Waterjet cutting offers precise, clean cuts on granite without causing heat damage, preserving the stone's natural integrity. Diamond blade cutting, while effective for thicker granite slabs, generates heat that may lead to micro-cracks and material stress. Choosing waterjet cutting ensures smoother edges and reduced risk of fractures compared to the mechanical pressure and heat involved in diamond blade cutting.

Table of Comparison

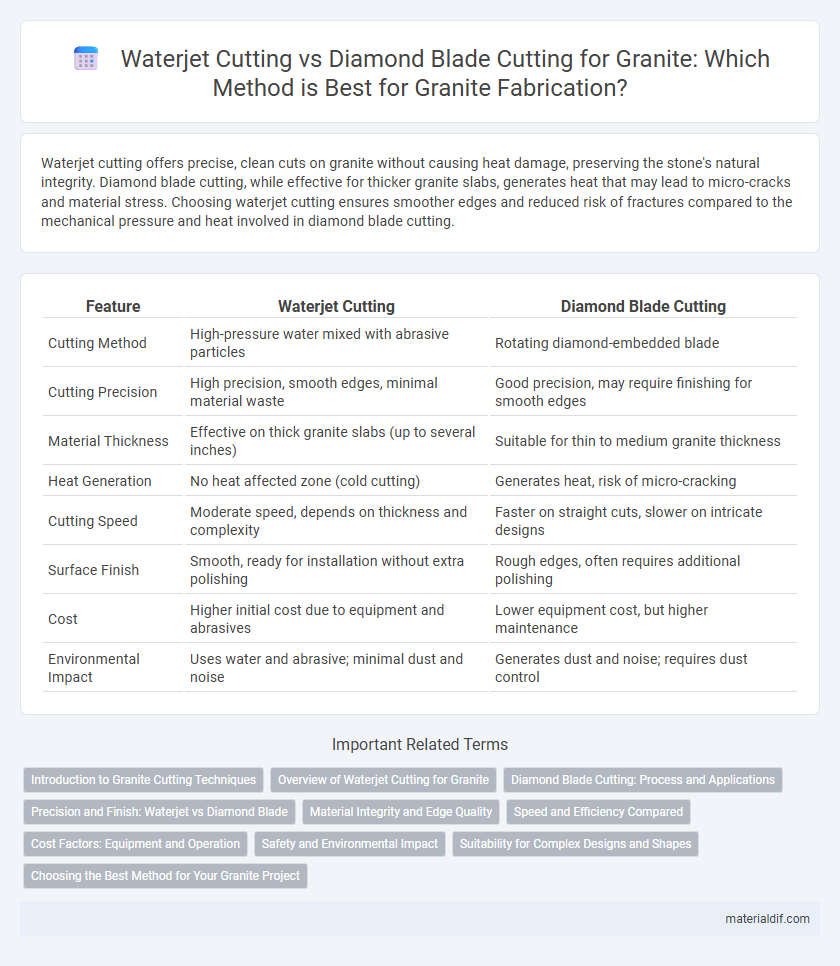

| Feature | Waterjet Cutting | Diamond Blade Cutting |

|---|---|---|

| Cutting Method | High-pressure water mixed with abrasive particles | Rotating diamond-embedded blade |

| Cutting Precision | High precision, smooth edges, minimal material waste | Good precision, may require finishing for smooth edges |

| Material Thickness | Effective on thick granite slabs (up to several inches) | Suitable for thin to medium granite thickness |

| Heat Generation | No heat affected zone (cold cutting) | Generates heat, risk of micro-cracking |

| Cutting Speed | Moderate speed, depends on thickness and complexity | Faster on straight cuts, slower on intricate designs |

| Surface Finish | Smooth, ready for installation without extra polishing | Rough edges, often requires additional polishing |

| Cost | Higher initial cost due to equipment and abrasives | Lower equipment cost, but higher maintenance |

| Environmental Impact | Uses water and abrasive; minimal dust and noise | Generates dust and noise; requires dust control |

Introduction to Granite Cutting Techniques

Granite cutting techniques primarily involve waterjet cutting and diamond blade cutting, each optimized for precision and efficiency. Waterjet cutting uses a high-pressure stream of water mixed with abrasive particles to slice through granite with minimal heat generation, preserving the stone's integrity. Diamond blade cutting employs industrial-grade diamond-tipped blades to grind through granite, offering faster cuts but generating heat that requires cooling to prevent stone damage.

Overview of Waterjet Cutting for Granite

Waterjet cutting for granite utilizes a high-pressure stream of water mixed with abrasive particles to precisely slice through the stone without generating heat, preserving the material's natural integrity. This method offers clean edges, minimal material waste, and the ability to cut intricate shapes and patterns with superior accuracy compared to traditional diamond blade cutting. Waterjet technology is highly effective for thick granite slabs, providing enhanced versatility and reducing the risk of micro-cracking or surface damage.

Diamond Blade Cutting: Process and Applications

Diamond blade cutting for granite involves a rotating blade embedded with industrial-grade diamond particles that efficiently slices through dense stone with precision. This method is ideal for creating intricate shapes, straight cuts, and detailed edge profiles in granite countertops, tiles, and architectural elements. The process ensures minimal chipping and a smooth finish, making it a preferred choice for both large-scale construction and custom fabrication projects.

Precision and Finish: Waterjet vs Diamond Blade

Waterjet cutting offers superior precision in granite processing due to its ability to follow intricate designs with minimal material loss and no heat-affected zones, resulting in smooth, clean edges. Diamond blade cutting provides reliable performance but may cause micro-cracks and a rougher finish because of the mechanical abrasion and heat generated during the process. For high-precision projects requiring detailed patterns and flawless finishes, waterjet cutting is generally the preferred method over diamond blade cutting.

Material Integrity and Edge Quality

Waterjet cutting preserves the material integrity of granite by using high-pressure water mixed with abrasive particles, minimizing thermal stress and preventing microcracks. Diamond blade cutting involves rotary grinding, which can generate heat that risks minor edge chipping and micro-fractures in the granite. Edge quality in waterjet cutting typically exhibits smoother, more precise finishes with reduced risk of edge delamination compared to the slightly rougher edges produced by diamond blade methods.

Speed and Efficiency Compared

Waterjet cutting offers faster processing speeds for intricate granite designs due to its high-pressure abrasive stream, reducing material waste and minimizing heat-induced damage. Diamond blade cutting, while effective for straight cuts, generally operates slower with increased blade wear and requires frequent blade replacements, impacting overall efficiency. Choosing waterjet cutting improves operational throughput and precision when working with complex granite patterns.

Cost Factors: Equipment and Operation

Waterjet cutting for granite involves high initial equipment costs due to specialized pumps and abrasive materials, while diamond blade cutting requires substantial investment in diamond-tipped blades and saw machinery. Operational expenses for waterjet cutting include abrasive replenishment and higher power consumption, whereas diamond blade cutting demands frequent blade replacements and periodic saw maintenance. Choosing between the two methods depends on balancing equipment depreciation, consumable usage, and labor costs specific to granite fabrication projects.

Safety and Environmental Impact

Waterjet cutting granite offers superior safety by eliminating dust and reducing the risk of blade breakage compared to diamond blade cutting, which generates silica dust and requires sharp, high-speed blades that pose inhalation and injury hazards. Environmentally, waterjet cutting minimizes airborne particulate pollution and uses recyclable water, whereas diamond blade cutting produces significant silica dust and blade wear waste that demands careful disposal to prevent environmental contamination. Opting for waterjet technology enhances worker safety while reducing the ecological footprint associated with granite fabrication.

Suitability for Complex Designs and Shapes

Waterjet cutting excels in creating intricate and complex granite designs due to its precise, computer-controlled high-pressure water stream that can effortlessly produce detailed curves and shapes without causing material stress. Diamond blade cutting, while effective for straight cuts and simple shapes, struggles with intricate patterns and can leave rough edges requiring extensive finishing. For elaborate granite designs demanding high accuracy and smooth outcomes, waterjet cutting offers superior suitability and versatility.

Choosing the Best Method for Your Granite Project

Waterjet cutting offers precise, clean cuts on granite without heat damage, making it ideal for intricate designs and preserving the stone's integrity. Diamond blade cutting provides faster, more cost-effective results for larger slabs or straight cuts but may cause minor chipping or surface fractures. Selecting the best method depends on the project's complexity, desired finish quality, and budget constraints.

Waterjet Cutting vs Diamond Blade Cutting (for Granite) Infographic

materialdif.com

materialdif.com