Handcrafted marble offers unique, artisanal detailing with natural variations that emphasize its exclusive beauty, while machine-cut marble provides consistent precision and uniformity ideal for large-scale projects. The tactile craftsmanship in handcrafted marble results in subtle imperfections that enhance its aesthetic appeal, contrasting with the smooth, exact edges achieved through machine cutting. Choosing between the two depends on whether authenticity and individuality or speed and consistency are prioritized for the marble pet design.

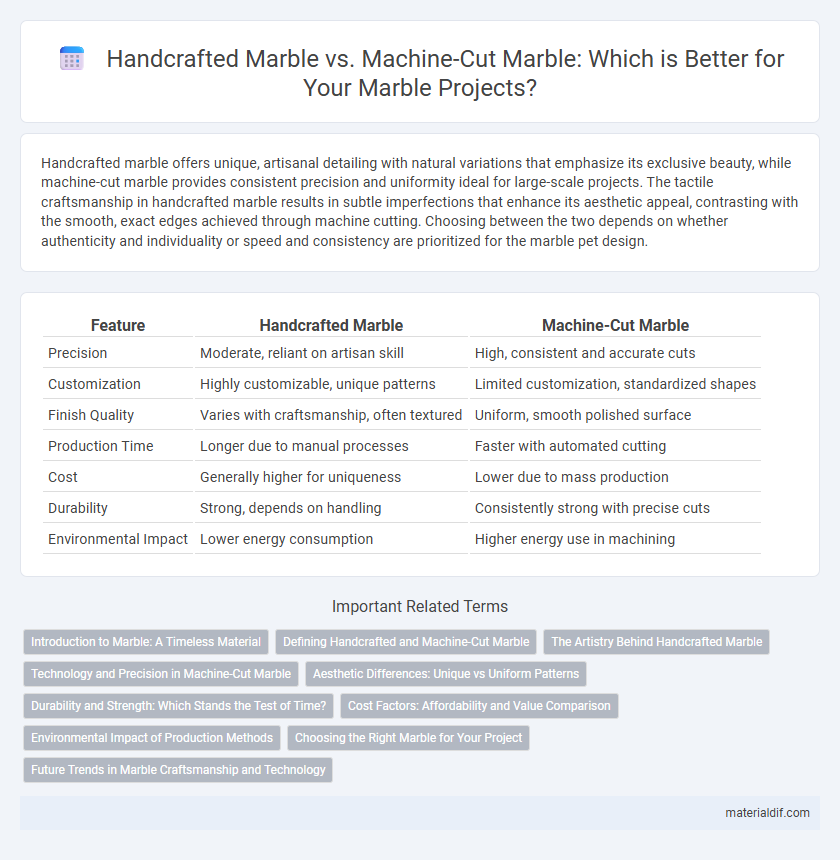

Table of Comparison

| Feature | Handcrafted Marble | Machine-Cut Marble |

|---|---|---|

| Precision | Moderate, reliant on artisan skill | High, consistent and accurate cuts |

| Customization | Highly customizable, unique patterns | Limited customization, standardized shapes |

| Finish Quality | Varies with craftsmanship, often textured | Uniform, smooth polished surface |

| Production Time | Longer due to manual processes | Faster with automated cutting |

| Cost | Generally higher for uniqueness | Lower due to mass production |

| Durability | Strong, depends on handling | Consistently strong with precise cuts |

| Environmental Impact | Lower energy consumption | Higher energy use in machining |

Introduction to Marble: A Timeless Material

Marble, a natural stone renowned for its elegance and durability, offers unique characteristics whether handcrafted or machine-cut. Handcrafted marble showcases artisanal skill, resulting in intricate designs and personalized details that highlight the stone's natural veining and texture. Machine-cut marble ensures precision and uniformity, ideal for large-scale projects requiring consistency and speed without compromising the material's timeless beauty.

Defining Handcrafted and Machine-Cut Marble

Handcrafted marble involves artisans shaping and finishing each piece manually, emphasizing unique, intricate details and traditional craftsmanship. Machine-cut marble uses automated tools and precise technology to produce uniform cuts and consistent dimensions at a faster rate. The distinction lies in the personalized artistry of handcrafted marble versus the efficiency and repeatability of machine-cut marble.

The Artistry Behind Handcrafted Marble

Handcrafted marble showcases unparalleled artistry through meticulous carving and individualized detailing that machines cannot replicate, creating unique textures and intricate patterns. Skilled artisans use traditional tools to enhance the stone's natural beauty, ensuring each piece is a one-of-a-kind masterpiece with subtle variations. This personalized craftsmanship offers a tactile depth and character that contrasts sharply with the uniform precision of machine-cut marble.

Technology and Precision in Machine-Cut Marble

Machine-cut marble leverages advanced CNC technology and laser-guided tools to achieve unmatched precision and uniformity in each slab, minimizing material waste and defects. The integration of computer-aided design (CAD) allows for intricate patterns and exact dimensions that are difficult to replicate by hand. This technological advancement enhances consistency and efficiency, making machine-cut marble ideal for large-scale architectural and interior design projects.

Aesthetic Differences: Unique vs Uniform Patterns

Handcrafted marble showcases unique, irregular patterns that highlight the artisan's skill and emphasize natural variations in the stone, creating one-of-a-kind aesthetic appeal. Machine-cut marble offers uniform patterns and precise edges, delivering consistent and symmetrical designs well-suited for modern, minimalist spaces. The choice between handcrafted and machine-cut marble depends on preference for individuality versus predictability in visual texture and pattern.

Durability and Strength: Which Stands the Test of Time?

Handcrafted marble offers unique durability due to meticulous artisan techniques that preserve the stone's natural integrity, resulting in fewer micro-fractures compared to machine-cut marble. Machine-cut marble benefits from precision and consistent thickness, which enhances structural strength and uniform load distribution in architectural applications. Over time, handcrafted marble may exhibit more character through natural wear, while machine-cut marble emphasizes long-term resilience and uniform strength.

Cost Factors: Affordability and Value Comparison

Handcrafted marble typically involves higher labor costs due to skilled artisan techniques, making it less affordable but often more valuable for unique, intricate designs. Machine-cut marble offers consistent precision and faster production, reducing overall expenses and making it a more cost-effective option for larger projects. The value comparison depends on budget constraints and desired aesthetic, with handcrafted marble prized for exclusivity and machine-cut preferred for efficiency and affordability.

Environmental Impact of Production Methods

Handcrafted marble production typically involves less energy consumption compared to machine-cut marble, resulting in a lower carbon footprint. Manual techniques generate minimal waste and reduce reliance on fossil fuels, promoting sustainable quarrying practices. In contrast, machine-cut marble requires high electricity usage and often produces significant stone debris, contributing to environmental degradation.

Choosing the Right Marble for Your Project

Handcrafted marble offers unique textures and intricate details that enhance luxury design projects, while machine-cut marble provides precise dimensions and uniformity ideal for large-scale installations. Selecting the right marble depends on project requirements such as aesthetic preference, budget constraints, and installation complexity. Consider handcrafted options for bespoke, artistic elements, and machine-cut marble for consistency and efficiency in commercial or modern architectural applications.

Future Trends in Marble Craftsmanship and Technology

Handcrafted marble showcases intricate artistry and unique patterns, often valued for its bespoke aesthetic and traditional techniques. Machine-cut marble leverages precision technology, enabling faster production, consistent quality, and complex designs through CNC routers and waterjet cutting. Future trends in marble craftsmanship emphasize integrating AI-driven tools with artisan skills, enhancing efficiency while preserving the marble's natural beauty and uniqueness.

Handcrafted Marble vs Machine-Cut Marble Infographic

materialdif.com

materialdif.com