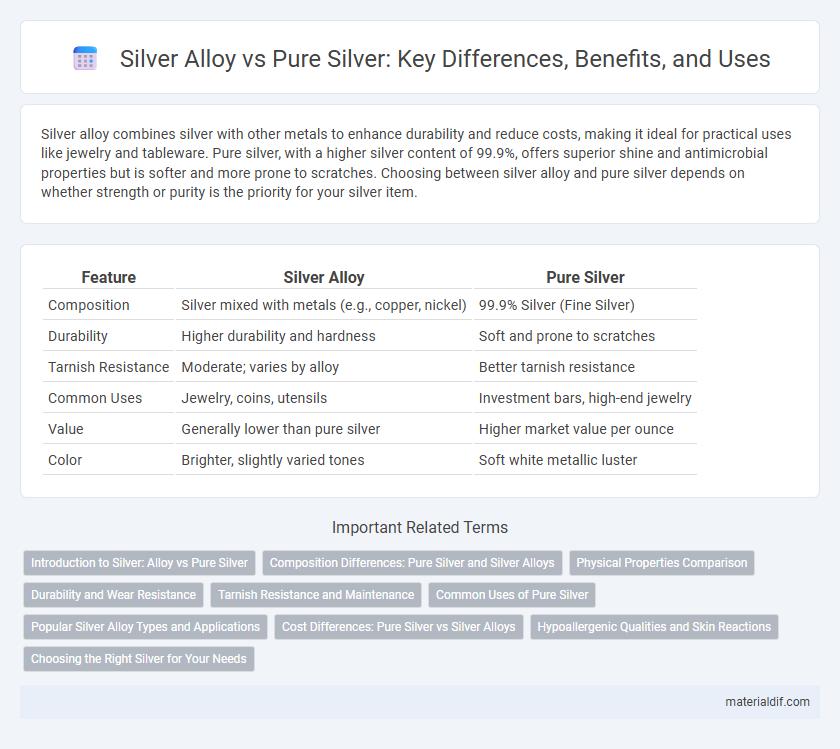

Silver alloy combines silver with other metals to enhance durability and reduce costs, making it ideal for practical uses like jewelry and tableware. Pure silver, with a higher silver content of 99.9%, offers superior shine and antimicrobial properties but is softer and more prone to scratches. Choosing between silver alloy and pure silver depends on whether strength or purity is the priority for your silver item.

Table of Comparison

| Feature | Silver Alloy | Pure Silver |

|---|---|---|

| Composition | Silver mixed with metals (e.g., copper, nickel) | 99.9% Silver (Fine Silver) |

| Durability | Higher durability and hardness | Soft and prone to scratches |

| Tarnish Resistance | Moderate; varies by alloy | Better tarnish resistance |

| Common Uses | Jewelry, coins, utensils | Investment bars, high-end jewelry |

| Value | Generally lower than pure silver | Higher market value per ounce |

| Color | Brighter, slightly varied tones | Soft white metallic luster |

Introduction to Silver: Alloy vs Pure Silver

Silver alloy combines pure silver with other metals such as copper to enhance durability and strength, making it ideal for jewelry, tableware, and coins. Pure silver, typically 99.9% silver, offers superior luster and tarnish resistance but is softer and more prone to damage. Understanding the balance between alloy composition and silver purity is essential for selecting the right silver type based on durability and aesthetic requirements.

Composition Differences: Pure Silver and Silver Alloys

Pure silver consists of 99.9% silver, offering exceptional purity but limited durability. Silver alloys combine silver with metals like copper or nickel, typically comprising 92.5% silver (sterling silver) to enhance strength and resistance to tarnish. These composition differences significantly impact the metal's hardness, malleability, and suitability for various applications such as jewelry and industrial use.

Physical Properties Comparison

Silver alloy contains a mixture of silver and other metals, resulting in enhanced hardness and durability compared to pure silver, which is softer and more malleable. Pure silver exhibits superior conductivity and a brighter, shinier appearance but is prone to scratching and bending under stress. Silver alloys, such as sterling silver with 92.5% silver content, balance physical strength with aesthetic qualities, making them ideal for jewelry and functional items.

Durability and Wear Resistance

Silver alloy, typically composed of 92.5% silver and 7.5% copper, offers significantly enhanced durability and wear resistance compared to pure silver, which is too soft for daily use. The added metals in silver alloy increase hardness, reducing scratches and deformation, making it ideal for jewelry and functional items. Pure silver, while prized for its lustrous appearance and high purity, tends to tarnish and wear down quickly under regular handling and exposure.

Tarnish Resistance and Maintenance

Silver alloys, such as sterling silver, contain copper or other metals that enhance durability but increase susceptibility to tarnish compared to pure silver. Pure silver (99.9% silver) resists tarnishing better due to its higher purity and lack of reactive metals, requiring less frequent polishing. Maintenance of silver alloys involves regular cleaning with anti-tarnish solutions and proper storage to prevent oxidation and prolong shine.

Common Uses of Pure Silver

Pure silver is widely used in high-quality jewelry, silverware, and electronic components due to its excellent conductivity and antimicrobial properties. Its high malleability makes it ideal for intricate designs and fine craftsmanship in decorative arts. Additionally, pure silver is favored in medical applications where sterilization and non-reactivity are critical.

Popular Silver Alloy Types and Applications

Popular silver alloy types include sterling silver, which contains 92.5% pure silver and 7.5% copper, and coin silver, typically consisting of 90% silver with other metals. These alloys enhance durability and resistance to tarnish, making them ideal for jewelry, tableware, and collectible coins. Applications such as electronic connectors and industrial components often use silver alloys due to their improved mechanical properties compared to pure silver.

Cost Differences: Pure Silver vs Silver Alloys

Pure silver, with a 99.9% purity level, typically commands a higher price due to its rarity and superior quality, making it more expensive than silver alloys. Silver alloys, such as sterling silver (92.5% silver mixed with copper or other metals), offer enhanced durability and affordability, reducing their overall cost compared to pure silver. The cost difference is driven by the metal content, with pure silver's higher silver percentage resulting in increased market value and material cost.

Hypoallergenic Qualities and Skin Reactions

Silver alloys, often mixed with metals like copper or nickel, may cause skin reactions in individuals with sensitive or allergy-prone skin due to potential irritants. Pure silver, typically 99.9% silver, is renowned for its hypoallergenic properties and is less likely to trigger allergic responses or dermatitis. Choosing pure silver jewelry or items can minimize skin irritation and offer a safer option for people with metal sensitivities.

Choosing the Right Silver for Your Needs

Silver alloy, typically composed of 92.5% silver and 7.5% other metals such as copper, offers enhanced durability and resistance to tarnish compared to pure silver, which is 99.9% silver but softer and more prone to damage. Choosing silver alloy is ideal for jewelry and everyday items requiring strength and longevity, while pure silver suits applications valuing maximum purity and conductivity, like electronics or high-end silverware. Understanding the specific use and desired properties helps determine whether the hardness of silver alloy or the purity of pure silver best meets your needs.

Silver Alloy vs Pure Silver Infographic

materialdif.com

materialdif.com