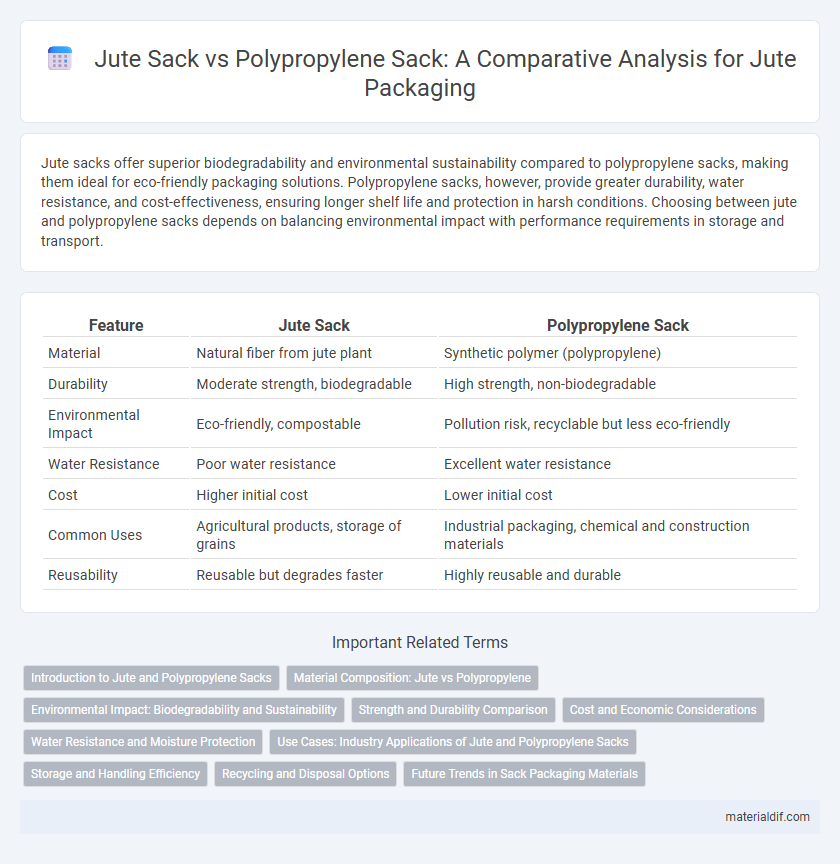

Jute sacks offer superior biodegradability and environmental sustainability compared to polypropylene sacks, making them ideal for eco-friendly packaging solutions. Polypropylene sacks, however, provide greater durability, water resistance, and cost-effectiveness, ensuring longer shelf life and protection in harsh conditions. Choosing between jute and polypropylene sacks depends on balancing environmental impact with performance requirements in storage and transport.

Table of Comparison

| Feature | Jute Sack | Polypropylene Sack |

|---|---|---|

| Material | Natural fiber from jute plant | Synthetic polymer (polypropylene) |

| Durability | Moderate strength, biodegradable | High strength, non-biodegradable |

| Environmental Impact | Eco-friendly, compostable | Pollution risk, recyclable but less eco-friendly |

| Water Resistance | Poor water resistance | Excellent water resistance |

| Cost | Higher initial cost | Lower initial cost |

| Common Uses | Agricultural products, storage of grains | Industrial packaging, chemical and construction materials |

| Reusability | Reusable but degrades faster | Highly reusable and durable |

Introduction to Jute and Polypropylene Sacks

Jute sacks are biodegradable, eco-friendly packaging solutions made from natural fibers derived from the jute plant, known for their durability and breathability. Polypropylene sacks, made from synthetic polymers, offer high tensile strength, moisture resistance, and cost-effective mass production but lack environmental sustainability. Both types are widely used in agriculture and industry for storage and transport, with jute preferred for organic products and polypropylene favored for moisture-sensitive goods.

Material Composition: Jute vs Polypropylene

Jute sacks are made from natural vegetable fibers derived from the jute plant, offering biodegradability and breathability, ideal for storing agricultural products. Polypropylene sacks consist of synthetic polymers derived from petroleum, providing high tensile strength, moisture resistance, and durability in harsh environmental conditions. The material composition directly impacts sustainability, reuse potential, and suitability for different storage needs.

Environmental Impact: Biodegradability and Sustainability

Jute sacks are highly biodegradable, decomposing naturally within months without leaving harmful residues, making them a sustainable choice for eco-friendly packaging. In contrast, polypropylene sacks, derived from non-renewable petroleum, persist in the environment for hundreds of years, contributing to plastic pollution and landfill overflow. The renewable nature of jute and its minimal ecological footprint highlight its superiority over polypropylene in terms of environmental impact and sustainability.

Strength and Durability Comparison

Jute sacks offer natural biodegradability and moderate tensile strength, making them suitable for lightweight agricultural products. Polypropylene sacks provide superior strength and resistance to moisture, chemicals, and UV exposure, resulting in higher durability for heavy-duty industrial use. The durability of polypropylene sacks outperforms jute sacks in long-term storage and harsh environmental conditions.

Cost and Economic Considerations

Jute sacks typically cost more initially than polypropylene sacks due to the natural fiber harvesting and processing methods involved, but their biodegradability and reusability offer long-term economic advantages. Polypropylene sacks are cheaper to produce and purchase, making them popular for large-scale, cost-sensitive operations despite environmental disposal costs. Evaluating total lifecycle costs, including environmental impact and potential regulatory fees, often positions jute sacks as a more economically sustainable choice over time.

Water Resistance and Moisture Protection

Jute sacks offer natural breathability but have limited water resistance, often requiring additional treatment to prevent moisture damage. Polypropylene sacks provide superior water resistance and moisture protection due to their synthetic, non-porous fibers that repel water effectively. This makes polypropylene sacks more suitable for storing and transporting goods in humid or wet environments.

Use Cases: Industry Applications of Jute and Polypropylene Sacks

Jute sacks are widely used in agriculture for storing and transporting natural products like grains, coffee, and sugar due to their biodegradability and breathability, preventing moisture buildup. Polypropylene sacks dominate in industrial sectors such as chemicals, cement, and fertilizers because of their strength, durability, and resistance to moisture and chemicals. Both materials serve packaging needs with jute preferred for eco-friendly applications and polypropylene favored for heavy-duty, moisture-resistant requirements.

Storage and Handling Efficiency

Jute sacks offer natural breathability that prevents moisture buildup, reducing the risk of mold and spoilage during storage, while polypropylene sacks are water-resistant but can trap condensation, potentially harming stored goods. Jute's robust yet biodegradable fibers provide efficient handling with less environmental impact, though polypropylene sacks are lighter and more durable under rough handling conditions. The choice between jute and polypropylene sacks depends on the specific storage environment and handling requirements, balancing natural ventilation against durability and moisture resistance.

Recycling and Disposal Options

Jute sacks are biodegradable and compostable, making them environmentally friendly in recycling and disposal compared to polypropylene sacks, which are plastic-based and require industrial recycling facilities. Polypropylene sacks often contribute to plastic pollution due to their longer decomposition time and limited recycling accessibility. Choosing jute sacks supports sustainable waste management by reducing landfill load and promoting natural fiber recycling.

Future Trends in Sack Packaging Materials

Jute sacks, known for their biodegradability and sustainability, are gaining renewed interest amid growing environmental concerns and regulatory pressures on plastic use. Polypropylene sacks remain popular due to their durability, moisture resistance, and cost-effectiveness, but innovations in bio-based polymers are challenging their dominance in the packaging industry. Future trends indicate a shift towards hybrid sacks that combine jute's eco-friendly properties with enhanced performance features, driven by increasing consumer demand for sustainable and functional packaging solutions.

Jute Sack vs Polypropylene Sack Infographic

materialdif.com

materialdif.com