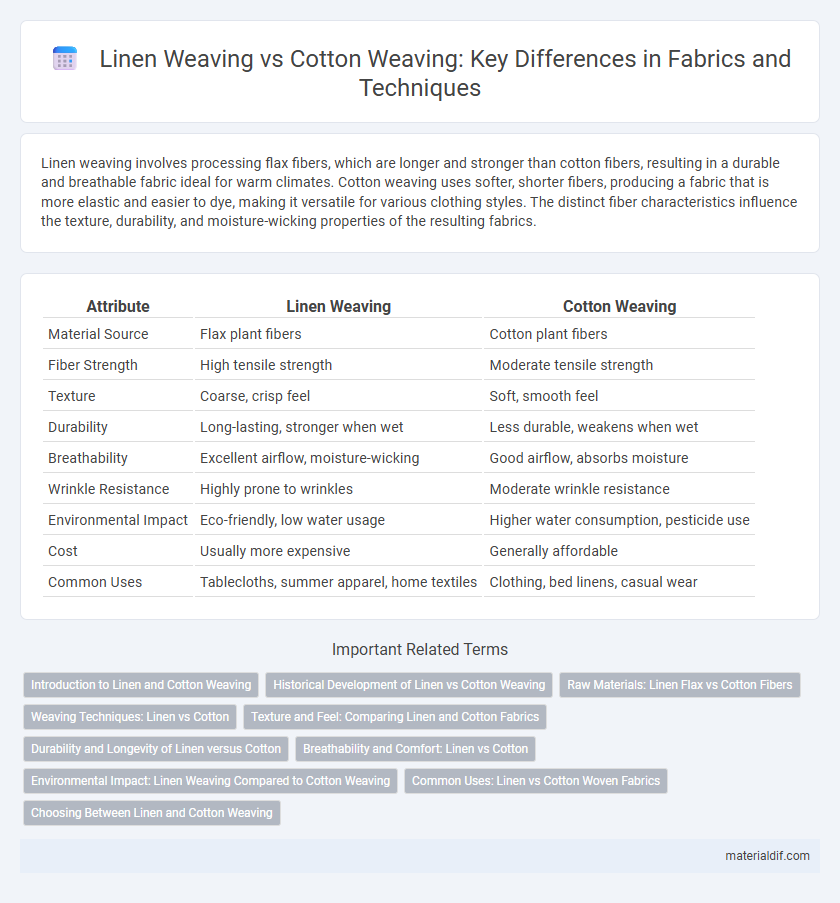

Linen weaving involves processing flax fibers, which are longer and stronger than cotton fibers, resulting in a durable and breathable fabric ideal for warm climates. Cotton weaving uses softer, shorter fibers, producing a fabric that is more elastic and easier to dye, making it versatile for various clothing styles. The distinct fiber characteristics influence the texture, durability, and moisture-wicking properties of the resulting fabrics.

Table of Comparison

| Attribute | Linen Weaving | Cotton Weaving |

|---|---|---|

| Material Source | Flax plant fibers | Cotton plant fibers |

| Fiber Strength | High tensile strength | Moderate tensile strength |

| Texture | Coarse, crisp feel | Soft, smooth feel |

| Durability | Long-lasting, stronger when wet | Less durable, weakens when wet |

| Breathability | Excellent airflow, moisture-wicking | Good airflow, absorbs moisture |

| Wrinkle Resistance | Highly prone to wrinkles | Moderate wrinkle resistance |

| Environmental Impact | Eco-friendly, low water usage | Higher water consumption, pesticide use |

| Cost | Usually more expensive | Generally affordable |

| Common Uses | Tablecloths, summer apparel, home textiles | Clothing, bed linens, casual wear |

Introduction to Linen and Cotton Weaving

Linen weaving involves processing fibers from the flax plant, producing a strong, breathable fabric known for its durability and natural luster, while cotton weaving derives fibers from cotton plants, yielding a softer and more versatile textile popular in everyday apparel. The structural differences in flax and cotton fibers influence weaving techniques, with linen often requiring finer, tighter weaves to enhance its smooth texture and strength compared to the typically looser cotton weaves. Both weaving processes utilize warp and weft interlacing, but linen demands greater expertise due to its fiber rigidity and tendency to wrinkle less than cotton during fabric formation.

Historical Development of Linen vs Cotton Weaving

Linen weaving traces back over 8,000 years, originating in ancient Egypt where flax fibers were hand-spun and woven into durable, breathable textiles used for clothing and burial shrouds. Cotton weaving emerged later around 5,000 years ago in the Indus Valley Civilization, with advancements in spinning and loom technology enabling mass production and widespread trade. The historical shift from linen to cotton weaving marked significant industrial and cultural developments, influencing global textile markets and fabric preferences.

Raw Materials: Linen Flax vs Cotton Fibers

Linen weaving utilizes flax fibers derived from the flax plant, known for their long, strong, and smooth characteristics, resulting in durable and breathable fabric. Cotton weaving relies on short, fluffy cotton fibers harvested from the cotton plant, offering softness and flexibility but generally less tensile strength compared to flax fibers. The intrinsic differences in raw materials significantly impact the texture, strength, and moisture-wicking properties of linen versus cotton textiles.

Weaving Techniques: Linen vs Cotton

Linen weaving involves extracting fibers from the flax plant, resulting in long, strong fibers ideal for creating durable, smooth fabrics with a natural sheen through techniques like plain weaving and twill. Cotton weaving uses shorter, softer fibers from the cotton plant, typically woven into versatile, breathable fabrics using methods such as plain weave, sateen, and twill. The difference in fiber length and texture influences the weaving approach, with linen requiring more precise handling to maintain its strength and cotton allowing for a wider variety of weave patterns.

Texture and Feel: Comparing Linen and Cotton Fabrics

Linen weaving produces a fabric with a distinctively crisp texture and natural breathability, making it ideal for warm climates due to its moisture-wicking properties. Cotton weaving results in a softer, smoother fabric with greater elasticity, providing enhanced comfort and versatility for various clothing styles. The tactile difference stems from flax fibers in linen, which create a coarser, more durable weave, whereas cotton fibers yield a plush, flexible surface.

Durability and Longevity of Linen versus Cotton

Linen weaving produces fabric with superior durability compared to cotton, as flax fibers used in linen are thicker and stronger, resulting in textiles that resist wear and tear longer. Linen's natural resistance to pilling and its ability to become softer without losing strength contribute to its exceptional longevity. Cotton fibers, while softer initially, tend to weaken with repeated washing and abrasion, making linen the preferred choice for long-lasting woven fabrics.

Breathability and Comfort: Linen vs Cotton

Linen weaving creates fabric with larger fibers and a looser weave, resulting in superior breathability and moisture-wicking properties compared to cotton. Cotton weaving produces a softer texture but tends to retain more heat and moisture, making it less breathable in warm conditions. The natural structure of linen fibers allows for enhanced airflow and quicker drying, offering greater comfort in hot, humid climates.

Environmental Impact: Linen Weaving Compared to Cotton Weaving

Linen weaving has a significantly lower environmental impact than cotton weaving due to flax's minimal water and pesticide requirements, reducing resource consumption and soil degradation. The production of linen emits fewer greenhouse gases and demands less energy, making it a more sustainable choice compared to conventional cotton cultivation. Additionally, linen fibers are biodegradable and durable, enhancing environmental benefits through longer product lifecycle and reduced waste.

Common Uses: Linen vs Cotton Woven Fabrics

Linen woven fabrics are prized for their durability and moisture-wicking properties, making them ideal for summer clothing, table linens, and home decor like curtains and upholstery. Cotton woven fabrics offer softness and breathability, commonly used in everyday apparel, bed linens, and casual wear. Both fibers serve distinct purposes, with linen favored for its crisp texture and cotton for its comfort and versatility.

Choosing Between Linen and Cotton Weaving

Linen weaving typically produces a stronger, more breathable fabric ideal for warm climates, while cotton weaving offers softer, more flexible textiles suitable for everyday wear. Linen fibers come from flax plants, resulting in durability and moisture-wicking properties, whereas cotton fibers are shorter and softer, enhancing comfort and ease of care. Choosing between linen and cotton weaving depends on desired texture, durability, climate, and end-use of the fabric.

Linen Weaving vs Cotton Weaving Infographic

materialdif.com

materialdif.com