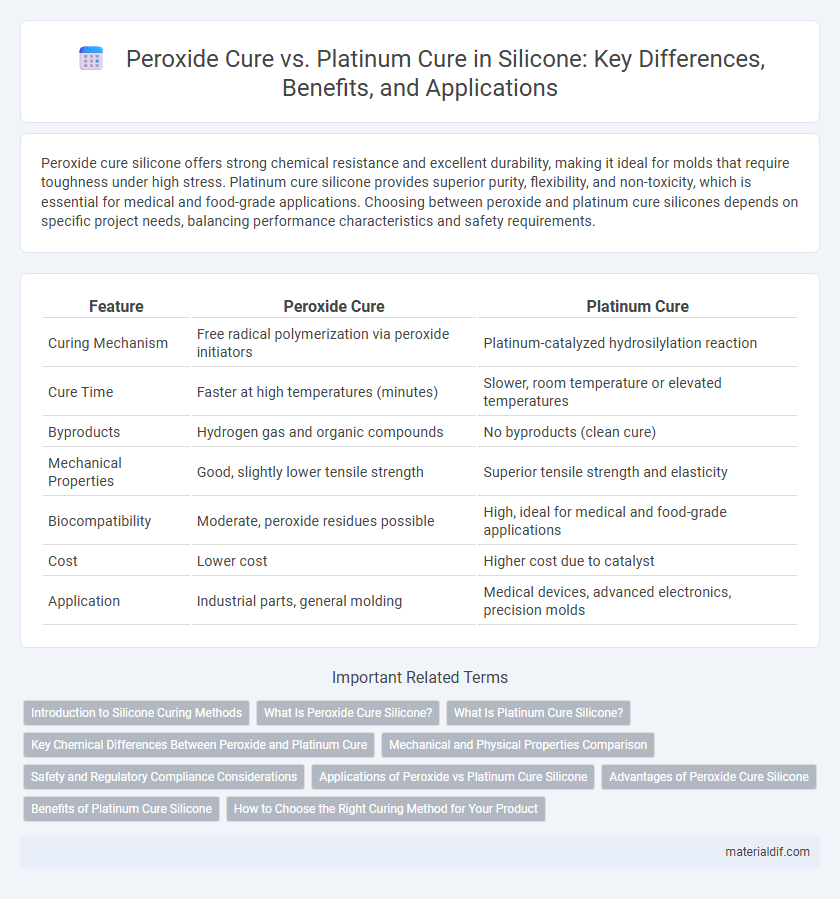

Peroxide cure silicone offers strong chemical resistance and excellent durability, making it ideal for molds that require toughness under high stress. Platinum cure silicone provides superior purity, flexibility, and non-toxicity, which is essential for medical and food-grade applications. Choosing between peroxide and platinum cure silicones depends on specific project needs, balancing performance characteristics and safety requirements.

Table of Comparison

| Feature | Peroxide Cure | Platinum Cure |

|---|---|---|

| Curing Mechanism | Free radical polymerization via peroxide initiators | Platinum-catalyzed hydrosilylation reaction |

| Cure Time | Faster at high temperatures (minutes) | Slower, room temperature or elevated temperatures |

| Byproducts | Hydrogen gas and organic compounds | No byproducts (clean cure) |

| Mechanical Properties | Good, slightly lower tensile strength | Superior tensile strength and elasticity |

| Biocompatibility | Moderate, peroxide residues possible | High, ideal for medical and food-grade applications |

| Cost | Lower cost | Higher cost due to catalyst |

| Application | Industrial parts, general molding | Medical devices, advanced electronics, precision molds |

Introduction to Silicone Curing Methods

Peroxide cure and platinum cure are two primary silicone curing methods essential for transforming liquid silicone into solid elastomers. Peroxide cure relies on free radicals generated by organic peroxides to initiate cross-linking, suitable for applications requiring high heat resistance. Platinum cure uses a platinum-based catalyst enabling an addition reaction that provides superior clarity, biocompatibility, and odorless properties, making it ideal for medical and food-grade silicone products.

What Is Peroxide Cure Silicone?

Peroxide cure silicone is a type of silicone rubber that uses organic peroxides as curing agents to initiate cross-linking during vulcanization, resulting in a strong, heat-resistant elastomer. This curing method allows for greater flexibility in formulation and cost-effectiveness, making it suitable for applications like mold-making, gaskets, and automotive parts. Compared to platinum cure silicone, peroxide cure silicone may leave slight residues and have lower transparency but offers excellent thermal stability and chemical resistance.

What Is Platinum Cure Silicone?

Platinum cure silicone, also known as addition-cure silicone, utilizes a platinum catalyst to initiate cross-linking during the curing process, resulting in a more precise and stable silicone rubber. This method produces materials with superior tear resistance, low shrinkage, and excellent biocompatibility, making it ideal for medical devices, food contact products, and high-precision molds. Unlike peroxide cure silicones, platinum cure silicones do not release by-products during curing, ensuring a cleaner, odorless, and more environmentally friendly process.

Key Chemical Differences Between Peroxide and Platinum Cure

Peroxide-cure silicones use organic peroxides to initiate cross-linking through free radical mechanisms, resulting in the release of byproducts such as alcohol or ketones during the curing process. In contrast, platinum-cure silicones employ a hydrosilylation reaction catalyzed by platinum complexes, which creates cross-links without generating volatile byproducts, leading to purer and more stable elastomers. The chemical distinction lies in the peroxide's radical-induced curing versus the platinum catalyst's addition-cure mechanism, impacting the final material properties and application suitability.

Mechanical and Physical Properties Comparison

Peroxide cure silicones typically exhibit superior tear strength and higher resistance to compression set compared to platinum cure silicones, making them ideal for applications demanding durability under mechanical stress. Platinum cure silicones offer enhanced purity, resulting in better chemical stability and elasticity, with low shrinkage and superior thermal resistance that suits high-precision molding. Both curing methods affect tensile strength and elongation differently, where peroxide cure silicones generally present higher tensile strength, while platinum cure silicone maintains greater elongation at break.

Safety and Regulatory Compliance Considerations

Peroxide cure silicones contain organic peroxides that release by-products like hydrogen gas and acetone during curing, requiring careful ventilation and handling to meet safety standards. Platinum cure silicones, often preferred in medical and food-grade applications, are free from hazardous by-products and comply with stringent regulatory frameworks such as FDA and ISO 10993 biocompatibility standards. Choosing platinum cure silicone enhances regulatory compliance and minimizes health risks associated with residual cure agents or volatile emissions.

Applications of Peroxide vs Platinum Cure Silicone

Peroxide cure silicone is widely used in applications requiring high heat resistance and strong chemical bonding, such as automotive gaskets, electrical insulation, and cookware molds. Platinum cure silicone excels in medical, food-grade, and baby product applications due to its superior biocompatibility and low toxicity. Industries prefer peroxide cure for robust, industrial-grade projects, while platinum cure is favored for precision molding and sensitive material contact.

Advantages of Peroxide Cure Silicone

Peroxide cure silicone offers advantages such as excellent chemical resistance and the ability to cure in thicker sections without inhibition from contaminants. It provides better mechanical properties like higher tear strength and flexibility, making it suitable for durable and high-performance applications. Additionally, peroxide cure silicone typically has a longer shelf life and is more cost-effective compared to platinum cure silicone.

Benefits of Platinum Cure Silicone

Platinum cure silicone offers superior biocompatibility and hypoallergenic properties, making it ideal for medical and food-grade applications. Its high tear strength and excellent resistance to heat and chemicals ensure durable and long-lasting performance. Unlike peroxide cure silicones, platinum cure formulations produce no by-products during curing, resulting in cleaner, odorless, and more stable end products.

How to Choose the Right Curing Method for Your Product

Selecting the appropriate silicone curing method depends on the product's application, cost constraints, and performance requirements. Peroxide cure silicones offer strong heat resistance and faster curing times, ideal for high-temperature environments, while platinum cure silicones provide superior biocompatibility, clarity, and low shrinkage, making them suitable for medical and food-grade products. Evaluating factors such as desired mechanical properties, regulatory compliance, and production volume ensures the optimal choice between peroxide and platinum cure systems.

Peroxide Cure vs Platinum Cure Infographic

materialdif.com

materialdif.com