Soft silver is highly malleable and contains a higher percentage of pure silver, making it ideal for intricate jewelry designs and delicate silverware. Hard silver, often alloyed with metals like copper, offers increased durability and resistance to scratches, making it suitable for everyday items and functional pieces. Choosing between soft and hard silver depends on the desired balance between aesthetic detail and practical strength.

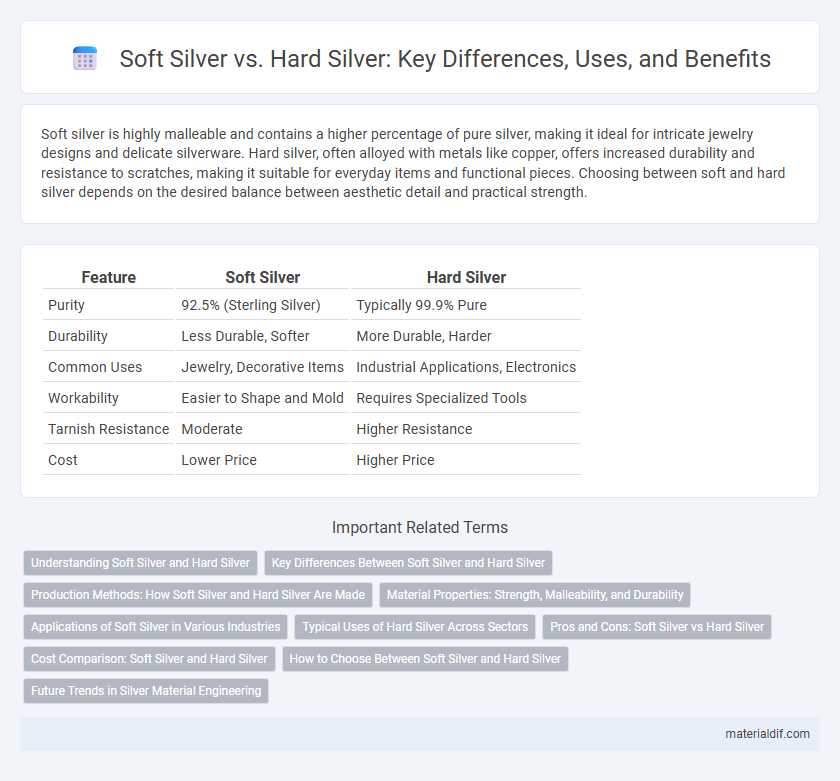

Table of Comparison

| Feature | Soft Silver | Hard Silver |

|---|---|---|

| Purity | 92.5% (Sterling Silver) | Typically 99.9% Pure |

| Durability | Less Durable, Softer | More Durable, Harder |

| Common Uses | Jewelry, Decorative Items | Industrial Applications, Electronics |

| Workability | Easier to Shape and Mold | Requires Specialized Tools |

| Tarnish Resistance | Moderate | Higher Resistance |

| Cost | Lower Price | Higher Price |

Understanding Soft Silver and Hard Silver

Soft silver, typically 99.9% pure, offers excellent electrical and thermal conductivity, making it ideal for high-precision applications like electronics and jewelry. Hard silver alloys, often mixed with copper or other metals, provide enhanced durability and strength, suitable for items requiring resistance to wear and deformation. Understanding the balance between purity and alloying elements is crucial for choosing the right silver type depending on the intended use.

Key Differences Between Soft Silver and Hard Silver

Soft silver typically contains a higher purity level, often above 99.9%, making it more malleable and ideal for detailed jewelry work and intricate designs. Hard silver, alloyed with metals such as copper, exhibits increased durability and resistance to scratching, making it suitable for functional items like utensils and coins. The key differences lie in their purity, mechanical properties, and application suitability.

Production Methods: How Soft Silver and Hard Silver Are Made

Soft silver is primarily produced through processes such as casting and annealing, where the metal is melted and gradually cooled to enhance its ductility and malleability. Hard silver involves alloying pure silver with metals like copper and employing techniques like cold working or work hardening to increase its strength and durability. These distinct production methods result in soft silver being ideal for intricate crafting, while hard silver suits applications requiring greater resistance to wear.

Material Properties: Strength, Malleability, and Durability

Soft silver, primarily composed of nearly pure silver (99.9%), exhibits high malleability and excellent ductility, making it ideal for intricate jewelry and detailed engraving. Hard silver, often alloyed with metals like copper or nickel, offers enhanced strength and durability, suitable for items requiring resistance to wear and deformation. The trade-off involves reduced malleability in hard silver but significantly improved hardness, extending the lifespan of functional silver products such as flatware and coins.

Applications of Soft Silver in Various Industries

Soft silver, characterized by its high malleability and excellent electrical conductivity, is widely used in the electronics industry for manufacturing electrical contacts, connectors, and conductive coatings. In the jewelry sector, its softness allows for intricate designs and detailed engraving, while its antimicrobial properties make it suitable for medical applications such as wound dressings and surgical instruments. The chemical industry employs soft silver due to its resistance to corrosion and catalytic capabilities in processes like ethylene oxide production.

Typical Uses of Hard Silver Across Sectors

Hard silver is commonly utilized in jewelry making due to its enhanced durability and resistance to scratching compared to soft silver. In the electronics industry, hard silver plating improves conductivity and wear resistance for connectors and contacts. Additionally, hard silver is favored in coin production and tableware, where strength and longevity are essential.

Pros and Cons: Soft Silver vs Hard Silver

Soft silver offers superior malleability and ease of shaping, making it ideal for intricate jewelry designs and detailed craftsmanship. Hard silver provides increased durability and scratch resistance, suitable for items requiring long-term wear and structural integrity. While soft silver is prone to deformation and requires frequent polishing, hard silver sacrifices some flexibility but ensures enhanced strength and longevity.

Cost Comparison: Soft Silver and Hard Silver

Soft silver generally costs less than hard silver due to its higher purity, typically 99.9% silver, which is easier to refine and process. Hard silver contains additional alloying metals like copper or nickel, increasing its durability but also the production expenses, resulting in higher pricing. The choice between soft silver and hard silver often balances budget considerations with the specific needs for strength and wear resistance in applications.

How to Choose Between Soft Silver and Hard Silver

Choosing between soft silver and hard silver depends on the intended use and desired durability; soft silver, with its higher purity (99.9% silver), offers excellent malleability and a brilliant finish ideal for fine jewelry and intricate designs. Hard silver, alloyed with metals like copper to increase hardness and strength, provides better scratch resistance and is suitable for everyday items such as silverware and coins. Evaluate factors like wear resistance, design complexity, and the balance between purity and toughness to select the best silver type for your specific needs.

Future Trends in Silver Material Engineering

Future trends in silver material engineering emphasize enhancing durability and performance, driving innovations in hard silver alloys with improved corrosion resistance and mechanical strength. Soft silver remains crucial for applications requiring high conductivity and malleability, but emerging hybrid composites aim to bridge softness with enhanced wear resistance. Advancements in nanostructuring and surface treatments are poised to revolutionize silver materials, optimizing their use in electronics, catalysts, and medical devices.

Soft Silver vs Hard Silver Infographic

materialdif.com

materialdif.com