Silver alloy offers superior durability and resistance to tarnish compared to silver composite, making it ideal for long-lasting silver pet products. Silver composite, often mixed with other materials, provides more flexibility and affordability but may compromise the item's strength and shine over time. Choosing silver alloy ensures a high-quality, elegant finish that maintains its appearance with minimal maintenance.

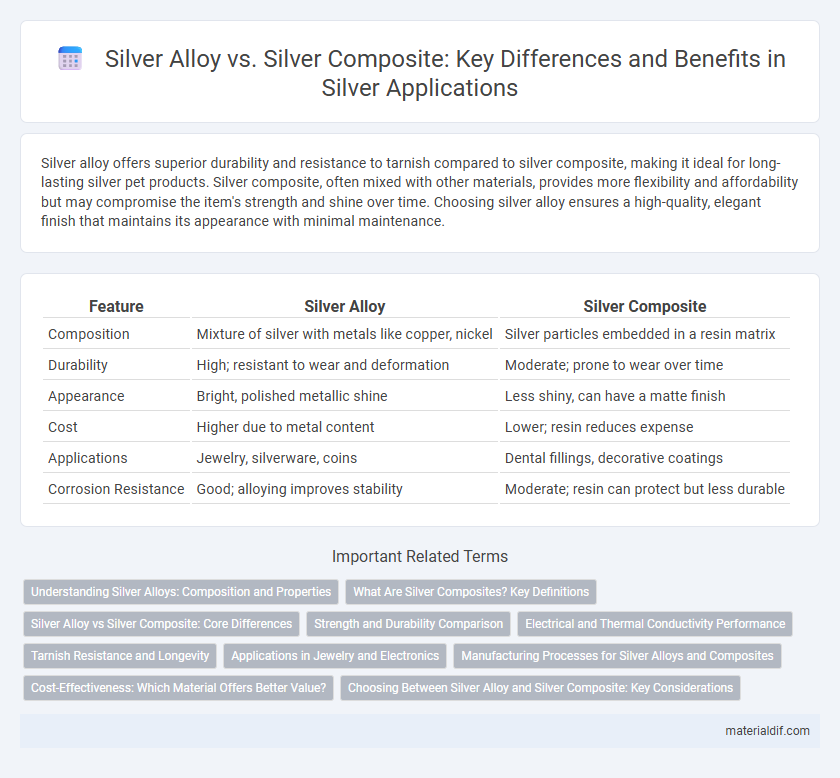

Table of Comparison

| Feature | Silver Alloy | Silver Composite |

|---|---|---|

| Composition | Mixture of silver with metals like copper, nickel | Silver particles embedded in a resin matrix |

| Durability | High; resistant to wear and deformation | Moderate; prone to wear over time |

| Appearance | Bright, polished metallic shine | Less shiny, can have a matte finish |

| Cost | Higher due to metal content | Lower; resin reduces expense |

| Applications | Jewelry, silverware, coins | Dental fillings, decorative coatings |

| Corrosion Resistance | Good; alloying improves stability | Moderate; resin can protect but less durable |

Understanding Silver Alloys: Composition and Properties

Silver alloys consist of pure silver combined with metals such as copper, zinc, or nickel to enhance strength, durability, and tarnish resistance. Common compositions include sterling silver, with 92.5% silver and 7.5% copper, valued for its balance of malleability and hardness. These alloys maintain high electrical and thermal conductivity while improving mechanical properties for industrial and jewelry applications.

What Are Silver Composites? Key Definitions

Silver composites are dental restorative materials combining silver particles with a resin matrix, designed to balance strength and aesthetics. Unlike traditional silver alloys, which are primarily metal-based, silver composites offer improved bonding to tooth structures and reduced corrosion. These materials are increasingly used in dentistry for fillings due to their enhanced durability and cosmetic appeal compared to pure silver alloys.

Silver Alloy vs Silver Composite: Core Differences

Silver alloy consists primarily of silver mixed with metals such as copper or zinc to enhance strength, durability, and tarnish resistance, making it ideal for jewelry and functional items. Silver composite materials combine silver particles with polymers or resins to create flexible, lightweight products often used in electronics and medical applications. The core difference lies in silver alloy's metallic nature providing structural integrity, whereas silver composites offer adaptability and specific property enhancements through polymer integration.

Strength and Durability Comparison

Silver alloy exhibits superior strength and durability compared to silver composite due to its metallic matrix reinforced with elements like copper or nickel, enhancing resistance to wear and deformation. Silver composite, often a blend of silver with non-metallic materials such as ceramics or polymers, generally offers lower tensile strength and is more prone to surface scratches and fractures under stress. For applications demanding high mechanical stability and longevity, silver alloys are the preferred choice over silver composites.

Electrical and Thermal Conductivity Performance

Silver alloy exhibits superior electrical and thermal conductivity compared to silver composite due to its higher purity and homogeneous metal structure. The presence of alloying elements in silver alloy slightly reduces conductivity but enhances mechanical strength, making it ideal for applications requiring efficient heat and electrical transfer. Silver composite typically contains non-metallic fillers that diminish conductivity but improve durability and wear resistance in less demanding conductive environments.

Tarnish Resistance and Longevity

Silver alloy typically offers superior tarnish resistance and longevity compared to silver composite materials due to its higher purity and stable metal composition. Tarnish resistance in silver alloys is enhanced by the presence of metals like copper and nickel, which create a durable surface less prone to oxidation. Silver composites, containing a mix of silver particles in resin or polymer matrices, tend to degrade faster and exhibit increased susceptibility to tarnishing and wear over time.

Applications in Jewelry and Electronics

Silver alloys, typically composed of 92.5% silver and 7.5% other metals like copper, provide enhanced durability and tarnish resistance, making them ideal for fine jewelry that requires both aesthetic appeal and long-lasting strength. Silver composites, which combine silver particles with polymer matrices, offer superior conductivity and corrosion resistance, making them highly suitable for advanced electronic applications such as conductive inks, sensors, and flexible circuits. Choosing between silver alloy and composite depends on the specific requirements of jewelry elegance versus electronic functionality and performance.

Manufacturing Processes for Silver Alloys and Composites

Silver alloys are produced by melting pure silver with other metals such as copper, nickel, or zinc, enhancing strength and durability through precise alloying ratios and controlled cooling techniques. Silver composites involve embedding silver particles into a matrix of other materials like polymers or ceramics, utilizing advanced processes like sintering or polymerization to achieve desired mechanical and aesthetic properties. Both manufacturing methods require stringent quality control to ensure homogeneity, optimal conductivity, and corrosion resistance tailored to specific industrial applications.

Cost-Effectiveness: Which Material Offers Better Value?

Silver alloys typically offer better cost-effectiveness compared to silver composites due to their enhanced durability and longevity, reducing the need for frequent replacements. Silver alloys maintain high silver content while incorporating metals like copper, which significantly lowers material and processing costs without compromising quality. In contrast, silver composites often involve more complex manufacturing and lower silver purity, making them less economical for long-term use.

Choosing Between Silver Alloy and Silver Composite: Key Considerations

Choosing between silver alloy and silver composite depends on factors such as durability, appearance, and cost-effectiveness. Silver alloys, often containing copper or zinc, offer enhanced strength and resistance to tarnishing, making them suitable for jewelry and functional items. Silver composites combine silver with other materials like resins or ceramics, providing greater design flexibility and lower price points but typically less durability than pure alloys.

Silver Alloy vs Silver Composite Infographic

materialdif.com

materialdif.com