Marble composite combines crushed natural marble with resins to create a durable, cost-effective surface that mimics the beauty of natural stone while offering improved resistance to stains and scratches. Engineered marble uses a similar process but typically includes a higher concentration of resin and pigments, resulting in greater uniformity and enhanced flexibility in design options. Both materials provide elegant, low-maintenance alternatives to natural marble, with engineered marble often preferred for its enhanced durability and consistent appearance.

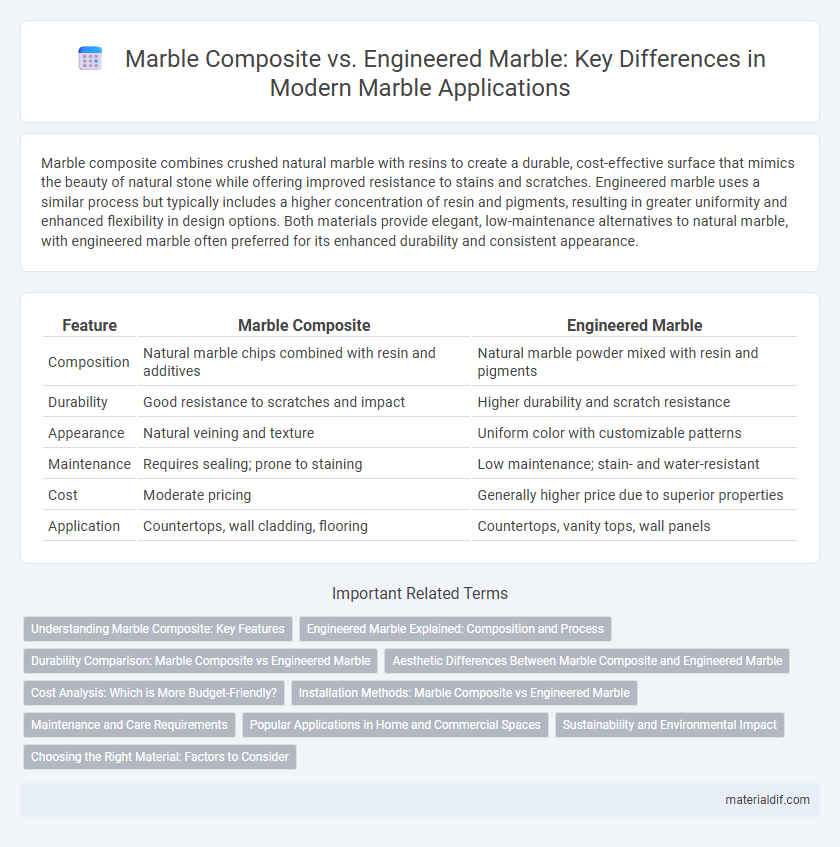

Table of Comparison

| Feature | Marble Composite | Engineered Marble |

|---|---|---|

| Composition | Natural marble chips combined with resin and additives | Natural marble powder mixed with resin and pigments |

| Durability | Good resistance to scratches and impact | Higher durability and scratch resistance |

| Appearance | Natural veining and texture | Uniform color with customizable patterns |

| Maintenance | Requires sealing; prone to staining | Low maintenance; stain- and water-resistant |

| Cost | Moderate pricing | Generally higher price due to superior properties |

| Application | Countertops, wall cladding, flooring | Countertops, vanity tops, wall panels |

Understanding Marble Composite: Key Features

Marble composite consists of natural marble fragments blended with resin and pigments, offering enhanced durability and versatility compared to natural marble. This material provides resistance to staining, scratching, and heat, making it ideal for countertops and flooring in high-traffic areas. Engineered marble, while similar, often contains a higher resin content, resulting in a smoother surface but slightly less natural veining than marble composite.

Engineered Marble Explained: Composition and Process

Engineered marble is composed of crushed natural marble combined with resins and pigments, resulting in a highly durable and non-porous surface. The manufacturing process involves mixing these materials, casting them into slabs, and curing under heat and pressure to enhance strength and consistency. This engineered composition offers greater resistance to stains and scratches compared to natural marble, making it ideal for various interior applications.

Durability Comparison: Marble Composite vs Engineered Marble

Marble composite combines natural marble chips with resin, resulting in a surface that offers moderate durability and resistance to stains and scratches but may be susceptible to heat damage over time. Engineered marble, composed primarily of crushed natural marble bound with resin, provides enhanced durability with higher resistance to impact, moisture, and UV exposure, making it more suitable for high-traffic areas. Both materials require maintenance, but engineered marble generally outperforms marble composite in long-term durability and resilience against wear.

Aesthetic Differences Between Marble Composite and Engineered Marble

Marble composite surfaces often feature a more natural, varied appearance with unique veining patterns that mimic genuine stone, appealing to those seeking authenticity in design. Engineered marble typically offers a uniform texture and consistent coloration, providing a sleek, modern aesthetic ideal for contemporary interiors. The choice between the two hinges on whether a natural, organic look or a polished, controlled finish best suits the overall design goals.

Cost Analysis: Which is More Budget-Friendly?

Marble composite typically offers a more budget-friendly option compared to engineered marble due to its lower manufacturing costs and use of recycled materials. Engineered marble, which blends natural marble dust with resins and pigments, demands higher production expenses, reflected in its price. Homeowners seeking cost efficiency often prefer marble composite for budget-conscious renovations or installations.

Installation Methods: Marble Composite vs Engineered Marble

Marble composite typically requires adhesive bonding to secure the material onto surfaces, often involving a substrate for enhanced stability, making the installation process straightforward but reliant on proper surface preparation. Engineered marble installation uses resin compounds that allow for precision cutting and seamless joining, offering flexibility in shaping and fitting complex designs with minimal grout lines. Both methods demand professional handling to ensure durability and a polished finish, but engineered marble's uniformity often reduces installation time compared to marble composite.

Maintenance and Care Requirements

Marble composite requires regular sealing and gentle cleaning with pH-neutral products to prevent staining and preserve its polished surface, while engineered marble demands less frequent sealing due to its resin-infused properties that enhance stain and scratch resistance. Both materials benefit from prompt spill cleanup and avoiding abrasive cleaners to maintain their aesthetic appeal over time. Engineered marble generally offers easier maintenance, making it suitable for high-traffic areas with less upkeep compared to traditional marble composite.

Popular Applications in Home and Commercial Spaces

Marble composite, made from crushed natural marble bound with resin, offers superior durability and stain resistance, making it ideal for kitchen countertops and bathroom vanities in both residential and commercial settings. Engineered marble, composed of natural marble aggregates combined with polymers, excels in creating seamless surfaces and intricate shapes, commonly used in decorative wall panels and custom furniture. Both materials are favored in hospitality and retail environments for their aesthetic appeal and functional versatility.

Sustainability and Environmental Impact

Marble composite combines natural marble fragments with resin, reducing the need for extensive quarrying and minimizing waste, making it a more sustainable choice compared to engineered marble, which often involves synthetic materials and higher energy-intensive manufacturing processes. Engineered marble typically uses a blend of crushed marble and polymers, leading to increased carbon emissions and non-biodegradable components. Choosing marble composite supports resource efficiency and lowers environmental impact by utilizing reclaimed stone and reducing raw material extraction.

Choosing the Right Material: Factors to Consider

Choosing between marble composite and engineered marble depends on durability, maintenance, and aesthetic preferences. Marble composite offers natural stone fragments bonded with resin, providing enhanced strength and resistance to staining, ideal for high-traffic areas. Engineered marble combines natural marble dust with resin for uniform patterns and increased non-porosity, making it easier to clean and suitable for kitchen countertops and bathrooms.

Marble Composite vs Engineered Marble Infographic

materialdif.com

materialdif.com