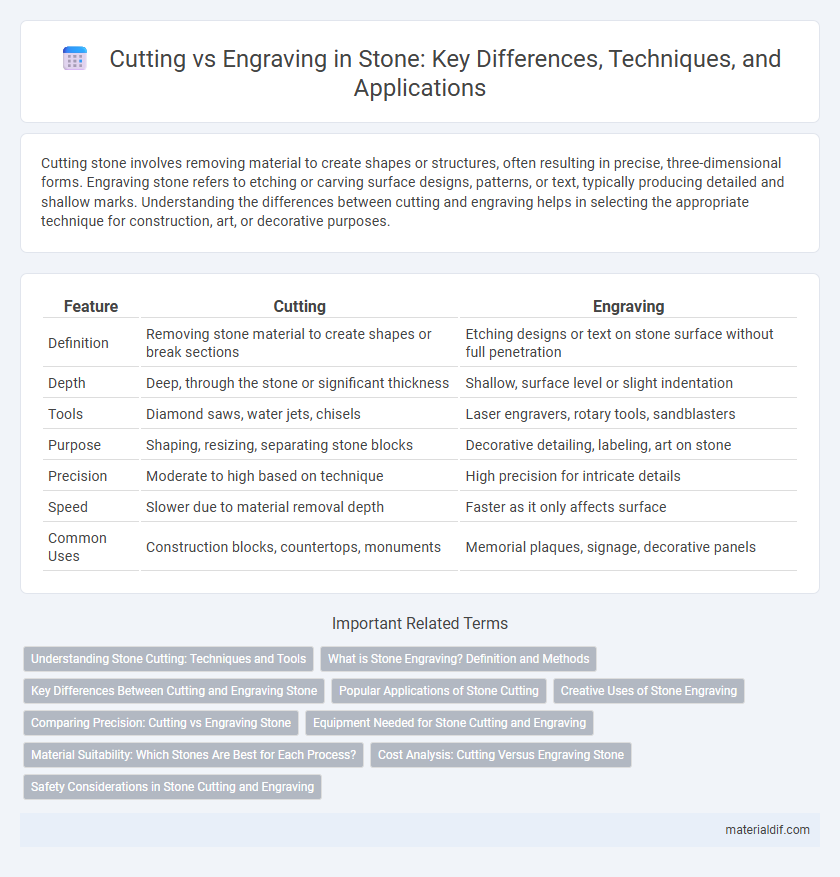

Cutting stone involves removing material to create shapes or structures, often resulting in precise, three-dimensional forms. Engraving stone refers to etching or carving surface designs, patterns, or text, typically producing detailed and shallow marks. Understanding the differences between cutting and engraving helps in selecting the appropriate technique for construction, art, or decorative purposes.

Table of Comparison

| Feature | Cutting | Engraving |

|---|---|---|

| Definition | Removing stone material to create shapes or break sections | Etching designs or text on stone surface without full penetration |

| Depth | Deep, through the stone or significant thickness | Shallow, surface level or slight indentation |

| Tools | Diamond saws, water jets, chisels | Laser engravers, rotary tools, sandblasters |

| Purpose | Shaping, resizing, separating stone blocks | Decorative detailing, labeling, art on stone |

| Precision | Moderate to high based on technique | High precision for intricate details |

| Speed | Slower due to material removal depth | Faster as it only affects surface |

| Common Uses | Construction blocks, countertops, monuments | Memorial plaques, signage, decorative panels |

Understanding Stone Cutting: Techniques and Tools

Stone cutting involves shaping and resizing stone blocks using tools such as diamond-tipped saws, chisels, and wire saws, emphasizing precision in breaking the stone along its natural fissures. In contrast, engraving focuses on detailed surface work to create decorative patterns or inscriptions through methods like laser engraving or hand carving with rotary tools. Mastery of cutting techniques requires knowledge of stone hardness, grain orientation, and appropriate tool selection to achieve clean cuts without damaging the stone's integrity.

What is Stone Engraving? Definition and Methods

Stone engraving involves incising designs, patterns, or text into the surface of stone using tools like chisels, rotary engravers, or laser technology. Traditional methods include hand engraving with metal tools for detailed craftsmanship, while modern techniques utilize CNC machines and laser engravers for precision and efficiency. This process enhances the stone's aesthetic and functional value, commonly seen in monuments, architectural features, and decorative art.

Key Differences Between Cutting and Engraving Stone

Cutting stone involves removing large portions of material to shape or separate pieces, often using saws or blades optimized for hardness and durability. Engraving stone focuses on creating detailed surface designs or text by etching or carving shallow grooves with precision tools like rotary engravers or laser cutters. The main difference lies in cutting's emphasis on structural alteration and separation, while engraving prioritizes aesthetic surface modifications without compromising the stone's integrity.

Popular Applications of Stone Cutting

Stone cutting is widely used in construction for creating precise blocks and slabs essential for building facades, countertops, and flooring. Popular applications include producing marble tiles, granite countertops, and limestone pavers, where exact dimensions and smooth finishes are critical. Advanced water jet and diamond blade cutting technologies enhance the efficiency and accuracy of these stone fabrication processes.

Creative Uses of Stone Engraving

Stone engraving transforms natural surfaces into detailed artworks, offering creative uses such as personalized memorials, intricate decorative patterns, and custom signage. Unlike cutting, which removes large sections of stone, engraving carves precise lines and textures, enabling artists to produce fine lettering and elaborate imagery. This technique enhances both the aesthetic and functional value of stone by combining durability with artistic expression.

Comparing Precision: Cutting vs Engraving Stone

Cutting stone typically involves removing large sections with tools like diamond blades or water jets, offering high precision in shaping and resizing materials. Engraving stone uses fine tools such as laser etching or rotary bits to create detailed designs with superior control over intricate patterns and depth variations. While cutting excels in structural modifications, engraving provides unmatched precision for decorative and detailed artistic work.

Equipment Needed for Stone Cutting and Engraving

Stone cutting requires heavy-duty equipment such as diamond-tipped saw blades, water jets, and CNC stone cutting machines designed to handle the hardness and density of materials like granite and marble. Engraving stone involves more precise tools including rotary engravers, pneumatic chisels, or laser engravers that can create detailed patterns without compromising the stone's structural integrity. Both processes rely on specialized machinery optimized for their specific tasks to achieve high-quality finishes on natural stone surfaces.

Material Suitability: Which Stones Are Best for Each Process?

Granite and marble excel in cutting due to their density and durability, allowing precise shaping without excessive wear on tools. Softer stones like limestone and sandstone are more suitable for engraving, as their porous textures hold intricate designs clearly without cracking. Quartzite, with its hardness and fine grain, serves well in both cutting and engraving, offering versatility across stoneworking applications.

Cost Analysis: Cutting Versus Engraving Stone

Cutting stone typically incurs higher costs due to the need for specialized tools and increased labor time, especially when dealing with thicker or harder materials like granite or marble. Engraving, on the other hand, is often more cost-effective as it requires less material removal and allows for faster production with precision laser or CNC machines. Careful consideration of the project scale, stone type, and desired detail level is essential for accurate cost analysis between cutting and engraving processes.

Safety Considerations in Stone Cutting and Engraving

Safety considerations in stone cutting and engraving are critical to prevent injuries and ensure a safe working environment. Proper protective gear, such as goggles, gloves, and dust masks, is essential to shield against sharp stone fragments and harmful silica dust. Employing well-maintained tools and ventilation systems reduces the risk of accidents and long-term respiratory issues.

Cutting vs Engraving Infographic

materialdif.com

materialdif.com