Hard silver solder offers stronger, more durable joints ideal for structural silver jewelry pieces, resisting high heat and mechanical stress better than soft silver solder. Soft silver solder melts at lower temperatures, making it suitable for delicate or intricate repairs where minimal heat exposure is essential to avoid damaging components. Choosing between hard and soft silver solder depends on the application's strength requirements and heat sensitivity.

Table of Comparison

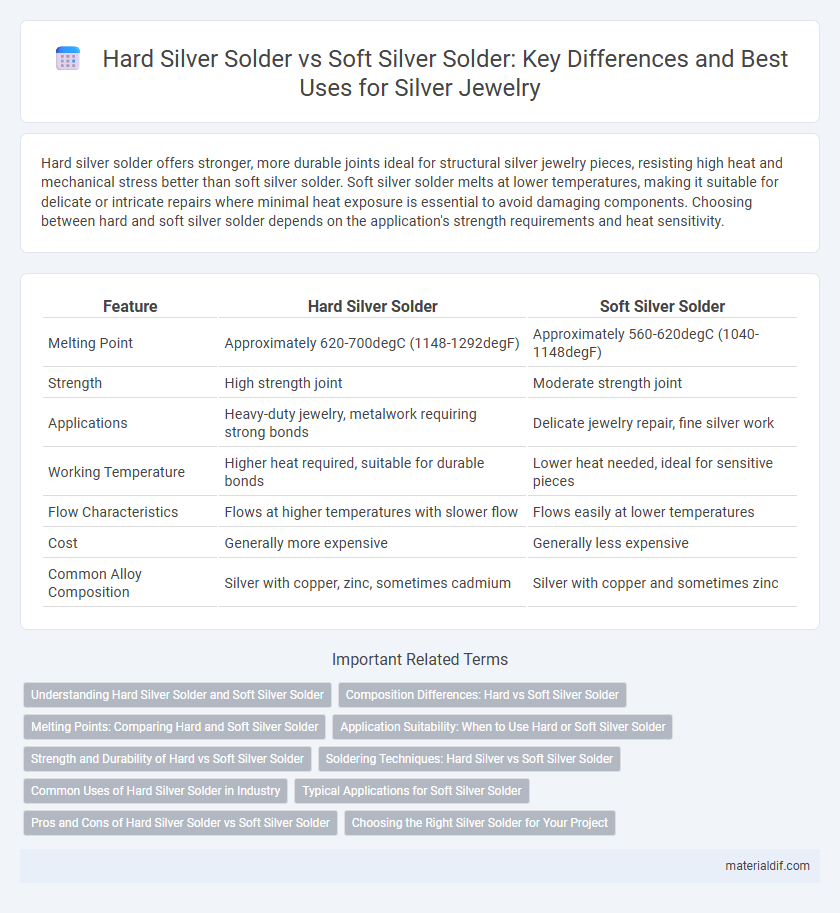

| Feature | Hard Silver Solder | Soft Silver Solder |

|---|---|---|

| Melting Point | Approximately 620-700degC (1148-1292degF) | Approximately 560-620degC (1040-1148degF) |

| Strength | High strength joint | Moderate strength joint |

| Applications | Heavy-duty jewelry, metalwork requiring strong bonds | Delicate jewelry repair, fine silver work |

| Working Temperature | Higher heat required, suitable for durable bonds | Lower heat needed, ideal for sensitive pieces |

| Flow Characteristics | Flows at higher temperatures with slower flow | Flows easily at lower temperatures |

| Cost | Generally more expensive | Generally less expensive |

| Common Alloy Composition | Silver with copper, zinc, sometimes cadmium | Silver with copper and sometimes zinc |

Understanding Hard Silver Solder and Soft Silver Solder

Hard silver solder and soft silver solder differ primarily in their melting points and applications within metalworking. Hard silver solder, with a melting point above 620degC, is ideal for joining thicker metals and creating strong, durable bonds in jewelry and silverware. Soft silver solder melts at lower temperatures, typically between 450degC and 550degC, making it suitable for delicate or intricate repairs where minimal heat is essential to avoid damage to the base metals.

Composition Differences: Hard vs Soft Silver Solder

Hard silver solder typically contains a higher percentage of silver, often ranging from 56% to 62%, combined with copper and zinc, resulting in a melting point between 620degC and 700degC. Soft silver solder generally has a lower silver content, around 40% to 45%, mixed with tin and zinc, which lowers its melting point to approximately 600degC to 630degC. The increased copper and silver content in hard solder provides greater joint strength and durability, while soft solder melts at lower temperatures suited for delicate or repair work.

Melting Points: Comparing Hard and Soft Silver Solder

Hard silver solder has a melting point typically between 620degC and 700degC, making it ideal for joinery requiring high heat resistance and strength. Soft silver solder melts at lower temperatures, around 560degC to 620degC, allowing for delicate or intricate work with minimal thermal stress to components. Selecting the appropriate solder melt point enhances joint durability and prevents damage during silverwork assembly.

Application Suitability: When to Use Hard or Soft Silver Solder

Hard silver solder, with a melting point typically above 620degC, is best suited for applications requiring high mechanical strength and durability, such as jewelry making, plumbing, and aerospace components. Soft silver solder, melting below 450degC, is ideal for delicate electronics and electrical connections where heat-sensitive materials are involved. Choosing between hard and soft silver solder depends on the thermal tolerance of the base metals and the structural demands of the final product.

Strength and Durability of Hard vs Soft Silver Solder

Hard silver solder offers superior strength and durability compared to soft silver solder, making it ideal for high-stress jewelry repairs and metalwork requiring robust joints. Its higher melting point ensures the bond withstands heat and mechanical wear without compromising the integrity of the connection. Soft silver solder, while easier to work with due to a lower melting temperature, forms weaker joints prone to failure under heavy strain or repeated thermal cycling.

Soldering Techniques: Hard Silver vs Soft Silver Solder

Hard silver solder requires higher temperatures, typically above 600degC, providing stronger, more durable joints ideal for structural metalwork and jewelry repair. Soft silver solder melts at lower temperatures around 450degC, suitable for delicate components and quicker, more precise applications such as electronics or fine jewelry assembly. Selecting the appropriate soldering technique depends on joint strength requirements, metal compatibility, and heat sensitivity of the materials involved.

Common Uses of Hard Silver Solder in Industry

Hard silver solder is predominantly used in industrial applications requiring strong, durable joints, such as in jewelry making, electronics, and plumbing. Its higher melting point compared to soft silver solder enables reliable connections in high-temperature environments and ensures mechanical stability. Industrial sectors favor hard silver solder for assembling metal components where structural integrity and resistance to thermal stress are critical.

Typical Applications for Soft Silver Solder

Soft silver solder is commonly used in electronics for joining delicate components due to its lower melting point, which prevents heat damage. It is ideal for plumbing and HVAC applications where creating leak-proof joints on copper and brass pipes is essential. The solder's fluidity and ease of use make it suitable for intricate jewelry repairs and assembling thin metal sheets.

Pros and Cons of Hard Silver Solder vs Soft Silver Solder

Hard silver solder offers stronger joint strength and higher melting points, making it ideal for heavy-duty applications and structural jewelry repairs. Soft silver solder melts at lower temperatures, reducing the risk of heat damage to delicate components but often results in weaker bonds that may not withstand stress. Choosing between hard and soft silver solder depends on the required durability and the thermal sensitivity of the materials being joined.

Choosing the Right Silver Solder for Your Project

Hard silver solder, typically containing higher silver content and melting above 600degC, provides stronger, more durable joints suitable for structural or high-stress jewelry projects. Soft silver solder melts at lower temperatures around 450-600degC, allowing for delicate work like fine detailing but resulting in less robust connections. Choosing the right silver solder depends on the project's mechanical requirements and heat sensitivity, with hard solder preferred for heavy-duty applications and soft solder ideal for intricate repairs or layering tasks.

Hard Silver Solder vs Soft Silver Solder Infographic

materialdif.com

materialdif.com