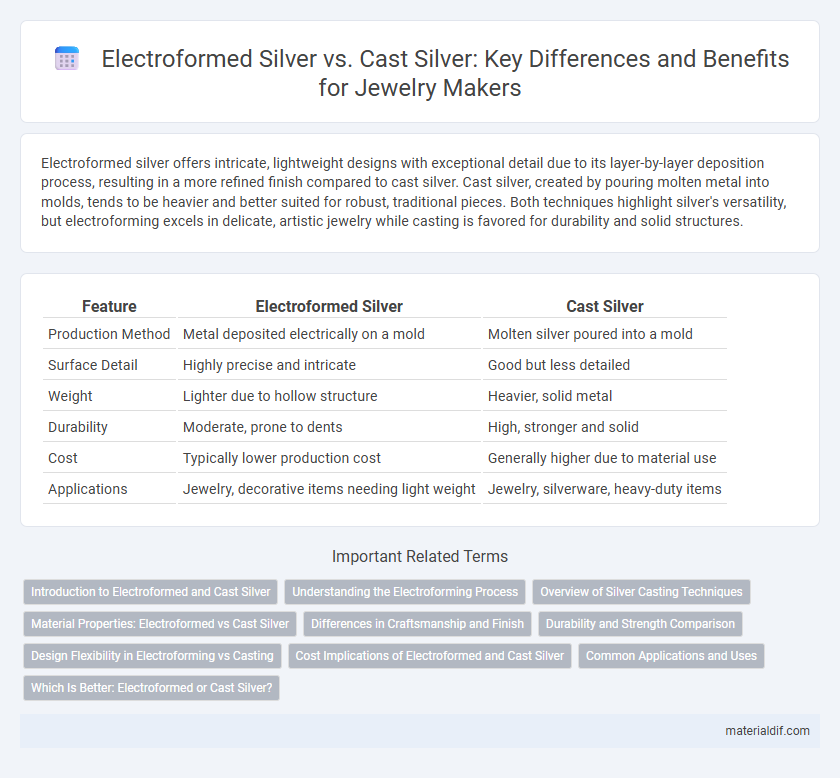

Electroformed silver offers intricate, lightweight designs with exceptional detail due to its layer-by-layer deposition process, resulting in a more refined finish compared to cast silver. Cast silver, created by pouring molten metal into molds, tends to be heavier and better suited for robust, traditional pieces. Both techniques highlight silver's versatility, but electroforming excels in delicate, artistic jewelry while casting is favored for durability and solid structures.

Table of Comparison

| Feature | Electroformed Silver | Cast Silver |

|---|---|---|

| Production Method | Metal deposited electrically on a mold | Molten silver poured into a mold |

| Surface Detail | Highly precise and intricate | Good but less detailed |

| Weight | Lighter due to hollow structure | Heavier, solid metal |

| Durability | Moderate, prone to dents | High, stronger and solid |

| Cost | Typically lower production cost | Generally higher due to material use |

| Applications | Jewelry, decorative items needing light weight | Jewelry, silverware, heavy-duty items |

Introduction to Electroformed and Cast Silver

Electroformed silver involves depositing silver ions onto a mold through an electrolytic process, creating a lightweight, hollow piece with intricate details and uniform thickness. Cast silver is produced by melting silver and pouring it into a mold, resulting in solid, dense pieces ideal for durability and traditional designs. Electroforming allows for complex shapes and thinner walls, while casting offers robust, heavier items with a classic silver finish.

Understanding the Electroforming Process

Electroforming silver involves depositing pure silver ions onto a conductive mold through an electrolytic bath, resulting in lightweight, hollow, and intricately detailed pieces. This technique allows for greater precision and thinner walls compared to cast silver, which is created by pouring molten metal into a mold and solidifying it, typically producing denser and heavier items. Understanding electroforming reveals its advantages in producing complex shapes with minimal material waste while maintaining a high level of surface detail.

Overview of Silver Casting Techniques

Electroformed silver offers precise detailing and lightweight properties by building layers of silver through electrochemical deposition, distinguishing it from cast silver which involves pouring molten metal into molds for shaping. Casting silver allows for mass production of complex shapes with consistent details, commonly used in traditional jewelry making and large-scale manufacturing. Both techniques provide unique advantages depending on design complexity and production volume, influencing the final texture and structural integrity of silver pieces.

Material Properties: Electroformed vs Cast Silver

Electroformed silver features a highly pure and dense microstructure due to the layer-by-layer deposition process, resulting in superior tensile strength and detailed surface finish compared to cast silver. Cast silver often contains minor inclusions and porosity from the melting process, which can reduce its mechanical strength and surface smoothness. The electroforming method allows for thinner, more precise designs with improved corrosion resistance, making it ideal for intricate applications where durability and detail are critical.

Differences in Craftsmanship and Finish

Electroformed silver involves building up layers of pure silver onto a mold through an electrochemical process, resulting in lightweight, hollow pieces with finely detailed surfaces and smooth finishes. Cast silver is created by pouring molten silver into a mold, producing solid, heavier items that often showcase intricate textures but may require more finishing work to remove casting imperfections. Craftsmanship in electroforming emphasizes precision and delicate detailing, while casting highlights durability and bold sculptural qualities.

Durability and Strength Comparison

Electroformed silver exhibits superior durability due to its uniform thickness and minimized internal stress, making it less prone to cracking or deformation compared to cast silver. Cast silver often contains microscopic porosity and variable grain structures, which can reduce its overall strength and increase susceptibility to wear over time. The controlled electroforming process results in a denser and more resilient silver layer, enhancing longevity in jewelry and functional applications.

Design Flexibility in Electroforming vs Casting

Electroformed silver offers superior design flexibility compared to cast silver, allowing for intricate, lightweight, and hollow structures that are difficult to achieve with traditional casting methods. The electroforming process builds up silver layer by layer over a detailed mandrel, enabling precise replication of fine details and complex shapes. In contrast, cast silver often faces limitations due to mold constraints and the risk of casting defects in delicate designs.

Cost Implications of Electroformed and Cast Silver

Electroformed silver typically incurs higher production costs due to the complex layering process and specialized equipment required, resulting in increased labor and energy expenses. Cast silver, using molds and molten metal, tends to be more cost-effective for mass production, reducing material waste and manufacturing time. These cost differences impact pricing strategies and product accessibility within the silver jewelry and collectible markets.

Common Applications and Uses

Electroformed silver is often used in delicate jewelry and intricate electronic components due to its precise layering and high purity, enabling fine detailing and enhanced conductivity. Cast silver is favored for larger, durable items such as sculptures, utensils, and jewelry with substantial volume, benefiting from its strength and ease of molding complex shapes. Both methods serve distinct roles in silver craftsmanship, with electroforming excelling in precision applications and casting dominating robust, everyday objects.

Which Is Better: Electroformed or Cast Silver?

Electroformed silver offers superior precision and intricate detailing due to its layer-by-layer deposition process, making it ideal for delicate, lightweight jewelry pieces. Cast silver, produced by melting and pouring molten silver into molds, provides greater durability and strength, suitable for more robust designs. Choosing between electroformed and cast silver depends on the desired balance of fine detail versus structural integrity in the final product.

Electroformed Silver vs Cast Silver Infographic

materialdif.com

materialdif.com