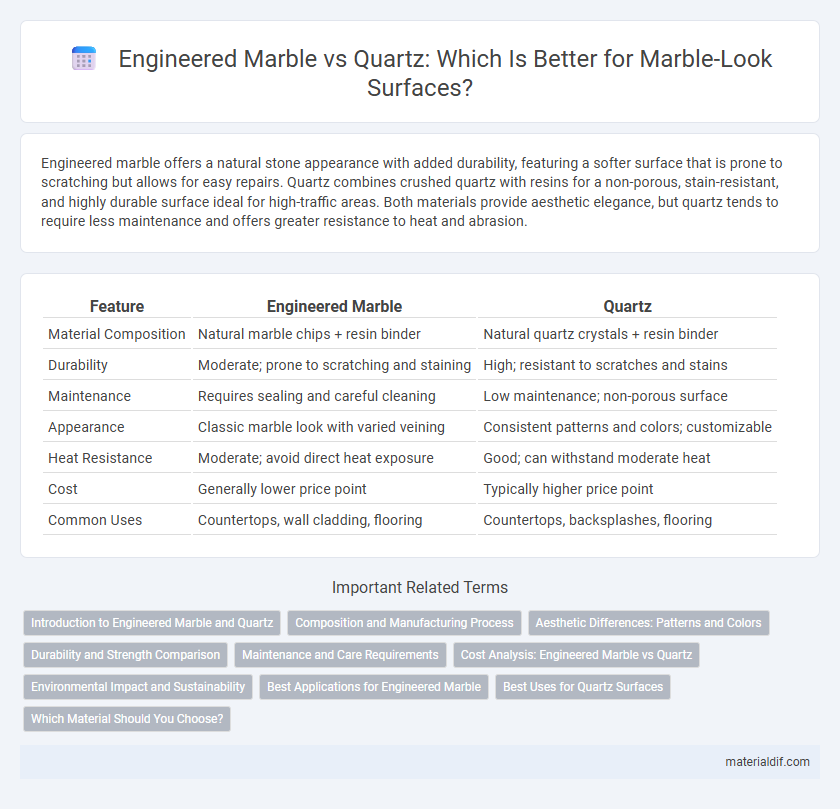

Engineered marble offers a natural stone appearance with added durability, featuring a softer surface that is prone to scratching but allows for easy repairs. Quartz combines crushed quartz with resins for a non-porous, stain-resistant, and highly durable surface ideal for high-traffic areas. Both materials provide aesthetic elegance, but quartz tends to require less maintenance and offers greater resistance to heat and abrasion.

Table of Comparison

| Feature | Engineered Marble | Quartz |

|---|---|---|

| Material Composition | Natural marble chips + resin binder | Natural quartz crystals + resin binder |

| Durability | Moderate; prone to scratching and staining | High; resistant to scratches and stains |

| Maintenance | Requires sealing and careful cleaning | Low maintenance; non-porous surface |

| Appearance | Classic marble look with varied veining | Consistent patterns and colors; customizable |

| Heat Resistance | Moderate; avoid direct heat exposure | Good; can withstand moderate heat |

| Cost | Generally lower price point | Typically higher price point |

| Common Uses | Countertops, wall cladding, flooring | Countertops, backsplashes, flooring |

Introduction to Engineered Marble and Quartz

Engineered marble is a composite material made from crushed natural marble mixed with resins and pigments, offering enhanced durability and consistent patterns compared to natural marble. Quartz surfaces consist primarily of natural quartz crystals combined with resins to create a non-porous, scratch-resistant, and low-maintenance countertop option. Both engineered marble and quartz provide aesthetic versatility and improved strength, making them popular choices for interior design and architectural applications.

Composition and Manufacturing Process

Engineered marble is composed primarily of crushed natural marble combined with resins and pigments, creating a material that mimics natural stone while enhancing durability. The manufacturing process involves blending these components and curing them under high pressure to form slabs with consistent texture and color. Quartz surfaces are made by combining approximately 90% natural quartz crystals with resins and pigments, then compressed and heated into durable, non-porous slabs through a vibration and curing process.

Aesthetic Differences: Patterns and Colors

Engineered marble features unique veining patterns and a more natural stone appearance with subtle color variations, while quartz offers a broader palette of consistent, vibrant colors with uniform patterns. The intricate patterns of engineered marble create an elegant, classic look, whereas quartz surfaces provide modern, sleek aesthetics with customizable hues. Quartz's engineered composition allows for more precise control over color and pattern, appealing to contemporary design trends.

Durability and Strength Comparison

Engineered marble offers moderate durability with a surface hardness typically ranging between 3 to 4 on the Mohs scale, making it more prone to scratches and chips compared to quartz. Quartz, composed of approximately 90% natural quartz crystals, has a higher hardness rating of around 7 on the Mohs scale, providing superior strength and resistance to wear, impact, and staining. The non-porous nature of quartz also enhances its durability by preventing moisture absorption and bacterial growth, which are common issues affecting engineered marble surfaces.

Maintenance and Care Requirements

Engineered marble requires regular sealing to maintain its stain resistance and prevent etching, while quartz surfaces are non-porous and need minimal sealing, making them easier to maintain. Both materials benefit from gentle, non-abrasive cleaners to avoid surface damage, but quartz's durability offers superior resistance to scratches and stains. Proper care of engineered marble involves prompt cleaning of spills to prevent damage, whereas quartz's low maintenance nature is ideal for busy kitchens and high-traffic areas.

Cost Analysis: Engineered Marble vs Quartz

Engineered marble typically costs between $40 and $60 per square foot, making it a more affordable option compared to quartz, which ranges from $50 to $120 per square foot depending on quality and brand. Installation prices for both materials are similar, averaging $35 to $50 per hour, but quartz's higher material cost often results in a greater total investment. Long-term maintenance expenses also favor engineered marble, as quartz requires less frequent sealing and is more resistant to stains and scratches, potentially lowering upkeep costs over time.

Environmental Impact and Sustainability

Engineered marble often contains resins and polymers that can release volatile organic compounds (VOCs) during manufacturing and disposal, raising environmental concerns. Quartz countertops, composed primarily of natural quartz combined with resin binders, offer greater durability and lower porosity, which reduces waste and maintenance needs over time. Sustainable options emphasize recycled content in quartz surfaces and eco-friendly production processes to minimize carbon footprint compared to traditional engineered marble.

Best Applications for Engineered Marble

Engineered marble is best suited for interior surfaces such as countertops, vanity tops, and flooring due to its durability and low porosity. Its consistent pattern and color make it ideal for modern kitchen and bathroom designs where aesthetics and easy maintenance are crucial. Unlike quartz, engineered marble is less heat-resistant, so it is not recommended for outdoor use or areas exposed to high temperatures.

Best Uses for Quartz Surfaces

Quartz surfaces are highly durable and resistant to stains, making them ideal for kitchen countertops and high-traffic areas. Their non-porous nature prevents bacterial growth, ensuring hygienic surfaces for food preparation and bathrooms. Engineered quartz also offers a wide range of colors and patterns, providing versatile design options for both residential and commercial spaces.

Which Material Should You Choose?

Engineered marble offers a natural stone appearance with improved durability and stain resistance, making it ideal for bathrooms and moderate-use countertops. Quartz provides superior hardness and non-porous properties, ensuring low maintenance and higher resistance to scratches and heat, perfect for heavy-use kitchen surfaces. Choosing between engineered marble and quartz depends on balancing aesthetic preferences with functional requirements and budget constraints.

Engineered Marble vs Quartz Infographic

materialdif.com

materialdif.com