Indigo dye is prized for its vibrant, deep blue color and natural fading properties, making it a popular choice for denim pet products seeking a classic, vintage look. Sulfur dye offers a broader color range, including blacks and browns, with excellent wash fastness and durability, ideal for long-lasting denim pet accessories. Choosing between indigo and sulfur dye depends on the desired aesthetic and performance, balancing tradition with practical wear resistance.

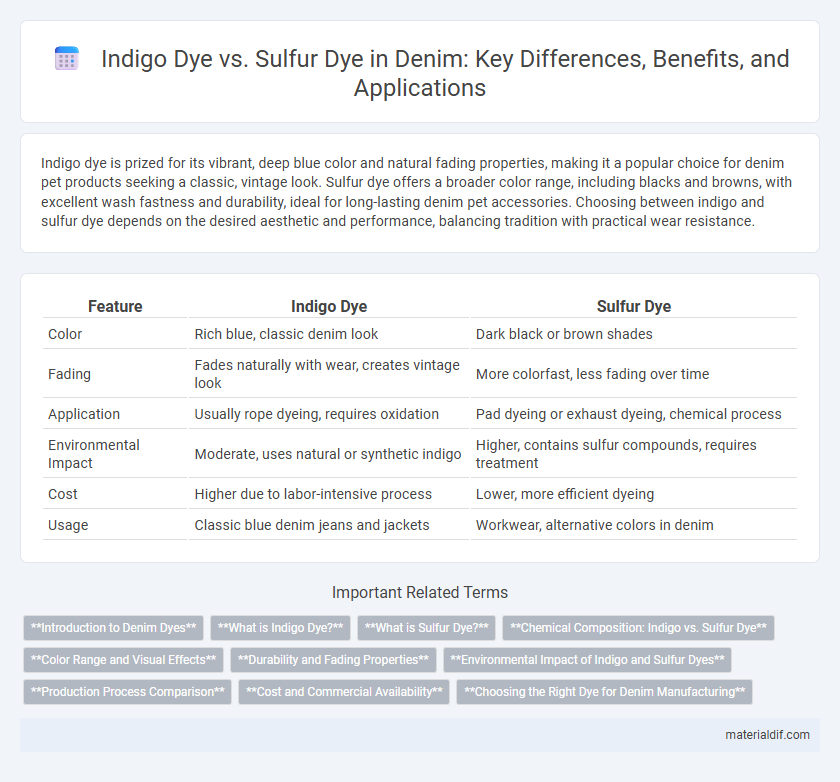

Table of Comparison

| Feature | Indigo Dye | Sulfur Dye |

|---|---|---|

| Color | Rich blue, classic denim look | Dark black or brown shades |

| Fading | Fades naturally with wear, creates vintage look | More colorfast, less fading over time |

| Application | Usually rope dyeing, requires oxidation | Pad dyeing or exhaust dyeing, chemical process |

| Environmental Impact | Moderate, uses natural or synthetic indigo | Higher, contains sulfur compounds, requires treatment |

| Cost | Higher due to labor-intensive process | Lower, more efficient dyeing |

| Usage | Classic blue denim jeans and jackets | Workwear, alternative colors in denim |

Introduction to Denim Dyes

Indigo dye, traditionally derived from the indigofera plant, is renowned for its deep blue hue and fading characteristics that give denim its classic worn-in look. Sulfur dye, a synthetic alternative, offers a broader color range with excellent colorfastness and cost-effectiveness but lacks the unique fading properties of indigo. Both dyes play crucial roles in denim manufacturing, influencing fabric aesthetics, durability, and consumer preferences.

What is Indigo Dye?

Indigo dye is a natural or synthetic dye known for its deep blue color, primarily used in denim production. It originates from the plant Indigofera tinctoria or is chemically synthesized to create a vibrant, long-lasting hue that fades uniquely with wear. Indigo dye penetrates denim fibers only on the surface, enabling the characteristic fading effect that defines classic blue jeans.

What is Sulfur Dye?

Sulfur dye is a type of dye commonly used in denim manufacturing to achieve darker and more matte finishes compared to indigo dye. Unlike indigo, which produces the classic blue color through a reduction-oxidation process that fades uniquely over time, sulfur dye creates deeper blacks and browns with excellent colorfastness and resistance to washing. This dyeing method provides a cost-effective alternative for durable denim garments with distinct aesthetic qualities.

Chemical Composition: Indigo vs. Sulfur Dye

Indigo dye is primarily composed of indican molecules that oxidize to form insoluble indigotin, giving denim its characteristic deep blue color, whereas sulfur dyes are organic compounds containing sulfur atoms that bind chemically to fabric fibers, producing a range of darker shades from black to brown. Indigo's chemical structure results in surface dyeing that fades uniquely with wear, while sulfur dyes chemically bond within the fiber, offering enhanced colorfastness and resistance to washing. The molecular differences between indigo's planar, conjugated system and the sulfur dye's thiol or disulfide groups dictate their distinct application methods and durability in denim textiles.

Color Range and Visual Effects

Indigo dye provides a distinctive deep blue hue with natural fading characteristics that enhance denim's vintage appeal and unique whiskering over time. Sulfur dye offers a broader color range, from black to brown and olive tones, enabling diverse visual effects that depend on the fiber's interaction with the dye. Combining these dyes allows denim manufacturers to achieve varied aesthetics, balancing classic blue shades with richer, more textured finishes.

Durability and Fading Properties

Indigo dye is renowned for its exceptional fading properties, creating the classic worn-in look as it fades gradually with wear and washing, which enhances denim's character over time. Sulfur dye offers superior durability and colorfastness, maintaining a more consistent hue that resists fading even under frequent use and exposure to sunlight. Denim treated with indigo dye typically develops unique fade patterns that highlight fabric texture, while sulfur-dyed denim retains a deeper, more uniform color for extended longevity.

Environmental Impact of Indigo and Sulfur Dyes

Indigo dye, derived from plant-based sources or synthetic compounds, generally exhibits lower environmental toxicity and better biodegradability compared to sulfur dyes, which contain sulfur compounds that can release harmful hydrogen sulfide during production and disposal. The wastewater from indigo dyeing processes tends to have a reduced chemical oxygen demand (COD) and less toxic effluent, making it more eco-friendly in large-scale denim manufacturing. Conversely, sulfur dyes often contribute to soil and water pollution due to their high levels of sulfides and heavy metals, raising concerns about long-term environmental sustainability in denim production.

Production Process Comparison

Indigo dyeing involves a complex reduction-oxidation process where the fabric is repeatedly dipped in indigo vat and exposed to air, creating a deep blue color that develops with each dip. In contrast, sulfur dyeing uses chemical reactions with sulfur-based compounds that fix the dye directly onto the fiber, generally offering faster processing and a broader range of colors including black and browns. The indigo process is labor-intensive and environmentally challenging due to the use of strong reducing agents, whereas sulfur dyeing, while quicker, requires careful handling of sulfur compounds to minimize environmental impact.

Cost and Commercial Availability

Indigo dye is traditionally more expensive due to the complex fermentation and extraction process but remains widely available through established suppliers in the denim industry. Sulfur dye offers a cost-effective alternative with simpler production methods, making it financially attractive for mass-market denim manufacturers. Commercial availability of sulfur dyes has grown significantly, driven by demand for diverse color options and lower price points in global denim markets.

Choosing the Right Dye for Denim Manufacturing

Indigo dye remains the classic choice for denim manufacturing, offering vibrant blue hues and excellent fade characteristics that develop unique wear patterns over time. Sulfur dye provides a versatile palette including black and other dark shades, with superior colorfastness and resistance to fading in comparison to indigo. Choosing the right dye depends on desired aesthetic effects, durability requirements, and specific garment wash processes used in production.

Indigo dye vs sulfur dye Infographic

materialdif.com

materialdif.com