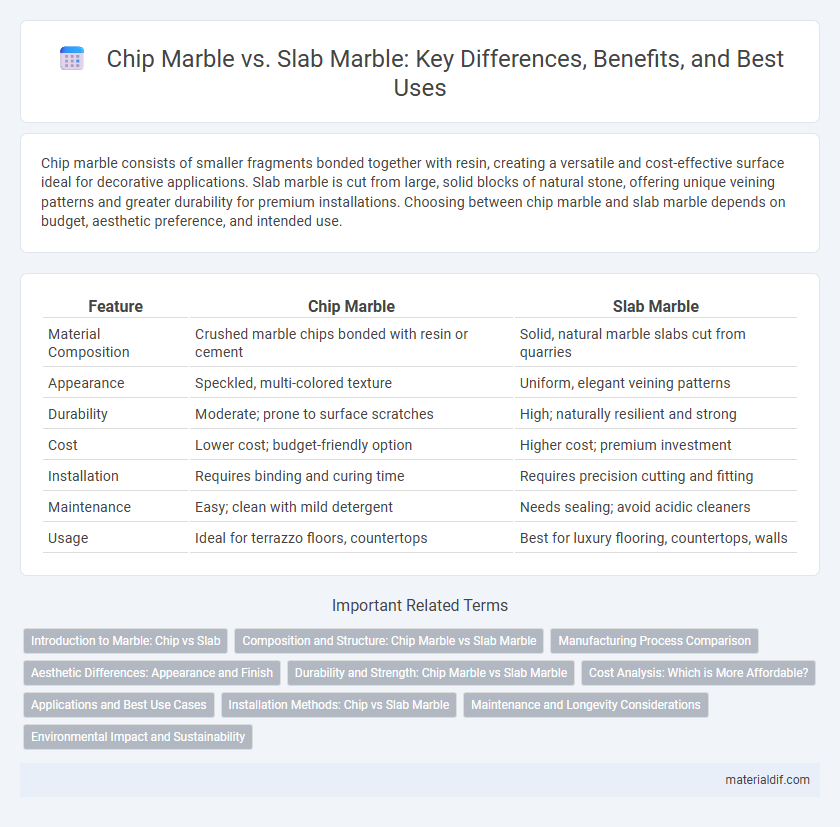

Chip marble consists of smaller fragments bonded together with resin, creating a versatile and cost-effective surface ideal for decorative applications. Slab marble is cut from large, solid blocks of natural stone, offering unique veining patterns and greater durability for premium installations. Choosing between chip marble and slab marble depends on budget, aesthetic preference, and intended use.

Table of Comparison

| Feature | Chip Marble | Slab Marble |

|---|---|---|

| Material Composition | Crushed marble chips bonded with resin or cement | Solid, natural marble slabs cut from quarries |

| Appearance | Speckled, multi-colored texture | Uniform, elegant veining patterns |

| Durability | Moderate; prone to surface scratches | High; naturally resilient and strong |

| Cost | Lower cost; budget-friendly option | Higher cost; premium investment |

| Installation | Requires binding and curing time | Requires precision cutting and fitting |

| Maintenance | Easy; clean with mild detergent | Needs sealing; avoid acidic cleaners |

| Usage | Ideal for terrazzo floors, countertops | Best for luxury flooring, countertops, walls |

Introduction to Marble: Chip vs Slab

Chip marble consists of small, irregular pieces of marble bonded together with resin or cement to create a composite surface, offering enhanced durability and cost-effectiveness. Slab marble is quarried in large, continuous blocks, showcasing natural veining and patterns, ideal for high-end countertops and architectural features. Choosing between chip marble and slab marble depends on aesthetic preferences, budget, and intended use in residential or commercial settings.

Composition and Structure: Chip Marble vs Slab Marble

Chip marble consists of small, irregular fragments of natural marble bonded together with resin or cement, creating a composite material with enhanced durability and varied textures. Slab marble is a solid piece of natural marble quarried in large, uniform blocks, preserving the stone's natural veining and crystalline structure. The composition of chip marble allows for more design flexibility and resistance to cracking, while slab marble offers a consistent surface with authentic marble characteristics.

Manufacturing Process Comparison

Chip marble manufacturing involves mixing marble chips with resin or cement, creating a composite material that is molded and cured into various shapes, ensuring durability and customization. Slab marble is quarried from natural stone blocks, then cut and polished into large slabs, preserving the stone's unique veining and texture but requiring more intensive processing and higher costs. The chip marble process allows for consistent quality and variety, while slab marble maintains natural authenticity with more complex extraction and finishing methods.

Aesthetic Differences: Appearance and Finish

Chip marble exhibits a speckled, irregular pattern with diverse color fragments embedded in a resin or cement base, creating a vibrant, mosaic-like appearance ideal for artistic and decorative applications. Slab marble offers a more uniform and natural veined look, showcasing continuous, flowing patterns with smooth, polished finishes that highlight the stone's inherent elegance and classic beauty. The finish on chip marble is often glossy but textured, while slab marble typically features a high-gloss, smooth surface that enhances its luxurious and timeless appeal.

Durability and Strength: Chip Marble vs Slab Marble

Slab marble generally offers superior durability and strength compared to chip marble due to its solid, continuous composition and greater thickness. Chip marble, composed of smaller fragments bonded by resin or cement, tends to be less resistant to impact and wear over time. For high-traffic areas and long-lasting installations, slab marble is the preferred option because it maintains structural integrity and resists cracking more effectively.

Cost Analysis: Which is More Affordable?

Chip marble, composed of smaller fragments bonded together, generally costs less than slab marble, making it a budget-friendly option for large surfaces. Slab marble, quarried in large pieces, demands higher extraction, transportation, and finishing expenses, resulting in a premium price. Analyzing the total cost including installation and maintenance reveals chip marble as the more affordable choice for cost-conscious projects.

Applications and Best Use Cases

Chip marble, composed of small fragments bonded with resin, excels in intricate designs and mosaic patterns ideal for decorative surfaces and smaller-scale installations. Slab marble, sourced as large, continuous pieces, suits expansive applications like flooring, countertops, and wall cladding where uniformity and durability are critical. Selecting chip marble benefits artistic and custom projects, while slab marble supports high-traffic areas requiring structural integrity and seamless aesthetics.

Installation Methods: Chip vs Slab Marble

Chip marble installation involves embedding small marble fragments into a resin or cement base, creating a terrazzo-like surface that requires polishing after curing to achieve a smooth finish. Slab marble installation uses large, polished stone slabs secured with adhesives or mechanical fasteners, demanding precise cutting and leveling for seamless joints and a uniform surface. Chip marble offers flexible shapes and easier repairs, while slab marble provides durability and a natural stone aesthetic through more intensive labor and specialized tools.

Maintenance and Longevity Considerations

Chip marble requires more frequent sealing and gentle cleaning methods to prevent surface damage due to its porous nature, while slab marble offers greater durability with less intensive upkeep. Slab marble typically exhibits enhanced longevity because of its thicker, solid composition, resisting cracks and wear better than chipped varieties. Proper maintenance of both types ensures preservation of polish and structural integrity, with slab marble demanding less frequent restorations over time.

Environmental Impact and Sustainability

Chip marble, composed of smaller marble fragments bonded together, typically has a lower environmental impact due to reduced quarry waste and more efficient use of raw materials. Slab marble involves cutting large blocks, leading to greater quarrying waste and higher energy consumption during extraction and transportation. Choosing chip marble supports sustainability by minimizing resource depletion and promoting recycling of marble remnants.

Chip Marble vs Slab Marble Infographic

materialdif.com

materialdif.com