Raw linen consists of unprocessed flax fibers that retain their natural texture, color, and stiffness, making it less smooth but highly durable. Finished linen undergoes processes like bleaching, dyeing, and softening, resulting in a softer, more polished fabric that is ideal for clothing and home textiles. The transformation from raw to finished linen enhances comfort and aesthetic appeal while preserving the material's breathability and strength.

Table of Comparison

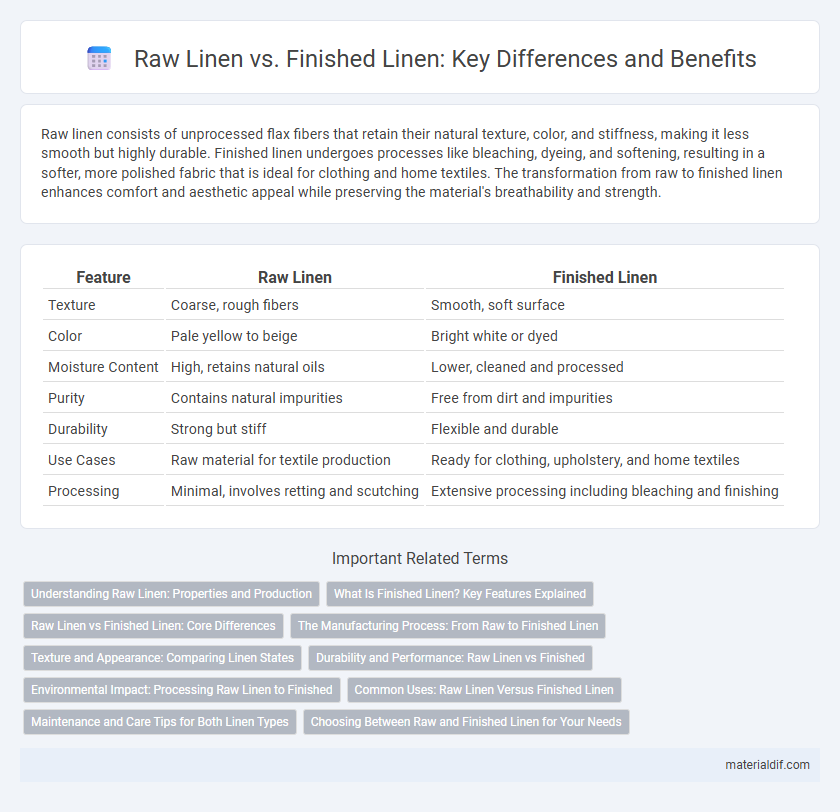

| Feature | Raw Linen | Finished Linen |

|---|---|---|

| Texture | Coarse, rough fibers | Smooth, soft surface |

| Color | Pale yellow to beige | Bright white or dyed |

| Moisture Content | High, retains natural oils | Lower, cleaned and processed |

| Purity | Contains natural impurities | Free from dirt and impurities |

| Durability | Strong but stiff | Flexible and durable |

| Use Cases | Raw material for textile production | Ready for clothing, upholstery, and home textiles |

| Processing | Minimal, involves retting and scutching | Extensive processing including bleaching and finishing |

Understanding Raw Linen: Properties and Production

Raw linen retains natural fibers from flax plants, characterized by coarse texture, high strength, and moisture-wicking properties essential for durability and breathability. The production of raw linen involves retting, scutching, and hackling to separate fibers, ensuring sustainable extraction without compromising fiber quality. Understanding raw linen's natural properties provides insight into the transformative finishing processes that enhance softness, color, and fabric flexibility in finished linen products.

What Is Finished Linen? Key Features Explained

Finished linen refers to linen fabric that has undergone processes like bleaching, dyeing, and calendaring to enhance its texture, color, and durability. Key features of finished linen include a smooth surface, improved softness, and increased resistance to wrinkles and shrinkage compared to raw linen. This treatment transforms raw linen fibers, which are coarse and stiff, into a more refined and usable textile for apparel and home furnishings.

Raw Linen vs Finished Linen: Core Differences

Raw linen consists of unprocessed flax fibers harvested from the flax plant, retaining natural impurities and a coarse texture, while finished linen undergoes cleaning, spinning, weaving, and sometimes bleaching or dyeing to create soft, durable fabric. The primary differences lie in texture, appearance, and usability, with raw linen being rough and stiff, and finished linen smooth and suitable for textiles or clothing. Finished linen also exhibits enhanced strength, uniform color, and improved moisture-wicking properties compared to raw linen.

The Manufacturing Process: From Raw to Finished Linen

The manufacturing process of linen begins with raw flax fibers harvested from the flax plant, which undergo retting, drying, and scutching to separate the fiber from the stalk. These raw fibers are then combed and spun into yarn, followed by weaving or knitting into fabric before dyeing and finishing treatments enhance texture, durability, and appearance. Finished linen displays superior softness, strength, and breathability compared to raw linen, making it ideal for high-quality textiles.

Texture and Appearance: Comparing Linen States

Raw linen exhibits a coarse, stiff texture with visible fibers and a natural, slightly uneven appearance, highlighting its unprocessed state. Finished linen features a smoother, softer texture achieved through washing and ironing, resulting in a refined, uniform surface ideal for textiles. The transformation from raw to finished linen significantly enhances visual appeal and tactile comfort, making finished linen more desirable for clothing and home decor.

Durability and Performance: Raw Linen vs Finished

Raw linen exhibits higher tensile strength due to its unprocessed fibers, offering superior durability for heavy-duty applications. Finished linen, enhanced by treatments and refinements, delivers improved softness, flexibility, and resistance to wear, making it ideal for everyday use and comfort. Performance differences highlight raw linen's robustness against physical strain, while finished linen provides a balanced combination of endurance and user-friendly texture.

Environmental Impact: Processing Raw Linen to Finished

Processing raw linen into finished linen significantly reduces environmental impact by utilizing eco-friendly practices like water-efficient retting and natural fiber extraction, which minimize chemical use and waste. Finished linen production often incorporates sustainable methods such as enzymatic treatments and water recycling systems, lowering energy consumption and pollution compared to synthetic fibers. The biodegradability and durability of finished linen contribute to a reduced carbon footprint throughout its lifecycle, promoting a circular economy in textile manufacturing.

Common Uses: Raw Linen Versus Finished Linen

Raw linen, known for its coarse texture and natural impurities, is commonly used in industrial applications such as upholstery backing, canvas production, and packaging materials where durability is essential. Finished linen undergoes processes like bleaching, dyeing, and softening, making it ideal for high-quality textiles, including bedding, apparel, and home decor fabrics that require a smooth, refined appearance. The transformation from raw to finished linen enhances its versatility, catering to both heavy-duty uses and delicate, fashion-forward products.

Maintenance and Care Tips for Both Linen Types

Raw linen requires gentle washing in cold water with mild detergent to prevent fiber damage, while finished linen can tolerate slightly warmer temperatures and delicate machine washing. Both linen types benefit from air drying and ironing while damp to maintain fabric integrity and prevent excessive wrinkling. Storing linen in a cool, dry place away from direct sunlight preserves color and texture for long-lasting use.

Choosing Between Raw and Finished Linen for Your Needs

Raw linen offers a coarser texture and greater absorbency, ideal for heavy-duty or craft applications, while finished linen provides a smoother feel and enhanced durability suited for garments and home textiles. Selecting between raw and finished linen depends on the intended use, with raw linen favored for eco-friendly projects and finished linen preferred for comfort and aesthetic appeal. Consider factors like texture, strength, and maintenance requirements to ensure the linen matches your specific needs.

Raw Linen vs Finished Linen Infographic

materialdif.com

materialdif.com