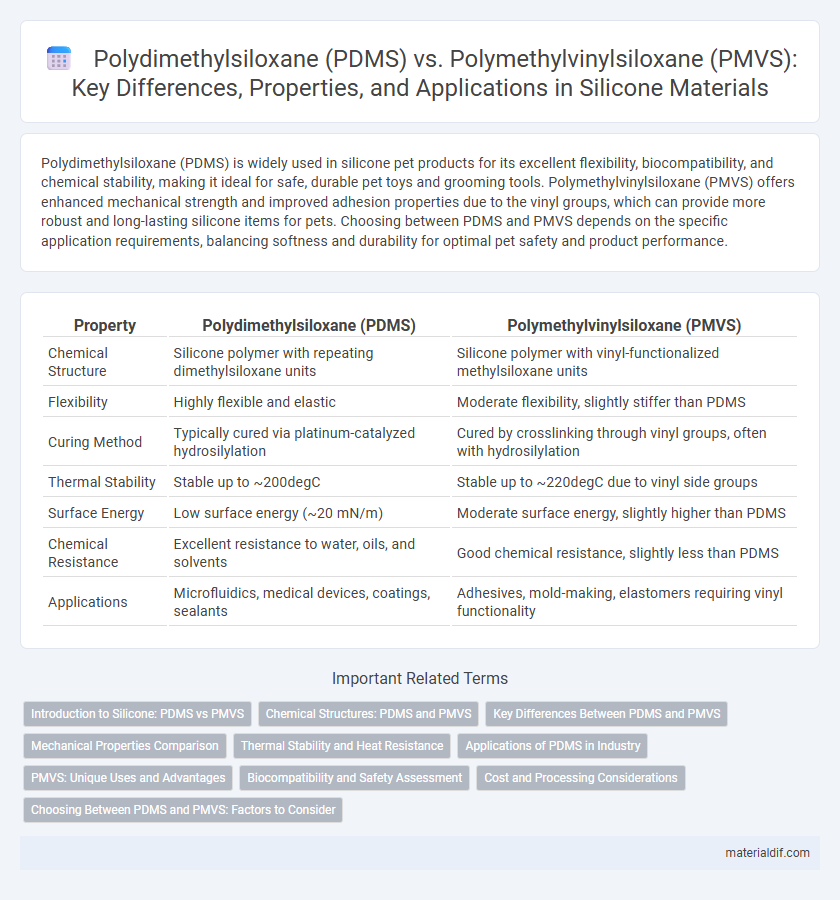

Polydimethylsiloxane (PDMS) is widely used in silicone pet products for its excellent flexibility, biocompatibility, and chemical stability, making it ideal for safe, durable pet toys and grooming tools. Polymethylvinylsiloxane (PMVS) offers enhanced mechanical strength and improved adhesion properties due to the vinyl groups, which can provide more robust and long-lasting silicone items for pets. Choosing between PDMS and PMVS depends on the specific application requirements, balancing softness and durability for optimal pet safety and product performance.

Table of Comparison

| Property | Polydimethylsiloxane (PDMS) | Polymethylvinylsiloxane (PMVS) |

|---|---|---|

| Chemical Structure | Silicone polymer with repeating dimethylsiloxane units | Silicone polymer with vinyl-functionalized methylsiloxane units |

| Flexibility | Highly flexible and elastic | Moderate flexibility, slightly stiffer than PDMS |

| Curing Method | Typically cured via platinum-catalyzed hydrosilylation | Cured by crosslinking through vinyl groups, often with hydrosilylation |

| Thermal Stability | Stable up to ~200degC | Stable up to ~220degC due to vinyl side groups |

| Surface Energy | Low surface energy (~20 mN/m) | Moderate surface energy, slightly higher than PDMS |

| Chemical Resistance | Excellent resistance to water, oils, and solvents | Good chemical resistance, slightly less than PDMS |

| Applications | Microfluidics, medical devices, coatings, sealants | Adhesives, mold-making, elastomers requiring vinyl functionality |

Introduction to Silicone: PDMS vs PMVS

Polydimethylsiloxane (PDMS) and Polymethylvinylsiloxane (PMVS) are widely used silicones with distinct chemical structures influencing their applications. PDMS, characterized by its flexible Si-O backbone and methyl side groups, offers excellent thermal stability, flexibility, and hydrophobicity, making it ideal for sealants, lubricants, and medical devices. In contrast, PMVS incorporates vinyl groups that enable cross-linking and functionalization, enhancing its suitability for adhesives, coatings, and customized elastomers in advanced materials science.

Chemical Structures: PDMS and PMVS

Polydimethylsiloxane (PDMS) features a repeating siloxane backbone with two methyl groups attached to each silicon atom, providing hydrophobicity and flexibility. Polymethylvinylsiloxane (PMVS) differs by having one methyl and one vinyl group per silicon atom, enabling cross-linking through the vinyl sites for enhanced mechanical properties. The vinyl functional groups in PMVS introduce chemical reactivity absent in the fully methyl-substituted PDMS structure.

Key Differences Between PDMS and PMVS

Polydimethylsiloxane (PDMS) is a silicone polymer characterized by its flexible, hydrophobic methyl side groups, making it widely used for medical devices and lubricants due to its biocompatibility and thermal stability. Polymethylvinylsiloxane (PMVS), in contrast, contains vinyl groups that enable cross-linking reactions, enhancing its elasticity and making it ideal for dental impression materials and molding applications. The key differences lie in PDMS's inert, flexible structure versus PMVS's functionalized vinyl groups that allow curing and improved mechanical properties.

Mechanical Properties Comparison

Polydimethylsiloxane (PDMS) exhibits excellent flexibility and elasticity with a low Young's modulus typically around 750 kPa, making it highly suitable for applications requiring soft, stretchable materials. Polymethylvinylsiloxane (PMVS) generally demonstrates higher mechanical strength and improved tensile resistance due to the incorporation of vinyl groups, resulting in a greater modulus and enhanced durability under mechanical stress. The increased crosslink density and vinyl functionalization in PMVS enable superior hardness and abrasion resistance compared to PDMS, which is often valued for its biocompatibility and optical clarity but lower mechanical toughness.

Thermal Stability and Heat Resistance

Polydimethylsiloxane (PDMS) exhibits excellent thermal stability with a decomposition temperature around 300degC, making it ideal for applications requiring prolonged heat exposure. Polymethylvinylsiloxane (PMVS) offers enhanced heat resistance due to the vinyl groups that allow cross-linking, improving its thermal durability beyond that of PDMS. The vinyl functionality in PMVS promotes stronger network formation, resulting in higher resistance to thermal degradation under elevated temperatures.

Applications of PDMS in Industry

Polydimethylsiloxane (PDMS) is extensively used in industries such as electronics for encapsulation and insulation due to its excellent dielectric properties and thermal stability. Its applications extend to cosmetics, where PDMS functions as a conditioning agent and emollient, and in the medical field for manufacturing flexible implants and wound dressings because of its biocompatibility. Compared to Polymethylvinylsiloxane (PMVS), PDMS offers superior chemical inertness and mechanical flexibility, making it the preferred choice for diverse industrial applications requiring durability and performance.

PMVS: Unique Uses and Advantages

Polymethylvinylsiloxane (PMVS) offers unique advantages in applications requiring enhanced flexibility and improved chemical resistance compared to Polydimethylsiloxane (PDMS), making it ideal for use in coatings, adhesives, and sealants. Its vinyl groups enable superior crosslinking capabilities, resulting in tougher and more durable silicone materials with elevated thermal stability. PMVS's ability to maintain mechanical integrity under harsh conditions broadens its applicability in advanced electronics, medical devices, and automotive industries.

Biocompatibility and Safety Assessment

Polydimethylsiloxane (PDMS) is widely recognized for its excellent biocompatibility, being inert, non-toxic, and extensively used in medical implants and devices. Polymethylvinylsiloxane (PMVS) exhibits similar biocompatibility profiles but with enhanced mechanical properties due to vinyl functional groups, making it suitable for applications requiring greater flexibility and durability. Safety assessments of both materials indicate minimal cytotoxicity and immunogenic responses, with validated use in biomedical devices, although PDMS remains the gold standard for long-term implantable applications.

Cost and Processing Considerations

Polydimethylsiloxane (PDMS) is generally more cost-effective than Polymethylvinylsiloxane (PMVS) due to its widespread availability and simpler synthesis process. PDMS offers easier handling and faster curing times in processing, making it suitable for large-scale applications. In contrast, PMVS requires more specialized catalysts and precise curing conditions, increasing production costs and complexity.

Choosing Between PDMS and PMVS: Factors to Consider

Choosing between Polydimethylsiloxane (PDMS) and Polymethylvinylsiloxane (PMVS) hinges on application-specific requirements such as flexibility, chemical resistance, and curing properties. PDMS is renowned for its excellent thermal stability and biocompatibility, making it ideal for medical devices and electronics, whereas PMVS offers superior adhesion and faster curing times suitable for coatings and adhesives. Evaluating factors like mechanical strength, environmental exposure, and curing conditions ensures optimal material selection for performance and durability.

Polydimethylsiloxane (PDMS) vs Polymethylvinylsiloxane (PMVS) Infographic

materialdif.com

materialdif.com