Velvet flocking creates a soft, raised texture by applying short fibers to a surface, offering a tactile dimension ideal for luxurious decor and fashion. Velvet printing, on the other hand, produces a smooth, visually rich finish by printing velvet patterns directly onto fabric, providing detailed designs without altering the fabric's texture. Choosing between velvet flocking and velvet printing depends on the desired texture and visual effect for your project.

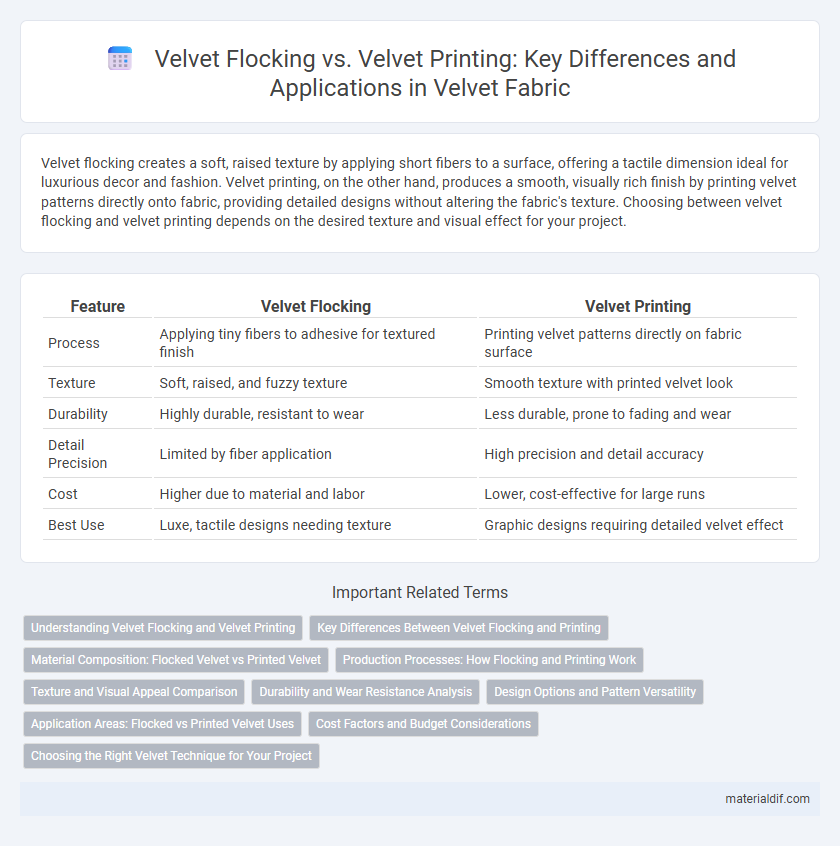

Table of Comparison

| Feature | Velvet Flocking | Velvet Printing |

|---|---|---|

| Process | Applying tiny fibers to adhesive for textured finish | Printing velvet patterns directly on fabric surface |

| Texture | Soft, raised, and fuzzy texture | Smooth texture with printed velvet look |

| Durability | Highly durable, resistant to wear | Less durable, prone to fading and wear |

| Detail Precision | Limited by fiber application | High precision and detail accuracy |

| Cost | Higher due to material and labor | Lower, cost-effective for large runs |

| Best Use | Luxe, tactile designs needing texture | Graphic designs requiring detailed velvet effect |

Understanding Velvet Flocking and Velvet Printing

Velvet flocking involves applying tiny fibers to a surface using adhesive, creating a soft, textured, and velvety finish ideal for adding depth to fabric and packaging. Velvet printing, on the other hand, uses specialized inks or powder that produce a raised, tactile velvet-like effect on materials through a heat or curing process. Understanding these techniques helps in selecting the best method for achieving either a plush texture with flocking or a smooth velvet appearance with printing based on design requirements.

Key Differences Between Velvet Flocking and Printing

Velvet flocking involves applying fine fibers to a surface, creating a soft, textured finish with a raised, velvety feel, while velvet printing uses specialized ink to reproduce velvet-like patterns with a smooth, flat texture. Flocking offers a three-dimensional tactile experience with enhanced durability and a plush appearance, whereas printing provides detailed designs with vibrant colors but lacks the tangible softness of flocked velvet. The choice between flocking and printing depends on desired texture, visual effect, and application durability in textile or product design.

Material Composition: Flocked Velvet vs Printed Velvet

Flocked velvet features a dense layer of fine fibers adhered to a fabric base, creating a soft, raised texture with a luxurious feel distinguished by its tactile depth. Printed velvet, in contrast, relies on dye or ink applied directly onto the velvet's surface, resulting in vibrant patterns without altering the fabric's smooth, plush nap. Material composition in flocked velvet emphasizes the fiber density and adhesive quality, while printed velvet prioritizes pigment saturation and fabric smoothness.

Production Processes: How Flocking and Printing Work

Velvet flocking involves applying tiny fiber particles onto a substrate using adhesive, creating a soft, textured surface through an electrostatic or mechanical process. Velvet printing uses specialized inks and rollers or screens to transfer plush, velvet-like patterns onto fabric, relying on heat or curing to set the design. Flocking produces a raised, tactile finish, while velvet printing emphasizes detailed patterns with a flat, smooth velvet effect.

Texture and Visual Appeal Comparison

Velvet flocking involves applying tiny fiber particles to a surface, creating a soft, tactile texture that mimics the plush depth of natural velvet. Velvet printing, on the other hand, uses specialized inks to simulate the appearance of velvet with a smooth finish, prioritizing visual richness over touch. The flocking technique offers a more authentic velvet feel, while velvet printing excels in detailed, vibrant designs with less texture variance.

Durability and Wear Resistance Analysis

Velvet flocking offers superior durability due to its densely packed fibers that resist wear and maintain texture integrity over time, making it ideal for high-traffic applications. Velvet printing, while allowing intricate designs and color variation, tends to have lower wear resistance as the printed surface can fade or peel with prolonged use. Choosing between velvet flocking and velvet printing depends on balancing aesthetic preferences with the need for long-lasting fabric performance.

Design Options and Pattern Versatility

Velvet flocking offers rich texture with three-dimensional depth, ideal for intricate patterns and tactile designs that enhance visual luxury. Velvet printing allows for precise, multicolor patterns with extensive detail and flexibility, supporting complex motifs and varied color schemes. Design options with flocking excel in creating raised effects, while printing prioritizes versatility in pattern complexity and color vibrancy.

Application Areas: Flocked vs Printed Velvet Uses

Velvet flocking is commonly applied in automotive upholstery, luxury packaging, and decorative textiles, offering a textured, tactile surface ideal for high-end fashion accessories and interior design elements. Printed velvet, featuring detailed patterns and vibrant colors, is predominantly used in apparel, home decor fabrics, and theatrical costumes where intricate visual designs enhance aesthetic appeal. Both techniques cater to distinct markets, with flocking emphasizing texture and print focusing on graphic richness in velvet products.

Cost Factors and Budget Considerations

Velvet flocking generally incurs higher costs due to the specialized equipment and materials required, making it less suitable for tight budgets. Velvet printing offers a more cost-effective option by using traditional printing techniques that reduce production time and material expenses. Budget considerations should weigh the desired texture and durability against these cost differences to determine the best method for each project.

Choosing the Right Velvet Technique for Your Project

Velvet flocking creates a textured, three-dimensional surface by applying tiny fibers onto adhesive, offering a soft, plush feel ideal for luxury packaging and upholstery. Velvet printing, on the other hand, provides a smooth, visually rich appearance by printing velvet-like patterns directly onto fabric or paper, suitable for fashion and decorative applications. Selecting the right velvet technique depends on whether tactile depth or visual detail is prioritized in your project.

Velvet Flocking vs Velvet Printing Infographic

materialdif.com

materialdif.com