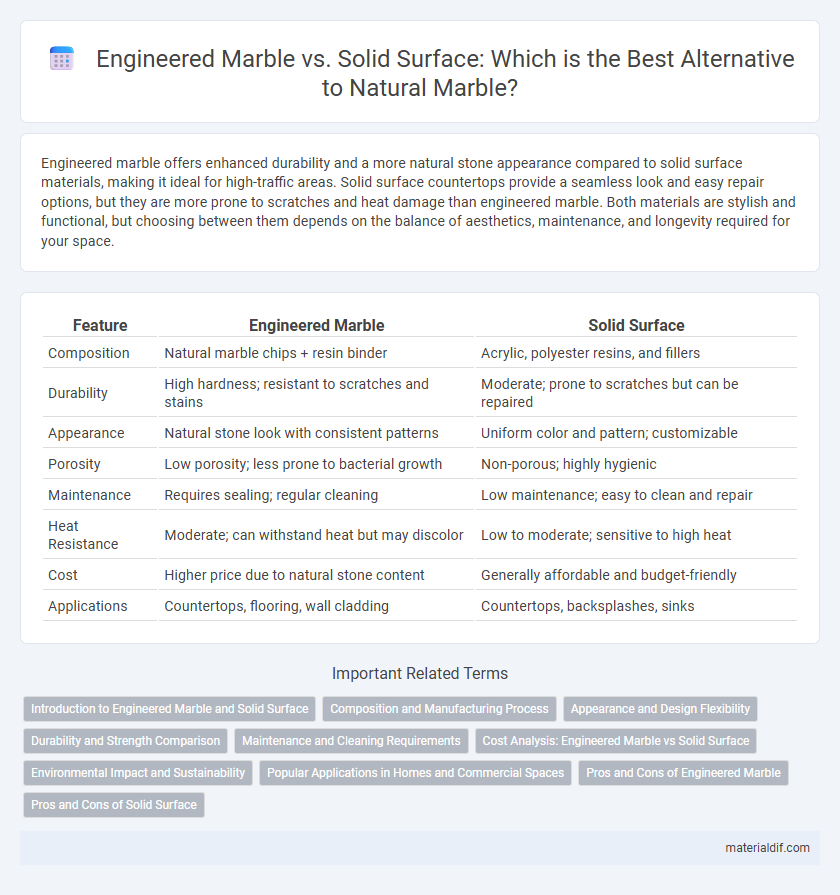

Engineered marble offers enhanced durability and a more natural stone appearance compared to solid surface materials, making it ideal for high-traffic areas. Solid surface countertops provide a seamless look and easy repair options, but they are more prone to scratches and heat damage than engineered marble. Both materials are stylish and functional, but choosing between them depends on the balance of aesthetics, maintenance, and longevity required for your space.

Table of Comparison

| Feature | Engineered Marble | Solid Surface |

|---|---|---|

| Composition | Natural marble chips + resin binder | Acrylic, polyester resins, and fillers |

| Durability | High hardness; resistant to scratches and stains | Moderate; prone to scratches but can be repaired |

| Appearance | Natural stone look with consistent patterns | Uniform color and pattern; customizable |

| Porosity | Low porosity; less prone to bacterial growth | Non-porous; highly hygienic |

| Maintenance | Requires sealing; regular cleaning | Low maintenance; easy to clean and repair |

| Heat Resistance | Moderate; can withstand heat but may discolor | Low to moderate; sensitive to high heat |

| Cost | Higher price due to natural stone content | Generally affordable and budget-friendly |

| Applications | Countertops, flooring, wall cladding | Countertops, backsplashes, sinks |

Introduction to Engineered Marble and Solid Surface

Engineered marble combines natural marble powder with resins to create a durable, non-porous surface ideal for countertops and flooring. Solid surfaces are man-made materials composed of acrylic, polyester, or a combination, offering seamless installation and resistance to stains and scratches. Both materials provide aesthetic versatility and enhanced durability compared to natural marble, making them popular choices in modern interior design.

Composition and Manufacturing Process

Engineered marble consists of natural marble dust combined with resin and pigments, resulting in a durable and versatile surface through a casting or molding process. Solid surface materials are primarily composed of acrylic, polyester, or a blend of both, mixed with alumina trihydrate, manufactured by pouring or casting the mixture into sheets. The manufacturing of engineered marble emphasizes replicating natural stone aesthetics, while solid surface production enables seamless joints and customizable designs.

Appearance and Design Flexibility

Engineered marble offers a natural stone appearance with consistent patterns and a polished finish, while solid surface materials provide a uniform look that can mimic various stone textures. Engineered marble is limited by its stone composition, restricting customization, whereas solid surfaces allow extensive design flexibility with seamless integration of colors, shapes, and embedded patterns. This makes solid surfaces ideal for innovative designs and complex installations, whereas engineered marble excels in replicating traditional stone aesthetics.

Durability and Strength Comparison

Engineered marble offers superior durability due to its composition of crushed natural marble bonded with resins, making it highly resistant to impact, scratches, and heat compared to solid surface materials like acrylic or polyester composites. Solid surface countertops, while non-porous and easy to maintain, generally lack the hardness and strength of engineered marble, leading to more susceptibility to dents and surface damage over time. For applications requiring long-lasting strength and resistance to wear, engineered marble provides a more robust and resilient option than solid surface alternatives.

Maintenance and Cleaning Requirements

Engineered marble requires minimal maintenance due to its non-porous surface, resisting stains and scratches more effectively than solid surface materials. Solid surface countertops need regular sealing and gentle cleaning with non-abrasive products to prevent discoloration and damage. Both materials benefit from immediate spill cleanup, but engineered marble offers greater durability and ease of upkeep in high-traffic areas.

Cost Analysis: Engineered Marble vs Solid Surface

Engineered marble typically costs between $50 and $100 per square foot, offering a durable and aesthetically pleasing option at a moderate price point. Solid surface materials range from $35 to $85 per square foot, providing cost-effective versatility with seamless installation and easy maintenance. When comparing total expenses, engineered marble generally incurs higher upfront costs but delivers superior resistance to scratches and heat, potentially reducing long-term replacement and repair expenses.

Environmental Impact and Sustainability

Engineered marble uses natural marble chips bound with resin, which can include synthetic materials impacting biodegradability, while solid surface materials are predominantly acrylic-based polymers with varying eco-friendliness depending on manufacturing processes. Both materials offer durability that reduces the need for frequent replacement, but engineered marble often involves quarrying and resin production with higher carbon footprints compared to some solid surfaces formulated for recyclability and lower emissions. Selecting environmentally responsible engineered marble or solid surface options requires evaluating the source materials, production energy consumption, and end-of-life recyclability to minimize ecological impact and support sustainability goals.

Popular Applications in Homes and Commercial Spaces

Engineered marble is widely used in kitchen countertops and bathroom vanities due to its durability, resistance to stains, and variety of patterns, making it ideal for high-traffic residential and commercial areas. Solid surface materials excel in seamless installations for backsplashes, wall cladding, and custom sinks, offering non-porous, easy-to-maintain solutions popular in healthcare and hospitality settings. Both materials contribute to modern interior designs by providing aesthetic versatility and functional advantages tailored to specific applications.

Pros and Cons of Engineered Marble

Engineered marble offers enhanced durability and resistance to cracking compared to solid surface materials, making it ideal for high-traffic areas and heavy-use countertops. Its non-porous surface resists stains and bacterial growth, promoting hygiene, but engineered marble can be more prone to chipping under sharp impacts than solid surface options. While engineered marble mimics natural stone aesthetics with less maintenance required, it typically has limited heat resistance and may discolor if exposed to prolonged direct heat.

Pros and Cons of Solid Surface

Solid surface countertops offer excellent non-porous properties, making them highly resistant to stains and bacteria, an advantage over engineered marble that can absorb liquids. They provide seamless installation with easy repair options for scratches and minor damages, whereas engineered marble may chip or crack under impact. However, solid surfaces can be less heat resistant and prone to scratches compared to engineered marble, requiring careful maintenance around hot cookware and abrasive materials.

Engineered Marble vs Solid Surface Infographic

materialdif.com

materialdif.com