Silk noil is made from short fibers left over after filament silk is reeled, resulting in a textured, matte fabric that is more affordable and less lustrous. Filament silk consists of long continuous fibers that produce a smooth, shiny, and stronger fabric, prized for luxury garments and high-end textiles. Choosing between silk noil and filament silk depends on the desired texture, appearance, and budget for the final product.

Table of Comparison

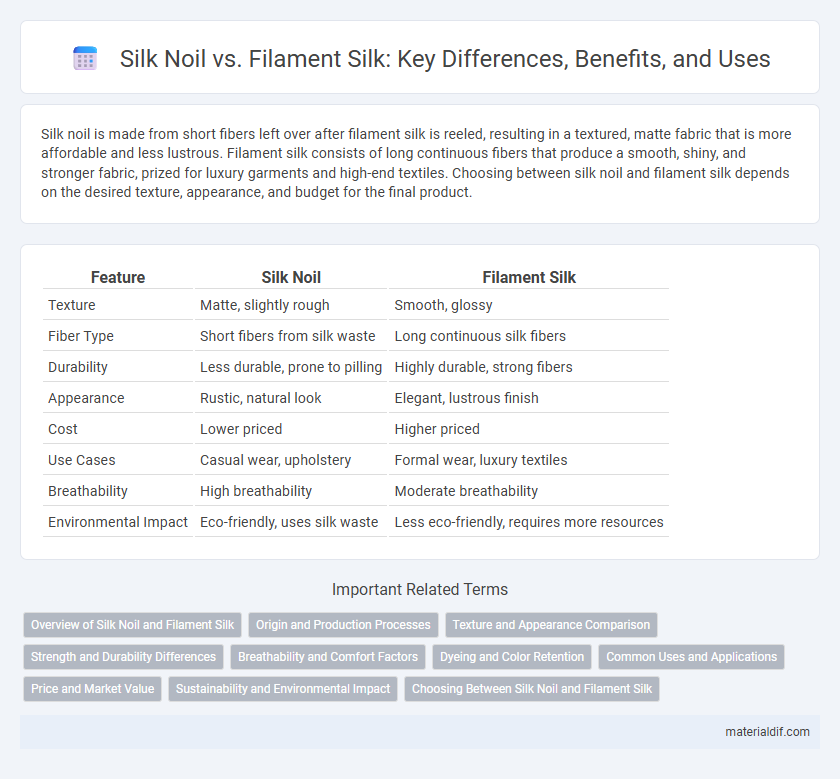

| Feature | Silk Noil | Filament Silk |

|---|---|---|

| Texture | Matte, slightly rough | Smooth, glossy |

| Fiber Type | Short fibers from silk waste | Long continuous silk fibers |

| Durability | Less durable, prone to pilling | Highly durable, strong fibers |

| Appearance | Rustic, natural look | Elegant, lustrous finish |

| Cost | Lower priced | Higher priced |

| Use Cases | Casual wear, upholstery | Formal wear, luxury textiles |

| Breathability | High breathability | Moderate breathability |

| Environmental Impact | Eco-friendly, uses silk waste | Less eco-friendly, requires more resources |

Overview of Silk Noil and Filament Silk

Silk noil, derived from shorter silk fibers left after filament silk extraction, offers a textured, matte finish commonly used in upholstery and casual wear, providing a cost-effective and durable alternative. Filament silk consists of long, continuous fibers harvested directly from silkworm cocoons, prized for its smooth, lustrous appearance and high tensile strength, making it ideal for luxury clothing and fine textiles. Both types of silk contribute unique qualities to fabric production, balancing affordability and elegance in different applications.

Origin and Production Processes

Silk noil originates from the shorter fibers left over after filament silk extraction, often sourced from wild or domesticated silkworms that produce irregular cocoons. The production process of silk noil involves spinning these shorter fibers into yarn, resulting in a textured fabric with a matte finish and a slightly coarse feel. Filament silk is derived from the long, continuous fibers of intact silkworm cocoons, primarily from the Bombyx mori species, produced through careful reeling that preserves the fiber's strength and smoothness.

Texture and Appearance Comparison

Silk noil has a rougher texture and matte appearance due to the shorter fibers left after silk filament extraction, giving it a nubby, uneven surface ideal for casual or rustic fabrics. Filament silk, composed of long continuous fibers, boasts a smooth, lustrous texture and a shiny, sleek appearance perfect for formal and luxurious garments. The contrast in fiber length results in silk noil being more breathable and textured, while filament silk offers a delicate, glossy finish.

Strength and Durability Differences

Silk noil, made from shorter fibers and sericin residue, is less strong and durable compared to filament silk, which consists of long, continuous fibers. Filament silk exhibits superior tensile strength, making it more resistant to wear, tearing, and stretching during use. The structural integrity of filament silk fibers ensures prolonged longevity in textiles, whereas silk noil tends to degrade faster under mechanical stress.

Breathability and Comfort Factors

Silk noil, made from shorter silk fibers, offers enhanced breathability due to its slightly porous texture, allowing better air circulation and moisture absorption which improves comfort in warm climates. Filament silk, composed of long continuous fibers, provides a smoother, more luxurious feel but tends to trap heat slightly more due to its dense, tightly woven structure. The choice between silk noil and filament silk significantly affects garment comfort, with silk noil favored for casual, breathable wear and filament silk preferred for elegant, smooth finishes.

Dyeing and Color Retention

Silk noil absorbs dye more readily due to its rough, uneven texture, resulting in vibrant, matte finishes with enhanced color depth. Filament silk, with its smooth and continuous fibers, offers a glossy sheen but can sometimes resist deep dye penetration, making color retention reliant on high-quality dyeing techniques. Both silk types require careful dye selection to maximize colorfastness, but silk noil generally demonstrates superior dye uptake and longer-lasting color vibrancy.

Common Uses and Applications

Silk noil, derived from shorter fibers left after filament silk extraction, is commonly used in upholstery, home decor, and casual apparel due to its textured, matte finish and affordability. Filament silk, composed of long, continuous fibers, is favored for luxury garments, high-end fashion, and fine bedding, offering a smooth, lustrous surface and superior strength. Both types serve distinct markets, with silk noil often utilized in rustic or vintage-inspired designs while filament silk caters to premium, elegant applications.

Price and Market Value

Silk noil is significantly more affordable than filament silk due to its shorter fibers and less uniform texture, making it highly favored in budget-conscious markets. Filament silk, prized for its smoothness and durability, commands a higher price and holds greater market value in luxury textile segments. The price disparity reflects differences in production complexity and end-use applications, with filament silk dominating premium apparel and silk noil appealing to eco-friendly and artisanal product niches.

Sustainability and Environmental Impact

Silk noil, derived from the shorter fibers left after combing filament silk, offers a more sustainable alternative by utilizing what is traditionally considered waste, reducing raw material consumption and minimizing environmental impact. Filament silk production often requires intensive water and energy usage, whereas silk noil processing generally involves less resource consumption and lower chemical treatments, contributing to its eco-friendliness. Both types have environmental footprints, but silk noil's upcycling of silk remnants positions it as a preferable choice in sustainable textile manufacturing.

Choosing Between Silk Noil and Filament Silk

Silk noil, sourced from shorter fibers leftover after filament silk extraction, offers a matte finish, increased durability, and a textured, natural aesthetic ideal for casual wear or home decor. Filament silk, composed of long, continuous fibers, provides a smooth, lustrous surface with superior strength and elegance suitable for formal garments and luxury textiles. Choosing between silk noil and filament silk depends on desired texture, durability, and end-use, balancing affordability with the refined appearance of filament silk or the rustic charm and practicality of silk noil.

Silk noil vs Filament silk Infographic

materialdif.com

materialdif.com