Linen weave features a distinct texture created by interlacing thicker yarns in a pattern that highlights the natural irregularities of flax fibers, offering enhanced durability and breathability compared to plain weave. Plain weave, characterized by its simple over-and-under pattern, produces a smooth and uniform surface but lacks the unique tactile quality and resilience found in linen weave. The choice between linen weave and plain weave impacts fabric strength, appearance, and comfort, with linen weave excelling in strength and texture.

Table of Comparison

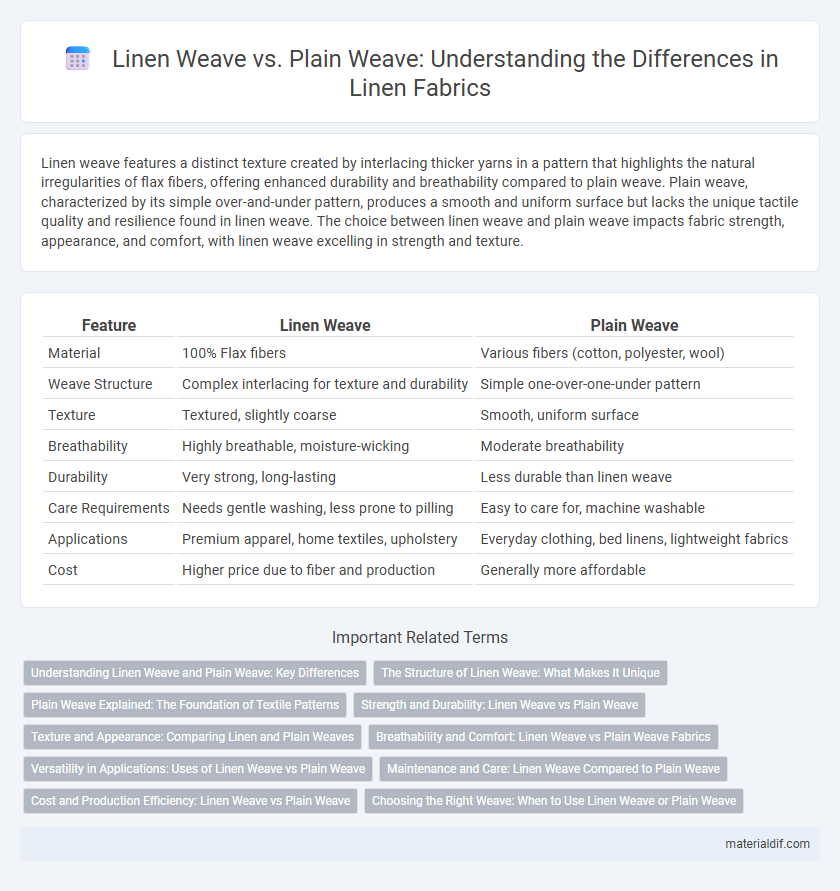

| Feature | Linen Weave | Plain Weave |

|---|---|---|

| Material | 100% Flax fibers | Various fibers (cotton, polyester, wool) |

| Weave Structure | Complex interlacing for texture and durability | Simple one-over-one-under pattern |

| Texture | Textured, slightly coarse | Smooth, uniform surface |

| Breathability | Highly breathable, moisture-wicking | Moderate breathability |

| Durability | Very strong, long-lasting | Less durable than linen weave |

| Care Requirements | Needs gentle washing, less prone to pilling | Easy to care for, machine washable |

| Applications | Premium apparel, home textiles, upholstery | Everyday clothing, bed linens, lightweight fabrics |

| Cost | Higher price due to fiber and production | Generally more affordable |

Understanding Linen Weave and Plain Weave: Key Differences

Linen weave typically refers to the use of flax fibers woven with a plain weave, creating a strong and breathable fabric prized for durability and texture. The plain weave is the simplest and most common weaving pattern featuring a one-over-one-under interlacing, providing uniform strength and a smooth surface ideal for fine linens. Key differences lie in the fiber origin--linen from flax--and the weave structure, where plain weave defines the technique used, applicable to various fibers beyond linen.

The Structure of Linen Weave: What Makes It Unique

Linen weave is characterized by its distinctive interlacing pattern, where warp and weft threads cross in a balanced, tight formation, creating a durable and breathable fabric. Unlike plain weave, linen weave incorporates a textured surface made from flax fibers, which enhances moisture absorption and gives it a naturally crisp feel. This unique structure allows linen to maintain strength while providing superior air circulation, making it ideal for lightweight, comfortable textiles.

Plain Weave Explained: The Foundation of Textile Patterns

Plain weave, the simplest and most common textile pattern, forms the foundation of many linen fabrics through an alternating over-under thread sequence, creating a durable and balanced structure. This weave enhances linen's natural strength and breathability, making it ideal for clothing and home textiles. Compared to more complex patterns like linen weave, plain weave offers uniform texture and greater resistance to wear and tear.

Strength and Durability: Linen Weave vs Plain Weave

Linen weave, derived from flax fibers, exhibits superior strength and durability compared to plain weave due to its unique interlacing pattern that enhances fabric resilience and longevity. The tighter weave structure of linen weave reduces fiber abrasion and wear over time, making it ideal for heavy-use applications such as upholstery and high-quality garments. In contrast, plain weave, characterized by its simple over-under pattern, offers moderate durability but is more prone to fraying and less resistant to tension than linen weave.

Texture and Appearance: Comparing Linen and Plain Weaves

Linen weave features a slightly rougher texture with visible irregularities that enhance its natural, rustic appearance, while plain weave offers a smoother, more uniform surface ideal for crisp, clean finishes. The open construction of linen weave allows for better breathability and a looser drape compared to the tighter, firmer structure of plain weave. Linen fabrics often showcase a distinctive slub texture that adds depth and character, contrasting with the consistent, flat look typical of plain weave textiles.

Breathability and Comfort: Linen Weave vs Plain Weave Fabrics

Linen weave fabrics offer superior breathability due to their characteristic loose and open structure, allowing better air circulation compared to plain weave fabrics. This enhanced airflow helps regulate body temperature, making linen weave ideal for warm weather clothing and home textiles. Plain weave fabrics, while durable and tightly woven, tend to trap heat and moisture, resulting in less comfort during hot and humid conditions.

Versatility in Applications: Uses of Linen Weave vs Plain Weave

Linen weave, characterized by its looser and more textured pattern, offers superior breathability and is ideal for home textiles such as curtains, upholstery, and table linens where durability and aesthetic appeal are essential. Plain weave, with its tighter structure and greater strength, is widely used in apparel, bags, and industrial fabrics requiring firm construction and wear resistance. The versatility of linen weave suits decorative and functional applications demanding airflow and softness, while plain weave excels in products needing robust and long-lasting fabric performance.

Maintenance and Care: Linen Weave Compared to Plain Weave

Linen weave, characterized by its distinct texture and durability, requires specific maintenance to preserve its breathability and strength, often benefiting from gentle washing and air drying to prevent fiber weakening. Plain weave, while simpler and generally more resilient to frequent laundering, may not offer the same level of moisture-wicking and tends to show wear faster under heavy use. Proper care for linen weave includes avoiding harsh detergents and high heat, promoting longevity compared to the more straightforward care routine typical for plain weave fabrics.

Cost and Production Efficiency: Linen Weave vs Plain Weave

Linen weave, characterized by its durable and textured structure, generally incurs higher production costs due to the complexity of weaving thicker flax fibers compared to the simpler and faster process of plain weave. Plain weave offers superior production efficiency with lower material waste and faster loom speeds, making it more cost-effective for mass manufacturing. The increased labor and slower production rates associated with linen weave often result in higher market prices despite its premium quality and durability.

Choosing the Right Weave: When to Use Linen Weave or Plain Weave

Linen weave, characterized by its textured surface and durability, is ideal for upholstery and home decor where robustness and breathability are essential. Plain weave offers a smoother, tighter construction suited for lightweight apparel and fine linens, providing comfort and a refined appearance. Selecting between linen weave and plain weave depends on the fabric's intended use, balancing factors like strength, texture, and breathability to meet specific functional and aesthetic needs.

Linen Weave vs Plain Weave Infographic

materialdif.com

materialdif.com