Core-spun yarn offers enhanced durability and softness compared to traditional yarn, making it ideal for denim pet products that require both comfort and strength. This yarn construction combines a strong synthetic filament wrapped with natural fibers, providing superior resistance to wear and tear. As a result, denim pet items made with core-spun yarn maintain their shape and appearance longer than those made with traditional yarn.

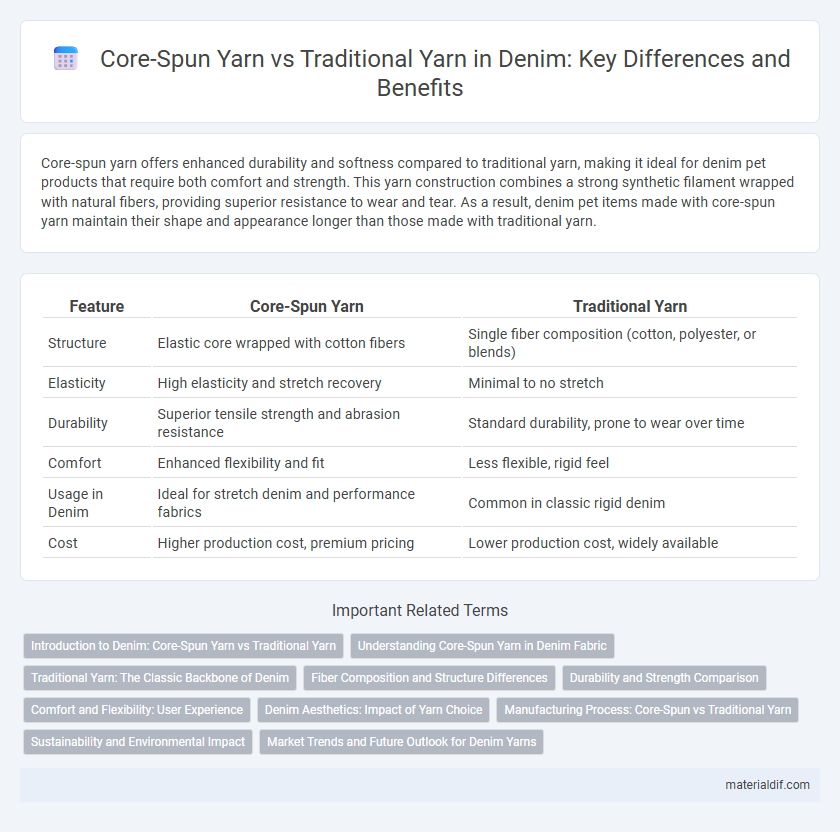

Table of Comparison

| Feature | Core-Spun Yarn | Traditional Yarn |

|---|---|---|

| Structure | Elastic core wrapped with cotton fibers | Single fiber composition (cotton, polyester, or blends) |

| Elasticity | High elasticity and stretch recovery | Minimal to no stretch |

| Durability | Superior tensile strength and abrasion resistance | Standard durability, prone to wear over time |

| Comfort | Enhanced flexibility and fit | Less flexible, rigid feel |

| Usage in Denim | Ideal for stretch denim and performance fabrics | Common in classic rigid denim |

| Cost | Higher production cost, premium pricing | Lower production cost, widely available |

Introduction to Denim: Core-Spun Yarn vs Traditional Yarn

Core-spun yarn enhances denim durability by combining a polyester core with a cotton sheath, providing superior strength and stretch compared to traditional 100% cotton yarn. This hybrid structure reduces fabric pilling and improves resilience, making denim more resistant to wear and tear in everyday use. Traditional yarn, while offering natural breathability and softness, lacks the enhanced tensile strength and elasticity found in core-spun alternatives.

Understanding Core-Spun Yarn in Denim Fabric

Core-spun yarn in denim fabric features a polyester or nylon filament core wrapped with cotton fibers, combining strength and comfort for enhanced durability compared to traditional 100% cotton yarn. This yarn construction improves resistance to abrasion and tearing, making denim garments longer-lasting and better suited for active wear. Core-spun yarn also maintains the authentic look and feel of denim while offering advanced performance properties absent in conventional yarns.

Traditional Yarn: The Classic Backbone of Denim

Traditional yarn, made from 100% cotton fibers, has long been the classic backbone of denim fabric, providing durability, breathability, and authentic texture. This yarn type, spun through conventional ring-spinning techniques, ensures a consistent strength and timeless appeal crucial for high-quality denim production. Its natural fiber composition enhances comfort and wear-resistance, making it a preferred choice for traditional denim garments.

Fiber Composition and Structure Differences

Core-spun yarn features a strong synthetic filament core wrapped with natural cotton fibers, enhancing durability and stretch compared to traditional yarn made entirely of spun cotton fibers. The fiber composition in core-spun yarn provides improved elasticity and resistance to wear, while the traditional yarn's uniform cotton structure offers a softer hand but less tensile strength. Structurally, core-spun yarn's dual-component design creates a balanced fabric ideal for denim requiring both comfort and performance.

Durability and Strength Comparison

Core-spun yarn incorporates a strong filament core wrapped with natural fibers, resulting in enhanced durability and tensile strength compared to traditional yarn composed solely of spun fibers. This construction improves resistance to abrasion and reduces the likelihood of breakage, making core-spun yarn ideal for heavy-duty denim applications. The fiber technology ensures prolonged garment lifespan and maintains structural integrity under frequent wear and washing.

Comfort and Flexibility: User Experience

Core-spun yarn enhances denim comfort by combining a soft polyester or nylon core wrapped in cotton fibers, resulting in increased flexibility and durability compared to traditional 100% cotton yarn. This construction allows denim to stretch and move with the wearer, reducing stiffness and improving overall comfort during prolonged use. Users experience less restriction and greater ease of movement, making core-spun yarn denim ideal for active lifestyles and all-day wear.

Denim Aesthetics: Impact of Yarn Choice

Core-spun yarn enhances denim aesthetics by combining a polyester filament core with cotton fibers, resulting in improved fabric strength and elasticity without sacrificing the natural look and feel of traditional cotton yarn. Traditional yarn, made solely from cotton fibers, offers classic breathability and softness but tends to produce denim with less durability and a more prone-to-abrasion surface. The choice between core-spun and traditional yarn directly influences denim's appearance, texture, and long-term wear characteristics, shaping consumer perception and garment longevity.

Manufacturing Process: Core-Spun vs Traditional Yarn

Core-spun yarn manufacturing involves wrapping a strong synthetic filament around a soft cotton core, enhancing strength and elasticity for denim fabric. Traditional yarn production typically spins fibers uniformly without a central filament, resulting in less durability and stretch. The core-spun process requires specialized ring-spinning machinery, while traditional yarn uses standard spinning techniques.

Sustainability and Environmental Impact

Core-spun yarn combines a polyester or recycled filament core with an outer cotton layer, reducing water and pesticide usage compared to traditional 100% cotton yarn. This innovation decreases environmental impact by minimizing cotton cultivation demands while maintaining denim durability and comfort. Core-spun yarn contributes to sustainable denim production by lowering carbon footprint and enabling efficient resource utilization throughout the manufacturing process.

Market Trends and Future Outlook for Denim Yarns

Core-spun yarn is gaining significant traction in the denim market due to its enhanced strength, durability, and comfort compared to traditional yarns, driving increased adoption in premium denim fabrics. Market trends show a growing preference for eco-friendly and sustainable fibers, with core-spun yarns offering improved performance while supporting sustainable manufacturing practices. The future outlook for denim yarns points to expanded innovation in core-spun technology, meeting rising consumer demand for high-quality, sustainable denim products.

core-spun yarn vs traditional yarn Infographic

materialdif.com

materialdif.com