Electroformed gold offers a lightweight and highly detailed design by building up layers of gold through an electrochemical process, resulting in intricate textures perfect for fine jewelry. Cast gold involves melting and pouring gold into molds, producing solid, durable pieces with a traditional finish and weight. Choosing between electroformed and cast gold depends on whether the priority is delicate craftsmanship or robust strength in the final product.

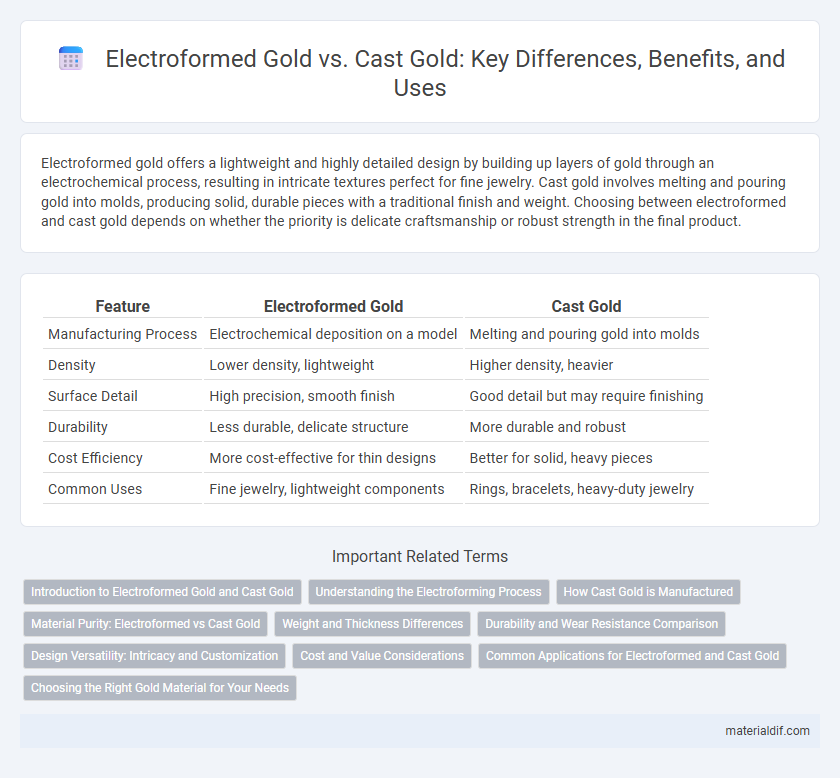

Table of Comparison

| Feature | Electroformed Gold | Cast Gold |

|---|---|---|

| Manufacturing Process | Electrochemical deposition on a model | Melting and pouring gold into molds |

| Density | Lower density, lightweight | Higher density, heavier |

| Surface Detail | High precision, smooth finish | Good detail but may require finishing |

| Durability | Less durable, delicate structure | More durable and robust |

| Cost Efficiency | More cost-effective for thin designs | Better for solid, heavy pieces |

| Common Uses | Fine jewelry, lightweight components | Rings, bracelets, heavy-duty jewelry |

Introduction to Electroformed Gold and Cast Gold

Electroformed gold is created by depositing pure gold onto a mold through an electrochemical process, resulting in lightweight yet durable jewelry with intricate detailing. Cast gold involves melting gold into a liquid state before pouring it into molds, producing solid pieces with a traditional, dense structure favored for classic jewelry designs. Both methods enhance gold's versatility, with electroforming offering precision and reduced weight, while casting ensures robust, long-lasting artifacts.

Understanding the Electroforming Process

Electroformed gold is created through an electrochemical process where gold ions are deposited onto a conductive surface, allowing for precise, lightweight designs with intricate details. Cast gold involves melting gold and pouring it into molds, resulting in denser, heavier pieces less suited for fine detailing. Understanding electroforming highlights its advantages in producing delicate jewelry with superior surface quality and reduced metal waste.

How Cast Gold is Manufactured

Cast gold is manufactured through a precise process involving melting gold alloys and pouring the molten metal into detailed molds to achieve intricate designs. This method enables consistent replication of complex shapes with high durability and a smooth finish. The investment casting technique ensures precise control over the gold's composition and structural integrity for fine jewelry production.

Material Purity: Electroformed vs Cast Gold

Electroformed gold boasts higher material purity, often exceeding 99.9% pure gold due to the precise deposition process that minimizes alloy impurities. Cast gold typically contains a lower purity level, as it involves melting and mixing gold with other metals to enhance strength and durability. The superior purity of electroformed gold results in a brighter finish and increased resistance to tarnishing compared to cast gold.

Weight and Thickness Differences

Electroformed gold is significantly lighter than cast gold due to its thin, hollow structure created by electrodeposition, often resulting in pieces weighing less than half of cast gold equivalents. Cast gold, produced by pouring molten gold into molds, tends to be denser and thicker, providing a more substantial weight and durability. The thickness of electroformed gold can be meticulously controlled during the electroplating process, typically ranging from a few microns to a fraction of a millimeter, whereas cast gold thickness is determined by mold design and can be much bulkier.

Durability and Wear Resistance Comparison

Electroformed gold features a thin, precise layer built up through electrodeposition, offering excellent surface detail but lower overall durability compared to cast gold. Cast gold, created by melting and pouring molten gold into molds, provides superior wear resistance and structural strength, making it ideal for heavy-use jewelry. The denser composition of cast gold withstands daily wear and tear more effectively than the thinner electroformed layer, which can be prone to chipping or wearing away over time.

Design Versatility: Intricacy and Customization

Electroformed gold offers exceptional design versatility, enabling the creation of intricate, lightweight structures with fine details that traditional casting methods struggle to achieve. Cast gold, while robust and suitable for classic designs, often limits customization due to mold constraints and heavier, solid forms. The electroforming process allows jewelers to push boundaries in complexity and personalization, producing unique, delicate pieces with greater precision and minimal material waste.

Cost and Value Considerations

Electroformed gold offers a lightweight, cost-effective alternative to traditional cast gold by using a plating process that requires less raw material, significantly reducing production expenses. Cast gold, made by melting and molding solid gold, holds higher intrinsic value due to its density and durability, appealing to consumers prioritizing long-term investment. Choosing between electroformed and cast gold depends on balancing budget constraints with desired quality and resale value.

Common Applications for Electroformed and Cast Gold

Electroformed gold is predominantly used in intricate jewelry designs and lightweight, fine details due to its precise layering and minimal material waste. Cast gold is favored for making durable, solid pieces like rings, bracelets, and sculptures, where strength and mass are essential. Jewelry manufacturers choose electroforming for delicate, hollow components, while casting suits heavy, robust items requiring structural integrity.

Choosing the Right Gold Material for Your Needs

Electroformed gold offers lightweight durability with intricate detailing, making it ideal for delicate designs and costume jewelry, while cast gold boasts superior strength and density, suitable for investment pieces and everyday wear. Selecting between electroformed and cast gold depends on the desired balance of weight, durability, and craftsmanship, with 14K or 18K purity options influencing both price and longevity. Understanding the specific application ensures the best match for personal style and functional requirements.

Electroformed Gold vs Cast Gold Infographic

materialdif.com

materialdif.com