Platinum cure silicone offers superior purity and flexibility, making it ideal for detailed pet mold making and safe for prolonged animal contact. Peroxide cure silicone provides a more affordable alternative with faster curing times but may release slight odors and exhibit reduced durability. Choosing between platinum and peroxide cure silicones depends on balancing budget constraints with the desired quality and safety for pet-related applications.

Table of Comparison

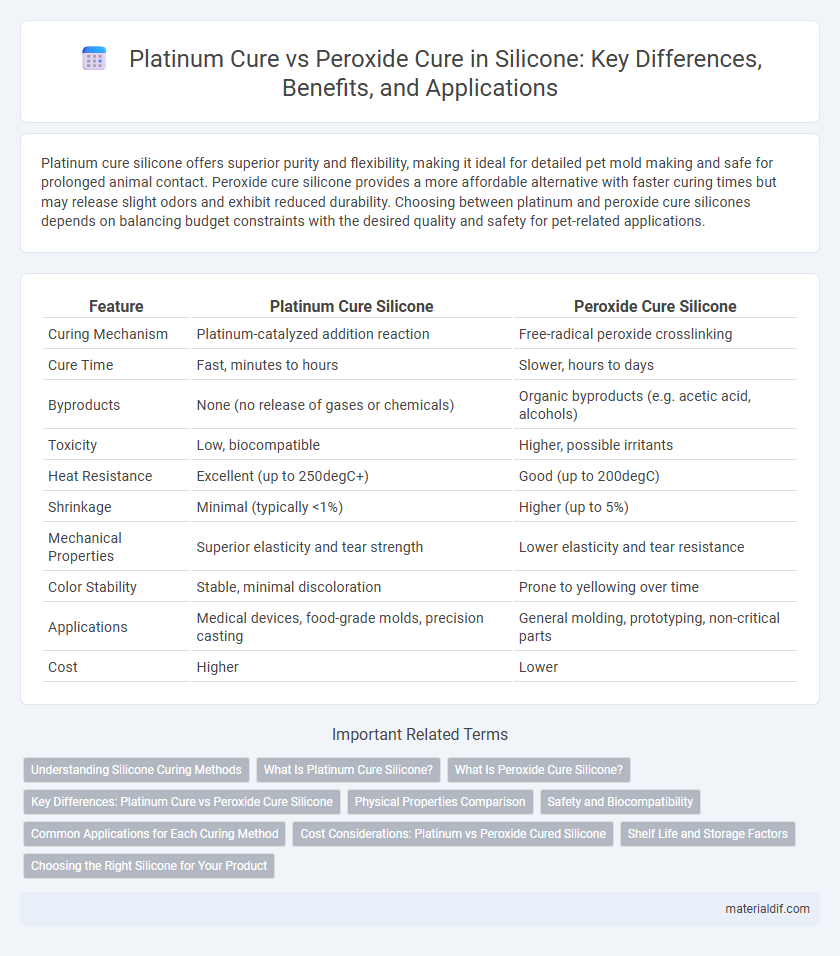

| Feature | Platinum Cure Silicone | Peroxide Cure Silicone |

|---|---|---|

| Curing Mechanism | Platinum-catalyzed addition reaction | Free-radical peroxide crosslinking |

| Cure Time | Fast, minutes to hours | Slower, hours to days |

| Byproducts | None (no release of gases or chemicals) | Organic byproducts (e.g. acetic acid, alcohols) |

| Toxicity | Low, biocompatible | Higher, possible irritants |

| Heat Resistance | Excellent (up to 250degC+) | Good (up to 200degC) |

| Shrinkage | Minimal (typically <1%) | Higher (up to 5%) |

| Mechanical Properties | Superior elasticity and tear strength | Lower elasticity and tear resistance |

| Color Stability | Stable, minimal discoloration | Prone to yellowing over time |

| Applications | Medical devices, food-grade molds, precision casting | General molding, prototyping, non-critical parts |

| Cost | Higher | Lower |

Understanding Silicone Curing Methods

Platinum cure silicone offers superior biocompatibility and low shrinkage, making it ideal for medical and electronic applications, while peroxide cure silicone provides greater flexibility in coloration and lower raw material costs. Understanding these curing methods involves assessing factors such as cure kinetics, byproduct formation, and mechanical properties to select the optimal system for specific industrial uses. The choice between platinum and peroxide cure impacts durability, elasticity, and chemical resistance of the final silicone product.

What Is Platinum Cure Silicone?

Platinum cure silicone is a high-purity elastomer known for its superior biocompatibility, flexibility, and chemical resistance, commonly used in medical devices and food-grade applications. It cures via a platinum-catalyzed addition reaction, resulting in minimal shrinkage and excellent dimensional stability compared to peroxide-cure silicones, which rely on a free radical mechanism producing by-products that can affect mechanical properties. The platinum-cure process ensures a more inert, durable silicone ideal for precision molding and applications requiring consistent performance over time.

What Is Peroxide Cure Silicone?

Peroxide cure silicone is a type of silicone elastomer that vulcanizes through a chemical reaction initiated by organic peroxides, resulting in a cross-linked polymer network. Unlike platinum cure silicone, peroxide cure silicone is more resistant to inhibitors such as sulfur and amines, making it suitable for applications with complex substrates. This curing method offers excellent heat resistance and mechanical properties but may release volatile byproducts during the curing process.

Key Differences: Platinum Cure vs Peroxide Cure Silicone

Platinum cure silicone offers superior biocompatibility and faster curing times compared to peroxide cure silicone, which relies on chemical cross-linking agents and may leave residues. Platinum cure systems produce cleaner, more precise molds ideal for medical and food-grade applications, while peroxide cure silicones are generally more cost-effective but less durable and prone to shrinkage. The choice between platinum and peroxide cure silicone largely depends on application requirements for toxicity, elasticity, and environmental resistance.

Physical Properties Comparison

Platinum cure silicone offers superior tensile strength and elongation compared to peroxide cure silicone, resulting in more durable and flexible final products. The platinum cure process produces minimal shrinkage and higher tear resistance, enhancing the physical integrity of molds and elastomers. Peroxide cure silicone may exhibit faster curing times but often sacrifices elasticity and long-term mechanical stability, making it less suitable for applications requiring high performance.

Safety and Biocompatibility

Platinum cure silicone offers superior biocompatibility and safety compared to peroxide cure silicone, as it contains no hazardous by-products or residuals that can cause skin irritation or allergic reactions. The platinum catalyst enables a stable, non-toxic curing process, making it ideal for medical devices, prosthetics, and food-contact applications. In contrast, peroxide-cured silicone may release volatile organic compounds and residual peroxide, increasing the risk of cytotoxicity and limiting its suitability for sensitive or long-term skin contact.

Common Applications for Each Curing Method

Platinum cure silicone is widely used in medical devices, food-grade applications, and high-precision molds due to its purity and low shrinkage properties. Peroxide cure silicone is commonly found in industrial seals, automotive parts, and household goods where slightly higher shrinkage and odors are acceptable. Each curing method offers distinct advantages aligning with specific industry requirements and performance standards.

Cost Considerations: Platinum vs Peroxide Cured Silicone

Platinum-cured silicone typically incurs higher upfront costs due to the expensive platinum catalyst, but it offers superior durability and biocompatibility, justifying long-term investment in medical and food-grade applications. Peroxide-cured silicone has a lower material cost and faster curing times, making it more economical for general-purpose industrial products where extreme precision is less critical. Evaluating total lifecycle expenses, including processing, waste, and product reliability, helps determine the most cost-effective choice between platinum and peroxide cure methods.

Shelf Life and Storage Factors

Platinum cure silicone exhibits a longer shelf life, typically up to 12 months, due to its stable platinum catalyst that resists degradation when stored in airtight, cool environments. Peroxide cure silicone generally has a shorter shelf life of 6 to 9 months, as peroxide compounds can decompose over time, especially when exposed to heat or moisture. Proper storage conditions, including low humidity and temperature control, significantly influence the durability and performance stability of both silicone types.

Choosing the Right Silicone for Your Product

Platinum cure silicone offers superior durability, excellent tear resistance, and high purity, making it ideal for medical, food-grade, and electronic applications requiring biocompatibility and minimal shrinkage. Peroxide cure silicone provides cost-effectiveness and faster curing times, suited for general industrial use where slight odor and lower tear strength are acceptable. Selecting the right silicone depends on product requirements like mechanical properties, chemical resistance, and end-use environment for optimal performance and longevity.

Platinum Cure vs Peroxide Cure Infographic

materialdif.com

materialdif.com