Denim stonewashing creates a worn, vintage look by washing fabric with pumice stones, resulting in a softer texture and faded appearance. Enzyme washing uses cellulase enzymes to break down cellulose fibers, producing a smoother finish with less abrasion and environmental impact. Both techniques enhance denim softness and style, but enzyme washing offers a more eco-friendly and controlled fading process.

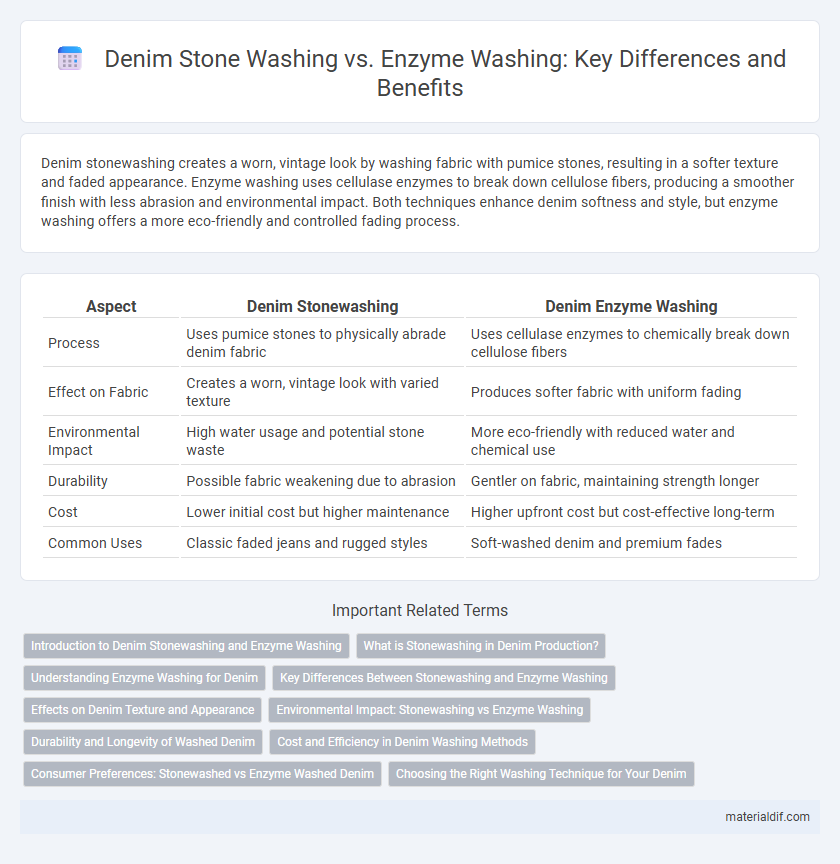

Table of Comparison

| Aspect | Denim Stonewashing | Denim Enzyme Washing |

|---|---|---|

| Process | Uses pumice stones to physically abrade denim fabric | Uses cellulase enzymes to chemically break down cellulose fibers |

| Effect on Fabric | Creates a worn, vintage look with varied texture | Produces softer fabric with uniform fading |

| Environmental Impact | High water usage and potential stone waste | More eco-friendly with reduced water and chemical use |

| Durability | Possible fabric weakening due to abrasion | Gentler on fabric, maintaining strength longer |

| Cost | Lower initial cost but higher maintenance | Higher upfront cost but cost-effective long-term |

| Common Uses | Classic faded jeans and rugged styles | Soft-washed denim and premium fades |

Introduction to Denim Stonewashing and Enzyme Washing

Denim stonewashing uses pumice stones to create a worn, faded look by physically abrading the fabric, resulting in softer texture and vintage appeal. Enzyme washing employs cellulase enzymes to gently break down cellulose fibers, offering a controlled fading effect and improved fabric softness without damaging the denim structure. Both techniques enhance denim's aesthetic and comfort but differ in their environmental impact and processing methods.

What is Stonewashing in Denim Production?

Stonewashing in denim production involves washing jeans with pumice stones to create a worn, faded look and soften the fabric. This traditional technique removes excess dye and produces unique texture variations, enhancing the garment's vintage appeal. Stonewashing is labor-intensive and can be harsher on the denim fibers compared to alternative methods like enzyme washing.

Understanding Enzyme Washing for Denim

Enzyme washing for denim utilizes cellulase enzymes to selectively break down cellulose fibers, creating a soft, worn-in texture while preserving fabric strength compared to traditional stonewashing. This eco-friendly technique reduces water usage and minimizes fabric damage, enhancing denim durability and appearance. Enzyme washing produces subtle fading and color variation, offering a cleaner, more natural finish favored in contemporary denim treatments.

Key Differences Between Stonewashing and Enzyme Washing

Stonewashing uses pumice stones to physically abrade denim fabric, creating a worn, faded look with more texture and potential fabric damage. Enzyme washing employs cellulase enzymes that selectively break down cellulose fibers, resulting in a softer finish and more controlled fading without harsh abrasion. Stonewashing typically produces a rougher, vintage appearance, whereas enzyme washing offers a smoother feel and environmentally friendlier process.

Effects on Denim Texture and Appearance

Denim stonewashing creates a rugged, vintage look by physically abrading the fabric with pumice stones, resulting in a rougher texture and faded, worn-in appearance. Enzyme washing uses cellulase enzymes to break down cellulose fibers, producing a softer texture and more uniform fading without the harsh abrasions typical of stonewashing. This enzymatic process preserves fabric strength while enhancing softness and color variation in the denim.

Environmental Impact: Stonewashing vs Enzyme Washing

Stonewashing denim utilizes pumice stones, which cause significant water pollution and generate high levels of solid waste, posing substantial environmental challenges. Enzyme washing, employing biodegradable cellulase enzymes, significantly reduces water usage and chemical discharge, making it a more sustainable alternative. This process minimizes fabric damage and lowers energy consumption, aligning with eco-friendly production standards in the textile industry.

Durability and Longevity of Washed Denim

Denim stonewashing involves using pumice stones to create a worn, vintage look, which can cause more abrasion and fiber weakening, potentially reducing the durability and longevity of the fabric. Enzyme washing employs cellulase enzymes to gently break down cellulose fibers, preserving fabric strength and enhancing the lifespan of the denim. Choosing enzyme-washed denim typically results in longer-lasting garments with better resistance to wear compared to stonewashed alternatives.

Cost and Efficiency in Denim Washing Methods

Denim stonewashing involves using pumice stones to achieve a faded look, leading to higher labor and material costs due to stone replacement and equipment maintenance. Enzyme washing utilizes cellulase enzymes to selectively break down cellulose fibers, offering greater efficiency with lower water usage and reduced washing time. Enzyme washing generally provides a cost-effective and eco-friendly solution compared to the more resource-intensive and time-consuming stonewashing method.

Consumer Preferences: Stonewashed vs Enzyme Washed Denim

Consumers often prefer stonewashed denim for its classic worn-in look and durable texture, which enhances garment softness over time. Enzyme washed denim appeals to those seeking environmentally friendly options and a gentler, more uniform fade without damage. Market trends indicate a growing shift toward enzyme washing due to sustainability awareness and consistent fabric quality.

Choosing the Right Washing Technique for Your Denim

Denim stonewashing uses pumice stones to create a worn, vintage look by physically abrading the fabric, resulting in a heavier and more textured finish. Enzyme washing employs cellulase enzymes to break down cellulose fibers, producing a softer feel with less environmental impact and greater fabric integrity. Selecting the right washing technique depends on the desired aesthetic, fabric sensitivity, and sustainability priorities in denim production.

Denim Stonewashing vs Enzyme Washing Infographic

materialdif.com

materialdif.com