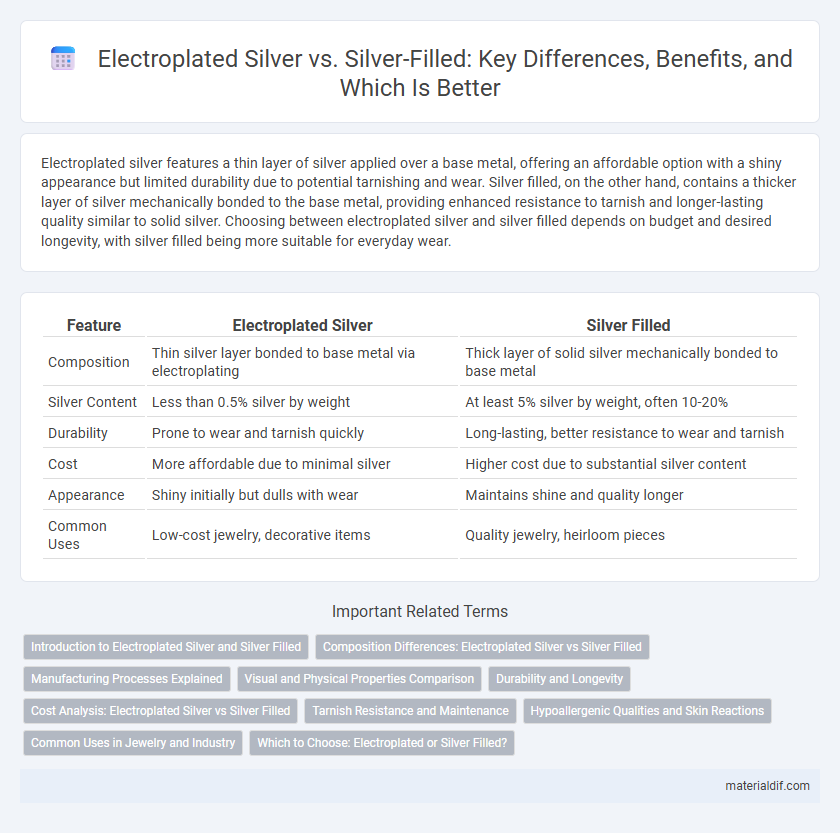

Electroplated silver features a thin layer of silver applied over a base metal, offering an affordable option with a shiny appearance but limited durability due to potential tarnishing and wear. Silver filled, on the other hand, contains a thicker layer of silver mechanically bonded to the base metal, providing enhanced resistance to tarnish and longer-lasting quality similar to solid silver. Choosing between electroplated silver and silver filled depends on budget and desired longevity, with silver filled being more suitable for everyday wear.

Table of Comparison

| Feature | Electroplated Silver | Silver Filled |

|---|---|---|

| Composition | Thin silver layer bonded to base metal via electroplating | Thick layer of solid silver mechanically bonded to base metal |

| Silver Content | Less than 0.5% silver by weight | At least 5% silver by weight, often 10-20% |

| Durability | Prone to wear and tarnish quickly | Long-lasting, better resistance to wear and tarnish |

| Cost | More affordable due to minimal silver | Higher cost due to substantial silver content |

| Appearance | Shiny initially but dulls with wear | Maintains shine and quality longer |

| Common Uses | Low-cost jewelry, decorative items | Quality jewelry, heirloom pieces |

Introduction to Electroplated Silver and Silver Filled

Electroplated silver jewelry features a thin layer of silver bonded to a base metal through an electrochemical process, offering a cost-effective way to achieve a silver finish. Silver-filled items consist of a much thicker layer of silver mechanically bonded to a core metal, ensuring greater durability and resistance to tarnish compared to electroplated pieces. The difference in silver content and manufacturing methods impacts the longevity, appearance, and price of these two popular silver jewelry types.

Composition Differences: Electroplated Silver vs Silver Filled

Electroplated silver consists of a thin layer of pure silver deposited onto a base metal, typically copper or brass, through an electrochemical process, resulting in a surface coating that can wear away over time. Silver-filled, however, contains a much thicker layer of silver mechanically bonded to a core metal, often comprising at least 5% silver by weight, offering greater durability and resistance to tarnish. The key compositional difference lies in the thickness and bonding of the silver layer, with silver-filled items maintaining a longer-lasting silver content compared to the ephemeral electroplated coating.

Manufacturing Processes Explained

Electroplated silver involves a base metal coated with a thin layer of pure silver through an electrochemical process, resulting in a durable yet affordable finish. Silver-filled products are made by mechanically bonding a thick layer of silver to a base metal core, offering greater longevity and resistance to wear compared to electroplated items. The manufacturing process of silver-filled items uses high heat and pressure to fuse the metals, whereas electroplating relies on electrical current to deposit silver atoms onto the surface.

Visual and Physical Properties Comparison

Electroplated silver features a thin layer of pure silver bonded to a base metal, offering a bright and shiny appearance that can tarnish quickly due to its delicate coating. Silver filled items contain a thick layer of silver mechanically bonded to a base, providing greater durability and resistance to wear while maintaining the look of solid silver. The visual quality of silver filled pieces remains consistent longer, and their physical properties include enhanced strength and reduced susceptibility to scratching compared to electroplated silver.

Durability and Longevity

Electroplated silver consists of a thin layer of silver bonded to a base metal, which wears off more quickly with frequent use, reducing its durability and longevity. Silver-filled items contain a much thicker layer of silver mechanically bonded to a base metal, offering enhanced resistance to tarnishing and wear, making them significantly more durable over time. The greater silver content in silver-filled jewelry ensures longer-lasting beauty and strength compared to electroplated pieces.

Cost Analysis: Electroplated Silver vs Silver Filled

Electroplated silver jewelry offers a lower initial cost due to a thin layer of silver coating over a base metal, making it more affordable but prone to wear and tarnish over time. Silver-filled items contain a thicker layer of solid silver bonded to a base metal, resulting in higher durability and a longer lifespan, which justifies the higher price. When comparing cost-effectiveness, silver-filled pieces provide better long-term value despite the upfront expense, while electroplated silver suits budget-conscious buyers seeking short-term use.

Tarnish Resistance and Maintenance

Electroplated silver features a thin layer of pure silver bonded to a base metal, which can wear away over time, leading to quicker tarnishing and requiring frequent polishing to maintain its shine. Silver-filled jewelry contains a much thicker layer of silver mechanically bonded to a core metal, offering significantly enhanced tarnish resistance and durability compared to electroplated silver. Maintenance for silver-filled pieces is easier and less frequent due to the thicker silver layer, making it a preferred choice for long-lasting, low-maintenance silver jewelry.

Hypoallergenic Qualities and Skin Reactions

Electroplated silver involves a thin layer of silver applied over a base metal, which can wear off and expose allergens, increasing the risk of skin reactions for sensitive individuals. Silver-filled jewelry contains a thick layer of pure silver bonded to a core metal, providing better durability and reducing the likelihood of irritation due to minimal exposure to base metals. Hypoallergenic qualities are superior in silver-filled pieces compared to electroplated silver, making them a safer choice for people with metal sensitivities.

Common Uses in Jewelry and Industry

Electroplated silver is commonly used in fashion jewelry and decorative items due to its affordability and shiny appearance, though the thin silver layer can wear off over time. Silver-filled material, which contains a thicker layer of silver bonded to a base metal, is preferred for higher-quality jewelry and industrial components requiring durability and better tarnish resistance. In industries such as electronics and medical tools, silver-filled parts offer superior conductivity and longevity compared to electroplated silver.

Which to Choose: Electroplated or Silver Filled?

Electroplated silver jewelry features a thin layer of silver coating a base metal, offering an affordable option with a shiny finish but less durability and susceptibility to tarnishing. Silver filled jewelry contains a thicker layer of solid silver mechanically bonded to a base metal, providing greater longevity, resistance to wear, and hypoallergenic properties. Choose silver filled for long-lasting, high-quality pieces, while electroplated silver suits budget-friendly fashion jewelry with moderate use.

Electroplated Silver vs Silver Filled Infographic

materialdif.com

materialdif.com