartz, feldspar, and mica, formed through the slow crystallization of magma beneath the Earth's surface. This geological process results in a durable and dense material with unique mineral patterns and color variations, making each slab distinct. The natural formation provides inherent resistance to heat, scratches, and stains, distinguishing it from engineered granite, which is manufactured using resin and crushed stone.

What is Engineered Granite? Materials and Manufacturing

Engineered granite consists of crushed natural granite mixed with resins and pigments, creating a durable surface that mimics natural stone while offering enhanced consistency and color variety. The manufacturing process involves combining these materials under high pressure and heat to form slabs that are non-porous, stain-resistant, and easier to maintain than natural granite. This engineered composite provides a versatile alternative for countertops and architectural surfaces with improved strength and customization options.

Aesthetic Differences: Colors, Patterns, and Textures

Natural granite offers unique, irregular patterns and a wide range of earthy colors, including speckles and veining formed by natural mineral deposits, providing an authentic and organic aesthetic. Engineered granite, composed of crushed natural stone mixed with resin, allows for more uniform patterns and a broader palette, including vibrant, consistent colors and smoother textures that can be customized for specific design needs. The choice between natural and engineered granite ultimately depends on whether one prioritizes natural variation and rustic charm or consistency and color options for modern aesthetics.

Durability and Strength: Natural vs Engineered Granite

Natural granite offers exceptional durability and strength due to its dense mineral composition formed over millions of years, making it highly resistant to scratches, heat, and wear. Engineered granite, composed of crushed natural granite mixed with resin and pigments, provides enhanced uniformity and slightly higher resistance to staining but may lack the extreme durability of natural stone under heavy impact. Both materials are robust choices for countertops, with natural granite preferred for long-term resilience and engineered granite favored for consistency and easier maintenance.

Maintenance and Cleaning Requirements

Natural granite requires periodic sealing to maintain its resistance to stains and moisture, with cleaning typically done using mild soap and water to avoid damage. Engineered granite offers enhanced stain and scratch resistance due to its resin composition, allowing for easier maintenance with non-abrasive cleaners and no need for sealing. Both materials benefit from prompt spill clean-ups to preserve surface integrity and prolong countertop lifespan.

Cost Comparison: Natural Granite vs Engineered Granite

Natural granite typically costs between $40 to $100 per square foot, reflecting its unique geological formation and durability. Engineered granite, often priced from $30 to $70 per square foot, combines crushed natural stone with resins, leading to a more budget-friendly option with consistent patterns. Cost variation depends on factors such as slab size, thickness, fabrication, and region-specific availability.

Environmental Impact and Sustainability

Natural granite is a durable and eco-friendly option, quarried without harmful chemicals but involves significant energy consumption and habitat disruption. Engineered granite, made from crushed stone mixed with resins, offers less environmental impact during extraction but relies on synthetic resins that may emit volatile organic compounds (VOCs). Both materials have different sustainability profiles, with natural granite favored for recyclability and engineered granite for resource efficiency.

Installation Process and Practical Considerations

Natural granite installation demands precise handling due to its substantial weight and inherent variability in patterns, requiring skilled labor to ensure seamless fitting and alignment. Engineered granite simplifies installation with uniform slabs that reduce cutting complexity and minimize waste, making it more cost-efficient and faster to install. Practical considerations include assessing subfloor support for natural granite and choosing engineered granite for consistent performance and easier maintenance in high-traffic or moisture-prone areas.

Applications: Best Uses for Both Types

Natural granite is ideal for kitchen countertops, bathroom vanities, and outdoor applications due to its durability, heat resistance, and unique, natural patterns. Engineered granite excelling in commercial spaces and modern interior design benefits from its consistent colors, enhanced strength, and stain resistance. Both types serve well in flooring and wall cladding, with natural granite preferred for high-traffic outdoor areas and engineered granite favored in controlled indoor environments.

Choosing the Right Granite: Factors to Consider

Natural granite offers unique patterns and superior durability, making it ideal for high-traffic areas, while engineered granite provides consistent color and enhanced resistance to stains. Consider factors such as budget, maintenance requirements, and the specific use case to determine which type best suits your project. Evaluating these elements ensures a balance between aesthetics, longevity, and cost-effectiveness when selecting granite for countertops or flooring.

Natural Granite vs Engineered Granite Infographic

materialdif.com

materialdif.com