Electroplated silver features a thin layer of pure silver deposited onto a base metal, offering enhanced corrosion resistance and aesthetic appeal but with limited durability under heavy use. Roll bonded silver involves mechanically bonding a thick layer of silver to a base metal, providing superior strength and conductivity ideal for industrial applications. Choosing between these depends on the requirement for surface appearance versus structural integrity in silver products.

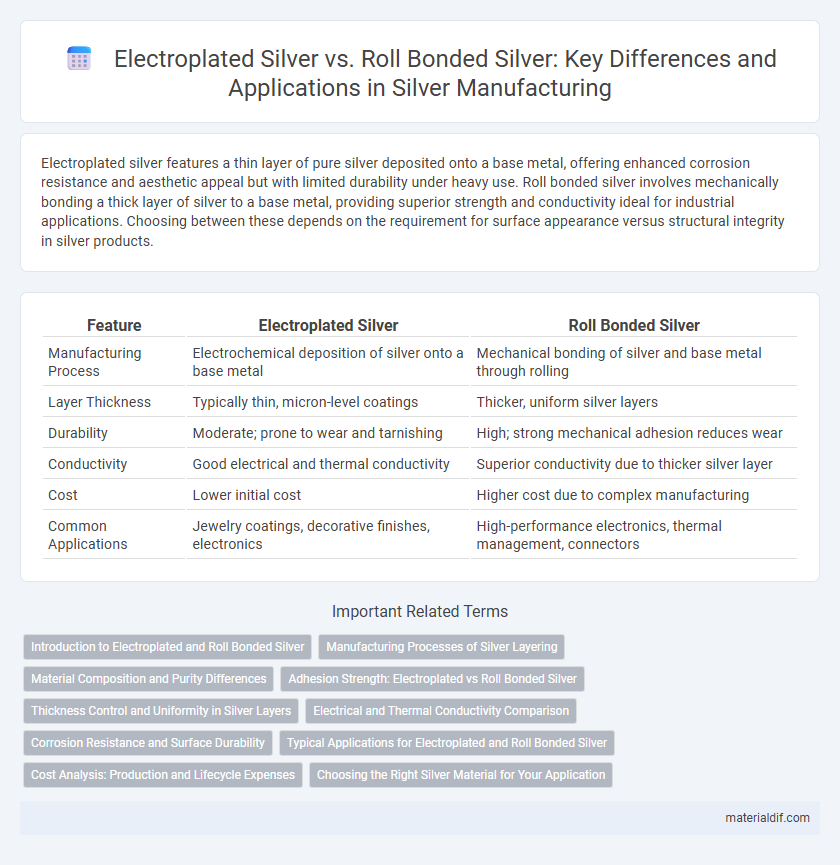

Table of Comparison

| Feature | Electroplated Silver | Roll Bonded Silver |

|---|---|---|

| Manufacturing Process | Electrochemical deposition of silver onto a base metal | Mechanical bonding of silver and base metal through rolling |

| Layer Thickness | Typically thin, micron-level coatings | Thicker, uniform silver layers |

| Durability | Moderate; prone to wear and tarnishing | High; strong mechanical adhesion reduces wear |

| Conductivity | Good electrical and thermal conductivity | Superior conductivity due to thicker silver layer |

| Cost | Lower initial cost | Higher cost due to complex manufacturing |

| Common Applications | Jewelry coatings, decorative finishes, electronics | High-performance electronics, thermal management, connectors |

Introduction to Electroplated and Roll Bonded Silver

Electroplated silver is created by depositing a thin layer of pure silver onto a base metal through an electrochemical process, enhancing appearance and corrosion resistance while reducing costs. Roll bonded silver is manufactured by pressing thin layers of silver and copper together under high pressure and heat, resulting in a durable, solid metal with excellent conductivity and strength. Both techniques are widely used in jewelry, electronics, and industrial applications, offering different balances between material efficiency and performance.

Manufacturing Processes of Silver Layering

Electroplated silver involves depositing a thin silver layer onto a substrate through an electrolytic process, ensuring uniform coating but typically resulting in a thinner layer with lower mechanical strength. Roll bonded silver is produced by pressing and rolling silver sheets onto a base metal, creating a metallurgical bond that provides a thicker, more durable layer with enhanced thermal and electrical conductivity. Manufacturing electroplated silver is cost-effective for intricate designs, while roll bonding is preferred for applications requiring robust silver layers and improved performance.

Material Composition and Purity Differences

Electroplated silver features a thin layer of pure silver deposited onto a base metal substrate, often copper or nickel, resulting in a surface with high luster but variable overall purity. Roll bonded silver consists of multiple layers of pure silver and other metals mechanically bonded through pressure and heat, ensuring a consistent and higher purity level throughout the material. The material composition in roll bonded silver provides enhanced durability and conductivity compared to the thinner, less uniform silver layer in electroplated products.

Adhesion Strength: Electroplated vs Roll Bonded Silver

Electroplated silver typically exhibits lower adhesion strength due to the thin, deposited layer, making it more prone to peeling under stress. Roll bonded silver forms a metallurgical bond through pressure and heat, resulting in superior adhesion strength ideal for demanding applications. This difference in bonding methods directly affects the durability and reliability of silver coatings in industrial uses.

Thickness Control and Uniformity in Silver Layers

Electroplated silver offers precise thickness control through adjustable deposition rates, enabling uniform silver layers crucial for consistent conductivity and corrosion resistance. Roll bonded silver achieves thickness uniformity by mechanically bonding silver sheets, providing stable layer thickness but with less fine control compared to electroplating. Thickness uniformity in electroplated silver typically results in smoother surfaces, while roll bonded silver layers can exhibit slight variability due to mechanical rolling processes.

Electrical and Thermal Conductivity Comparison

Electroplated silver features a thin layer of silver coating applied to a base metal, resulting in moderate electrical and thermal conductivity limited by the substrate material. Roll bonded silver consists of multiple silver layers laminated together under high pressure, offering superior electrical and thermal conductivity due to the continuous pure silver matrix. Roll bonded silver excels in applications requiring efficient heat dissipation and low electrical resistance compared to electroplated silver.

Corrosion Resistance and Surface Durability

Electroplated silver offers a thin, uniform coating that enhances surface durability but may be prone to corrosion if the underlying metal is exposed or damaged. Roll bonded silver, featuring a thicker interlayer of pure silver laminated to a base metal, provides superior corrosion resistance and long-lasting surface integrity. This method ensures enhanced protection against tarnishing and wear, making roll bonded silver ideal for applications requiring durability and sustained aesthetic appeal.

Typical Applications for Electroplated and Roll Bonded Silver

Electroplated silver is commonly used in jewelry, decorative items, and electronic components where a thin, uniform coating with excellent conductivity and corrosion resistance is essential. Roll bonded silver is preferred for industrial and electrical applications such as battery connectors, bus bars, and thermal management systems due to its superior mechanical strength and high conductivity. Both materials leverage silver's excellent electrical and thermal properties but target different performance requirements in their typical applications.

Cost Analysis: Production and Lifecycle Expenses

Electroplated silver involves applying a thin layer of silver on a base metal, resulting in lower initial production costs but potentially higher lifecycle expenses due to wear and re-plating requirements. Roll bonded silver combines layers of silver and other metals through heat and pressure, leading to higher upfront manufacturing costs but enhanced durability and extended lifespan, reducing long-term maintenance expenses. Cost analysis reveals that electroplated silver suits applications with short-term use, while roll bonded silver offers better value in high-stress or long-term environments.

Choosing the Right Silver Material for Your Application

Electroplated silver offers a thin, uniform coating ideal for decorative and corrosion-resistant applications, ensuring a cost-effective solution when high conductivity is not critical. Roll bonded silver features a solid, layered construction providing superior electrical conductivity and mechanical strength, making it suitable for high-performance electrical and thermal applications. Selecting between electroplated and roll bonded silver depends on the required durability, conductivity, and budget considerations specific to your project's demands.

Electroplated Silver vs Roll Bonded Silver Infographic

materialdif.com

materialdif.com