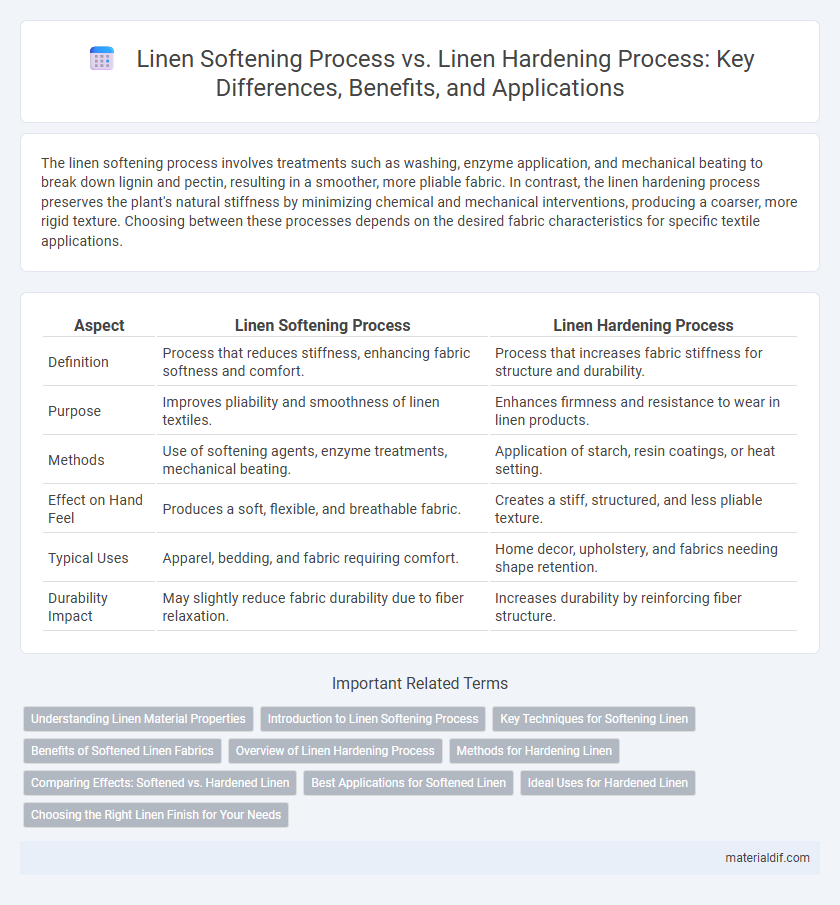

The linen softening process involves treatments such as washing, enzyme application, and mechanical beating to break down lignin and pectin, resulting in a smoother, more pliable fabric. In contrast, the linen hardening process preserves the plant's natural stiffness by minimizing chemical and mechanical interventions, producing a coarser, more rigid texture. Choosing between these processes depends on the desired fabric characteristics for specific textile applications.

Table of Comparison

| Aspect | Linen Softening Process | Linen Hardening Process |

|---|---|---|

| Definition | Process that reduces stiffness, enhancing fabric softness and comfort. | Process that increases fabric stiffness for structure and durability. |

| Purpose | Improves pliability and smoothness of linen textiles. | Enhances firmness and resistance to wear in linen products. |

| Methods | Use of softening agents, enzyme treatments, mechanical beating. | Application of starch, resin coatings, or heat setting. |

| Effect on Hand Feel | Produces a soft, flexible, and breathable fabric. | Creates a stiff, structured, and less pliable texture. |

| Typical Uses | Apparel, bedding, and fabric requiring comfort. | Home decor, upholstery, and fabrics needing shape retention. |

| Durability Impact | May slightly reduce fabric durability due to fiber relaxation. | Increases durability by reinforcing fiber structure. |

Understanding Linen Material Properties

The linen softening process enhances fiber flexibility and increases moisture absorption, making the fabric more comfortable and breathable for wear. Conversely, the linen hardening process increases stiffness and durability by reducing fiber pliability, which is ideal for structural applications requiring toughness. Understanding these contrasting treatments allows precise control over the linen's texture and performance based on its end-use requirements.

Introduction to Linen Softening Process

The linen softening process involves treating flax fibers to enhance their flexibility, smoothness, and overall tactile comfort, making the fabric more suitable for apparel and home textiles. This process typically includes enzymatic treatments, washing, and mechanical agitation, which reduce lignin and pectin content that cause stiffness and coarse texture. Effective softening improves linen's drape and absorbency, contributing to its luxurious feel and versatility in various textile applications.

Key Techniques for Softening Linen

Key techniques for softening linen include enzymatic treatment, which breaks down pectin and lignin fibers to enhance fabric pliability. Mechanical methods such as steam softening and calendaring smooth the fibers and increase fabric flexibility. Chemical softeners, often based on silicone or fatty acids, are applied to reduce stiffness and improve the tactile softness of linen fabrics.

Benefits of Softened Linen Fabrics

Softened linen fabrics offer enhanced comfort and improved breathability, making them ideal for clothing and home textiles that require a gentle touch on the skin. The softening process also increases the fabric's flexibility and drape, resulting in garments that are easier to wear and maintain. These benefits contrast with the linen hardening process, which prioritizes stiffness and durability but may compromise comfort and texture.

Overview of Linen Hardening Process

The linen hardening process involves treating the fibers with chemicals such as starch or resin to increase stiffness and durability, making the fabric more resistant to wrinkles and wear. This process enhances the structural integrity of linen, often used for heavier textiles or upholstery where firmness is desired. Unlike softening, hardening reduces flexibility but improves the fabric's ability to maintain shape and resist shrinkage during laundering.

Methods for Hardening Linen

Methods for hardening linen primarily involve the application of metal salts or starch-based sizing to create stiffness and durability. Alum and tannin treatments chemically bond with linen fibers, producing a firm texture suitable for industrial or decorative uses. Heat-setting techniques further reinforce fiber rigidity by altering the molecular structure without compromising linen's natural breathability.

Comparing Effects: Softened vs. Hardened Linen

Softened linen exhibits enhanced flexibility, improved drape, and increased comfort, making it ideal for clothing and bedding applications. Hardened linen, due to starching or resin treatments, becomes more rigid and durable, suitable for upholstery and protective textiles. The softening process maintains the fabric's breathability, while hardening compromises flexibility but increases resistance to wear and wrinkle retention.

Best Applications for Softened Linen

The linen softening process enhances fabric pliability and comfort by breaking down fibers and removing stiffness, making it ideal for clothing, bedding, and upholstery where softness is crucial. Softened linen exhibits improved drape and breathability, perfect for garments like shirts, dresses, and casual wear that require gentle texture against the skin. In contrast, linen hardening processes prioritize durability and structure, better suited for industrial uses and heavy-duty textiles.

Ideal Uses for Hardened Linen

Hardened linen undergoes a stiffening treatment that enhances durability and structural integrity, making it ideal for applications requiring firm support such as upholstery, bookbinding, and industrial textiles. This process increases resistance to wear and deformation, providing a crisp texture suitable for crafts and home decor items that benefit from a robust, non-flexible fabric. In contrast, softened linen prioritizes comfort and flexibility, better suited for clothing and bedding where a gentler touch is desired.

Choosing the Right Linen Finish for Your Needs

The linen softening process involves treatments like beating, enzyme application, and softening agents to enhance fabric flexibility and comfort, ideal for apparel and bedding. Conversely, the linen hardening process uses starching or resin finishes to add stiffness and durability, suited for upholstery or decorative textiles requiring structural integrity. Selecting the right linen finish depends on the intended use, balancing softness for wearability with hardness for durability and aesthetic preference.

Linen Softening Process vs Linen Hardening Process Infographic

materialdif.com

materialdif.com