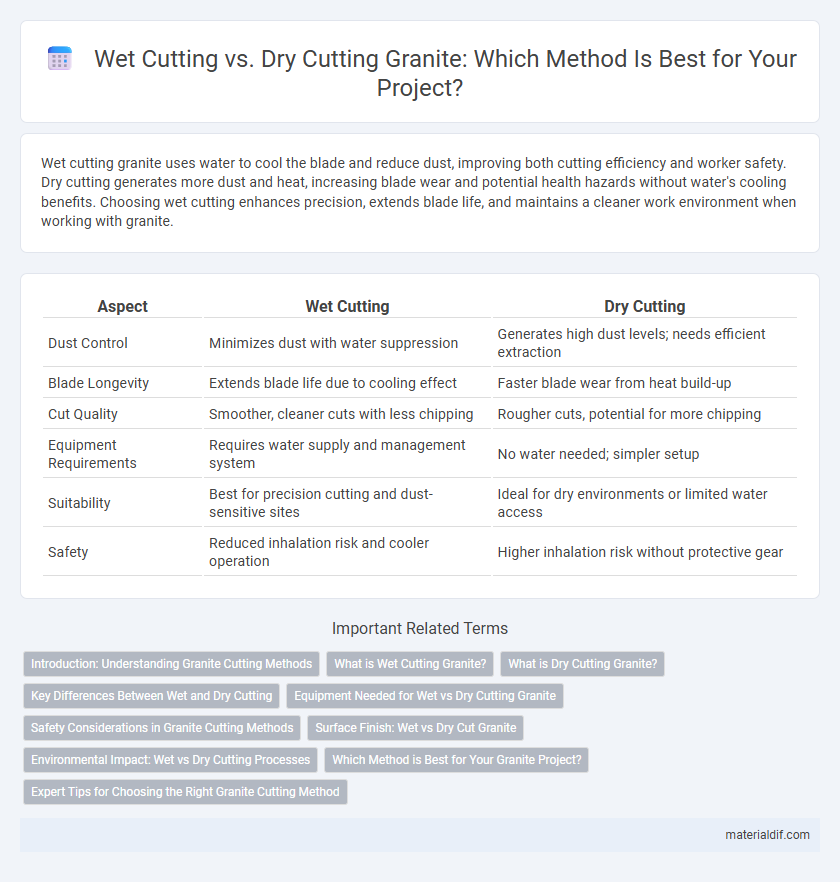

Wet cutting granite uses water to cool the blade and reduce dust, improving both cutting efficiency and worker safety. Dry cutting generates more dust and heat, increasing blade wear and potential health hazards without water's cooling benefits. Choosing wet cutting enhances precision, extends blade life, and maintains a cleaner work environment when working with granite.

Table of Comparison

| Aspect | Wet Cutting | Dry Cutting |

|---|---|---|

| Dust Control | Minimizes dust with water suppression | Generates high dust levels; needs efficient extraction |

| Blade Longevity | Extends blade life due to cooling effect | Faster blade wear from heat build-up |

| Cut Quality | Smoother, cleaner cuts with less chipping | Rougher cuts, potential for more chipping |

| Equipment Requirements | Requires water supply and management system | No water needed; simpler setup |

| Suitability | Best for precision cutting and dust-sensitive sites | Ideal for dry environments or limited water access |

| Safety | Reduced inhalation risk and cooler operation | Higher inhalation risk without protective gear |

Introduction: Understanding Granite Cutting Methods

Granite cutting methods primarily include wet cutting and dry cutting, each offering distinct advantages depending on the project requirements. Wet cutting uses water to reduce dust and cool the blade, enhancing cutting precision and blade lifespan while minimizing health hazards. Dry cutting, although faster and more portable, generates significant dust requiring protective measures to prevent respiratory issues and blade overheating.

What is Wet Cutting Granite?

Wet cutting granite involves using a diamond blade with a continuous flow of water to cool the blade and reduce dust during the cutting process. This method enhances blade life, minimizes airborne silica particles, and produces cleaner, more precise cuts on granite surfaces. Water acts as a lubricant and coolant, preventing overheating and ensuring the durability of both the equipment and the granite material.

What is Dry Cutting Granite?

Dry cutting granite involves using diamond-tipped tools to cut granite slabs without water, relying on blades designed to withstand high heat and dust generation. This method requires specialized equipment with dust extraction systems to minimize airborne particles and reduce health hazards. Dry cutting is often favored for small-scale projects or where water is impractical, though it can result in faster blade wear compared to wet cutting techniques.

Key Differences Between Wet and Dry Cutting

Wet cutting granite utilizes water to cool the blade, reduce dust, and prevent overheating, resulting in smoother cuts and longer blade life. In contrast, dry cutting generates more dust and heat, increasing the risk of blade wear and requiring specialized equipment to manage airborne particles. Choosing between wet and dry cutting depends on the specific project requirements, environmental considerations, and available tools.

Equipment Needed for Wet vs Dry Cutting Granite

Wet cutting granite requires specialized equipment like water delivery systems integrated with diamond blade saws to continuously cool the blade and reduce dust, ensuring precision and safety. Dry cutting granite uses diamond-coated blades with powerful dust extraction systems or vacuum attachments to manage airborne particles, demanding robust ventilation and personal protective equipment for operator safety. Choosing between wet and dry cutting depends on the availability and compatibility of cutting equipment with water cooling systems versus dust control technologies.

Safety Considerations in Granite Cutting Methods

Wet cutting granite significantly reduces silica dust inhalation, minimizing respiratory hazards and enhancing worker safety. Dry cutting generates high levels of airborne dust, increasing the risk of silicosis and necessitating the use of advanced dust control equipment and personal protective gear. Proper ventilation and water supply management are critical factors in maintaining a safe environment during granite cutting operations.

Surface Finish: Wet vs Dry Cut Granite

Wet cutting granite produces a smoother surface finish by reducing friction and heat, preventing microfractures and chipping. Dry cutting often results in a rougher texture with increased dust and higher risk of surface imperfections due to overheating. Using water during the cutting process enhances the overall quality and durability of the granite surface.

Environmental Impact: Wet vs Dry Cutting Processes

Wet cutting granite reduces airborne dust particles significantly, minimizing respiratory health risks and environmental pollution compared to dry cutting methods. The water used in wet cutting captures dust at the source, preventing it from dispersing into the air and contaminating surrounding ecosystems. Dry cutting generates large amounts of silica dust that can contribute to air quality degradation and requires additional measures for dust control and worker protection.

Which Method is Best for Your Granite Project?

Wet cutting granite uses water to reduce dust and cool the blade, enhancing precision and extending tool life, making it ideal for indoor or sensitive environments. Dry cutting produces more dust and heat, requiring dust control measures, but offers greater portability and faster setup for outdoor projects. Selecting the best method depends on the project environment, desired finish quality, and available equipment.

Expert Tips for Choosing the Right Granite Cutting Method

Expert tips for choosing between wet cutting and dry cutting granite emphasize the importance of project type and tool durability. Wet cutting reduces dust and extends blade life by cooling the blade and minimizing silica dust exposure, which is crucial for indoor or precision work. Dry cutting offers faster cutting speeds and portability but requires proper ventilation and protective gear to handle airborne dust safely.

Wet Cutting vs Dry Cutting (Granite) Infographic

materialdif.com

materialdif.com