Silver clad components feature a thick, durable layer of silver bonded to a base metal, offering superior corrosion resistance and excellent conductivity ideal for electrical applications. Silver overlay, however, involves a thinner silver coating fused onto the substrate, providing decorative appeal and moderate protection but less durability under heavy wear. Choosing between silver clad and silver overlay depends on the balance between functional longevity and aesthetic requirements.

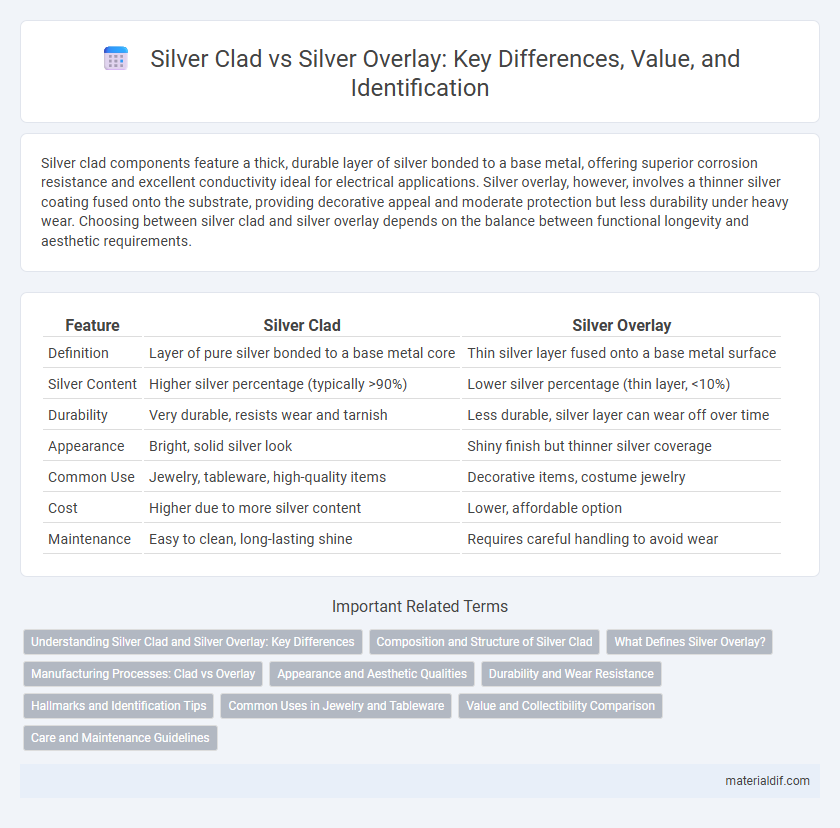

Table of Comparison

| Feature | Silver Clad | Silver Overlay |

|---|---|---|

| Definition | Layer of pure silver bonded to a base metal core | Thin silver layer fused onto a base metal surface |

| Silver Content | Higher silver percentage (typically >90%) | Lower silver percentage (thin layer, <10%) |

| Durability | Very durable, resists wear and tarnish | Less durable, silver layer can wear off over time |

| Appearance | Bright, solid silver look | Shiny finish but thinner silver coverage |

| Common Use | Jewelry, tableware, high-quality items | Decorative items, costume jewelry |

| Cost | Higher due to more silver content | Lower, affordable option |

| Maintenance | Easy to clean, long-lasting shine | Requires careful handling to avoid wear |

Understanding Silver Clad and Silver Overlay: Key Differences

Silver clad refers to a base metal coated with a thick layer of silver, offering enhanced durability and corrosion resistance ideal for industrial applications and jewelry. Silver overlay involves applying a thinner, decorative silver layer on top of a non-metal substrate, commonly used in ornamental pieces and tableware for aesthetic appeal. The primary difference lies in the thickness and purpose of the silver layer, with clad providing structural strength and overlay emphasizing decorative finish.

Composition and Structure of Silver Clad

Silver clad refers to a base metal, such as copper or nickel, coated with a thick layer of high-purity silver, typically through mechanical bonding or electroplating, resulting in a durable and conductive material. The structure of silver clad materials involves a solid substrate core enveloped by a continuous silver layer, ensuring enhanced corrosion resistance and electrical performance. This composition differentiates it from silver overlay, which generally features a thinner, decorative silver layer applied on various base metals, focusing more on aesthetics than structural integrity.

What Defines Silver Overlay?

Silver overlay refers to a decorative technique where a thin layer of pure silver is meticulously applied over a base material such as glass or ceramic, creating a distinct metallic finish. This process involves bonding silver sheets or foils onto the surface, often combined with intricate engraving or etching to enhance aesthetic appeal and texture. Silver overlay is defined by its durability, reflective quality, and the seamless integration of silver that contrasts with the underlying substrate.

Manufacturing Processes: Clad vs Overlay

Silver clad involves bonding a layer of pure silver onto a base metal through high-pressure bonding or rolling, creating a durable, thick layer that offers enhanced conductivity and corrosion resistance. Silver overlay is produced by applying a thin layer of silver onto a substrate using electroplating or fusion techniques, resulting in a decorative finish with less silver content. Manufacturing silver clad requires more extensive materials and processes, leading to higher durability, while silver overlay prioritizes aesthetic appeal with cost-efficiency.

Appearance and Aesthetic Qualities

Silver clad items feature a thicker layer of silver bonded to a base metal, resulting in a more durable and long-lasting finish with a consistent, bright luster that resists tarnishing better than silver overlay. Silver overlay involves a thinner silver coating applied to the surface, producing a delicate, shiny appearance but with less durability and a higher tendency to wear off over time. Both techniques offer distinctive aesthetic qualities: silver clad provides a robust, polished look ideal for everyday use, while silver overlay delivers a more refined, decorative appeal suitable for occasional display.

Durability and Wear Resistance

Silver clad jewelry consists of a base metal coated with a thick layer of silver, providing enhanced durability and superior wear resistance compared to silver overlay items, which have a much thinner silver layer applied through plating. The thicker silver layer in silver clad pieces withstands tarnishing and scratches better, extending the lifespan of the jewelry under regular use. Silver overlay, while visually similar at first, tends to wear off more quickly due to its delicate coating, making it less suitable for everyday wear and more prone to fading.

Hallmarks and Identification Tips

Silver clad items feature a thick layer of silver bonded to a base metal, often lacking official hallmarks, whereas silver overlay consists of a thinner silver layer more easily worn away and may have partial markings. Authentic silver hallmarks such as "925," "Sterling," or the maker's mark help identify genuine silver pieces, while absence or partial hallmarks often indicate silver clad or overlay. Testing techniques like magnetism tests, acid tests, or visual inspection of hallmark clarity and wear patterns assist in distinguishing between silver clad and silver overlay.

Common Uses in Jewelry and Tableware

Silver clad items feature a thicker layer of silver bonded to a base metal, making them durable and ideal for everyday jewelry like rings and bracelets that require long-lasting shine. Silver overlay involves a thinner silver coating, often used in decorative tableware such as trays, bowls, and serving utensils to provide an elegant appearance without the cost of solid silver. Both techniques offer affordable ways to achieve the aesthetic of silver, with clad preferred for high-wear items and overlay favored for ornamental pieces.

Value and Collectibility Comparison

Silver Clad items contain a thicker layer of genuine silver fused to a base metal, offering greater intrinsic value and durability compared to Silver Overlay, which uses a thinner silver coating. Collectors often prefer Silver Clad for its longer-lasting finish and higher silver content, enhancing both aesthetic appeal and resale value. Silver Overlay pieces, while visually attractive, typically hold less value due to their minimal silver layer and increased susceptibility to wear.

Care and Maintenance Guidelines

Silver clad items require gentle cleaning with mild soap and a soft cloth to avoid wearing down the thin silver layer, while silver overlay pieces need careful handling to preserve the thicker silver coating. Avoid abrasive materials and harsh chemicals when maintaining both types, as these can cause tarnishing or damage the surface finish. Storing silver clad and silver overlay artifacts in anti-tarnish bags or cloth helps prevent oxidation and keeps their shine intact.

Silver Clad vs Silver Overlay Infographic

materialdif.com

materialdif.com