Engineered marble offers greater durability and uniformity compared to solid marble, making it ideal for high-traffic areas and modern interior designs. Solid marble boasts natural veining and unique patterns that enhance aesthetic appeal but requires more maintenance due to its porous nature. Choosing between engineered and solid marble depends on the balance between desired appearance, durability, and maintenance requirements.

Table of Comparison

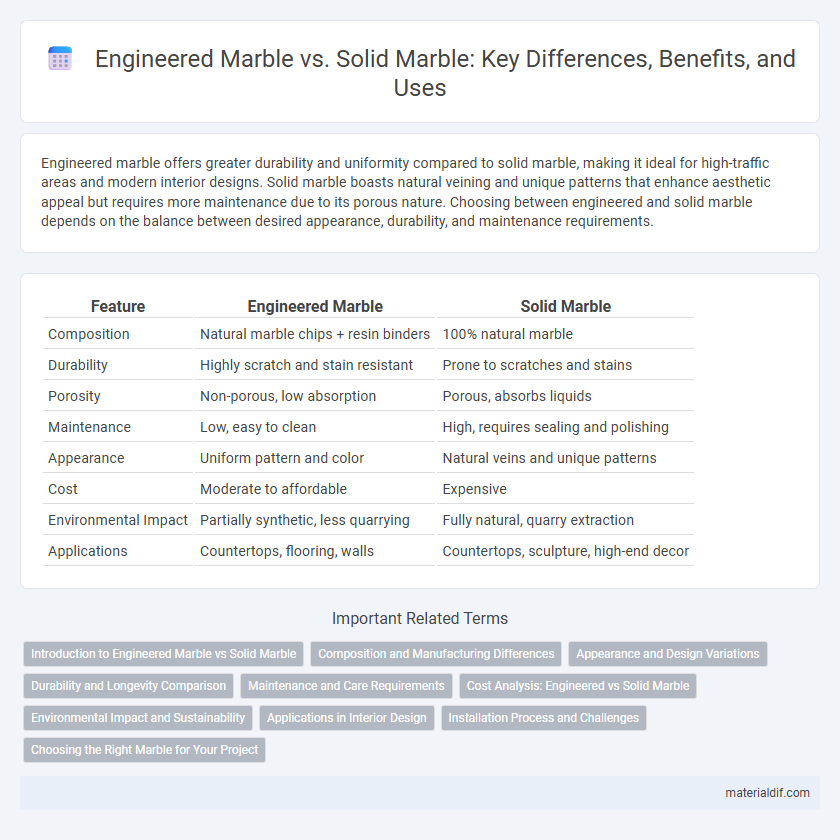

| Feature | Engineered Marble | Solid Marble |

|---|---|---|

| Composition | Natural marble chips + resin binders | 100% natural marble |

| Durability | Highly scratch and stain resistant | Prone to scratches and stains |

| Porosity | Non-porous, low absorption | Porous, absorbs liquids |

| Maintenance | Low, easy to clean | High, requires sealing and polishing |

| Appearance | Uniform pattern and color | Natural veins and unique patterns |

| Cost | Moderate to affordable | Expensive |

| Environmental Impact | Partially synthetic, less quarrying | Fully natural, quarry extraction |

| Applications | Countertops, flooring, walls | Countertops, sculpture, high-end decor |

Introduction to Engineered Marble vs Solid Marble

Engineered marble combines marble particles with resins and pigments, offering enhanced durability and uniformity compared to solid marble, which is a natural stone formed through geological processes. While solid marble features unique veining and natural imperfections prized for aesthetics, engineered marble provides increased resistance to stains, scratches, and moisture due to its composite structure. Selecting between engineered and solid marble depends on priorities such as maintenance, cost, and desired appearance in construction or interior design projects.

Composition and Manufacturing Differences

Engineered marble is composed of crushed natural marble mixed with resin and pigments, providing enhanced durability and uniformity, while solid marble is a natural stone formed through mineral crystallization over millions of years. The manufacturing process of engineered marble involves molding and curing under controlled conditions, allowing customization of color and pattern, whereas solid marble requires quarrying, cutting, and polishing to reveal its inherent veining and texture. These compositional and manufacturing differences contribute to engineered marble's resistance to staining and cracking compared to the porous and more brittle nature of solid marble.

Appearance and Design Variations

Engineered marble offers a consistent and uniform appearance with a wide range of customizable colors and patterns, making it ideal for modern, versatile designs. In contrast, solid marble showcases natural veining and unique variations that provide a luxurious, one-of-a-kind aesthetic. The choice between engineered and solid marble depends on whether a predictable design or natural elegance is preferred.

Durability and Longevity Comparison

Engineered marble offers enhanced durability due to its composite structure, combining natural marble with resins, making it resistant to cracking and staining compared to solid marble. Solid marble, while naturally beautiful and unique, is more porous and susceptible to scratches, etching, and weathering over time. The longevity of engineered marble generally exceeds that of solid marble in high-traffic or moisture-prone areas, as it maintains its integrity with less maintenance and fewer repairs.

Maintenance and Care Requirements

Engineered marble requires less maintenance compared to solid marble due to its non-porous surface, which resists stains and does not need frequent sealing. Solid marble demands regular sealing and careful cleaning with pH-neutral products to prevent etching and discoloration from acidic substances. Both materials benefit from prompt spill cleanup, but engineered marble offers easier long-term durability and upkeep for high-traffic areas.

Cost Analysis: Engineered vs Solid Marble

Engineered marble typically costs between $50 and $100 per square foot, making it more affordable than solid marble, which ranges from $75 to $200 per square foot depending on the quality and origin. Installation costs for engineered marble are generally lower due to its uniformity and easier fabrication process, while solid marble requires skilled labor and more time. Maintenance expenses are also reduced with engineered marble, as it resists stains and cracks better than porous solid marble, leading to lower long-term costs.

Environmental Impact and Sustainability

Engineered marble combines natural marble dust with resins, reducing quarrying impact and minimizing waste compared to solid marble extraction, which involves extensive mining and habitat disruption. The production of engineered marble allows for recycled materials to be incorporated, enhancing sustainability, while solid marble's inherent resource intensity and carbon footprint are higher due to energy-intensive cutting and transportation. Both materials can be long-lasting, but engineered marble offers greater potential for eco-friendly manufacturing and reduced environmental degradation.

Applications in Interior Design

Engineered marble offers versatility and durability, making it ideal for kitchen countertops, bathroom vanities, and wall cladding where resistance to stains and scratches is crucial. Solid marble provides timeless elegance and natural veining, favored in flooring, fireplaces, and decorative accents for luxurious interior aesthetics. Both materials enable unique design applications, but engineered marble's consistency suits modern, high-traffic areas while solid marble enhances classic, upscale spaces.

Installation Process and Challenges

Engineered marble offers a more straightforward installation process due to its uniform thickness and lighter weight, reducing labor time and the risk of cracks during handling. Solid marble installation requires precise cutting and sealing to manage its natural veining and porosity, making the process more labor-intensive and susceptible to chipping. Challenges with solid marble include ensuring proper support to avoid fractures, while engineered marble's consistent composition simplifies fitting and finishing in various architectural applications.

Choosing the Right Marble for Your Project

Engineered marble offers consistent color and pattern with enhanced durability, making it ideal for high-traffic areas and budget-conscious projects. Solid marble features natural veining and unique textures, providing timeless elegance and higher heat resistance suited for luxury and classic designs. Consider project requirements such as maintenance, aesthetics, and budget to choose between engineered and solid marble effectively.

Engineered marble vs solid marble Infographic

materialdif.com

materialdif.com