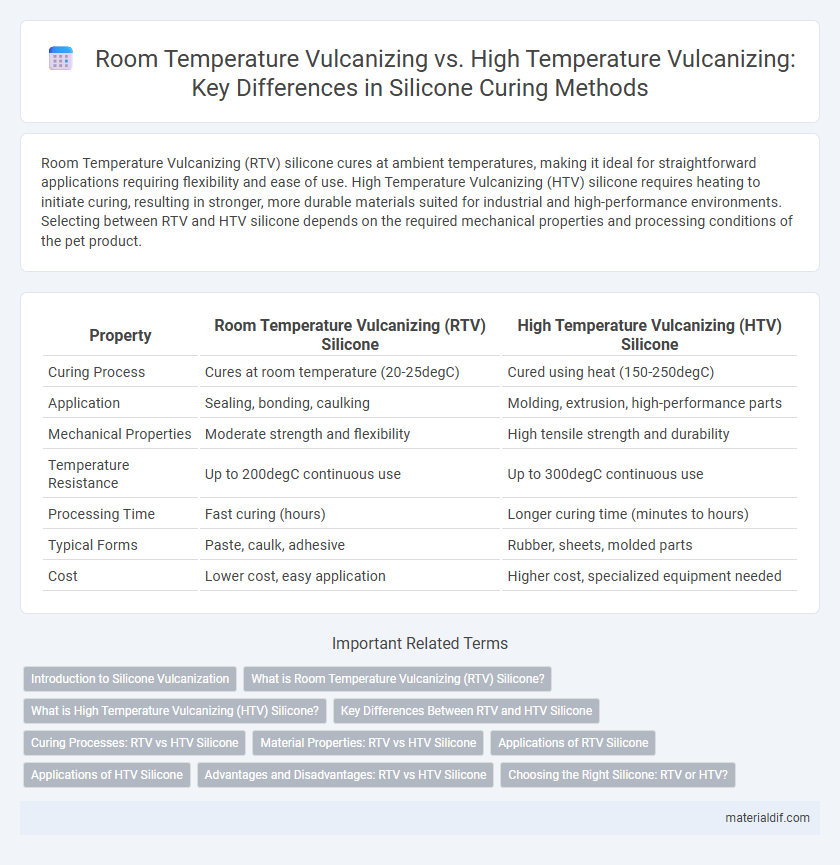

Room Temperature Vulcanizing (RTV) silicone cures at ambient temperatures, making it ideal for straightforward applications requiring flexibility and ease of use. High Temperature Vulcanizing (HTV) silicone requires heating to initiate curing, resulting in stronger, more durable materials suited for industrial and high-performance environments. Selecting between RTV and HTV silicone depends on the required mechanical properties and processing conditions of the pet product.

Table of Comparison

| Property | Room Temperature Vulcanizing (RTV) Silicone | High Temperature Vulcanizing (HTV) Silicone |

|---|---|---|

| Curing Process | Cures at room temperature (20-25degC) | Cured using heat (150-250degC) |

| Application | Sealing, bonding, caulking | Molding, extrusion, high-performance parts |

| Mechanical Properties | Moderate strength and flexibility | High tensile strength and durability |

| Temperature Resistance | Up to 200degC continuous use | Up to 300degC continuous use |

| Processing Time | Fast curing (hours) | Longer curing time (minutes to hours) |

| Typical Forms | Paste, caulk, adhesive | Rubber, sheets, molded parts |

| Cost | Lower cost, easy application | Higher cost, specialized equipment needed |

Introduction to Silicone Vulcanization

Silicone vulcanization is the chemical process that transforms silicone polymers into durable elastomers through cross-linking. Room Temperature Vulcanizing (RTV) silicones cure at ambient temperatures, making them ideal for sealants and adhesives with excellent flexibility and weather resistance. High Temperature Vulcanizing (HTV) silicones require elevated temperatures during curing, producing heat-resistant, mechanically robust materials used in automotive and industrial applications.

What is Room Temperature Vulcanizing (RTV) Silicone?

Room Temperature Vulcanizing (RTV) silicone is a type of silicone rubber that cures at ambient temperatures without the need for additional heat sources. It typically consists of a base polymer and a curing agent that react upon exposure to moisture in the air, forming a flexible, durable, and chemically resistant elastomer. RTV silicone is widely used for sealing, bonding, and molding applications due to its ease of application and excellent adhesion to various substrates.

What is High Temperature Vulcanizing (HTV) Silicone?

High Temperature Vulcanizing (HTV) silicone is a type of silicone rubber that cures at elevated temperatures, typically between 150degC and 250degC, resulting in a durable, heat-resistant elastomer. HTV silicones exhibit excellent mechanical properties, chemical resistance, and thermal stability, making them suitable for demanding applications in automotive, aerospace, and industrial sectors. Unlike Room Temperature Vulcanizing (RTV) silicones, HTV silicones require high-temperature ovens or presses for curing, which produces a tougher, more resilient material ideal for high-performance environments.

Key Differences Between RTV and HTV Silicone

RTV silicone cures at room temperature through moisture exposure, making it ideal for easy application and flexible sealing in low-heat environments. HTV silicone requires high-temperature curing, typically above 150degC, resulting in superior mechanical strength and thermal resistance suited for industrial and automotive components. The key differences include curing conditions, mechanical properties, and typical applications, with RTV preferred for low-stress seals and HTV favored for durable, heat-resistant parts.

Curing Processes: RTV vs HTV Silicone

RTV silicone cures at room temperature through a moisture-induced cross-linking process, making it ideal for applications requiring ease of use and fast curing without specialized equipment. HTV silicone undergoes a high-temperature curing process, typically between 150degC and 250degC, resulting in superior mechanical strength and thermal stability for demanding industrial applications. The choice between RTV and HTV silicone depends on factors such as processing conditions, desired material properties, and end-use performance requirements.

Material Properties: RTV vs HTV Silicone

RTV (Room Temperature Vulcanizing) silicone cures at ambient temperatures, offering flexibility, excellent electrical insulation, and resistance to moisture, making it ideal for sealing and bonding applications. HTV (High Temperature Vulcanizing) silicone requires heat to cure, resulting in superior mechanical strength, thermal stability up to 300degC, and enhanced chemical resistance suitable for high-performance industrial uses. The key material property difference lies in RTV's ease of use and elasticity versus HTV's durability and high-temperature endurance.

Applications of RTV Silicone

RTV silicone is widely used in sealing, coating, and molding applications due to its ability to cure at room temperature, making it ideal for onsite repairs and intricate molds. It provides excellent adhesion, flexibility, and resistance to moisture and chemicals, which is crucial for automotive gaskets, electrical insulation, and household appliance seals. Unlike HTV silicone that requires high-temperature curing, RTV silicone enables faster turnaround times and ease of use for both industrial and consumer products.

Applications of HTV Silicone

High Temperature Vulcanizing (HTV) silicone is widely used in applications requiring exceptional thermal stability, such as automotive engines, aerospace components, and industrial machinery seals. Its ability to withstand temperatures up to 300degC makes HTV silicone ideal for gaskets, O-rings, and vibration damping materials exposed to extreme heat. Unlike Room Temperature Vulcanizing (RTV) silicone, HTV silicone exhibits superior mechanical strength and chemical resistance, enhancing durability in demanding environments.

Advantages and Disadvantages: RTV vs HTV Silicone

RTV silicone cures at room temperature, offering ease of use and fast curing without special equipment, making it ideal for prototypes and small-scale applications; however, it generally has lower heat resistance and mechanical strength compared to HTV silicone. HTV silicone requires high temperature curing, resulting in superior durability, high thermal stability up to 250degC, and enhanced mechanical properties suited for industrial and automotive uses, but demands specialized curing ovens and longer processing times. Choosing between RTV and HTV silicone depends on application requirements such as temperature exposure, production scale, and mechanical stress tolerance.

Choosing the Right Silicone: RTV or HTV?

Room Temperature Vulcanizing (RTV) silicone cures at ambient temperatures, offering ease of application and flexibility, making it ideal for general sealing and molding tasks. High Temperature Vulcanizing (HTV) silicone requires elevated heat for curing, resulting in superior mechanical strength and thermal stability suited for demanding industrial environments. Selecting between RTV and HTV silicones depends on the specific application conditions, such as temperature resistance, durability requirements, and curing process constraints.

Room Temperature Vulcanizing vs High Temperature Vulcanizing Infographic

materialdif.com

materialdif.com