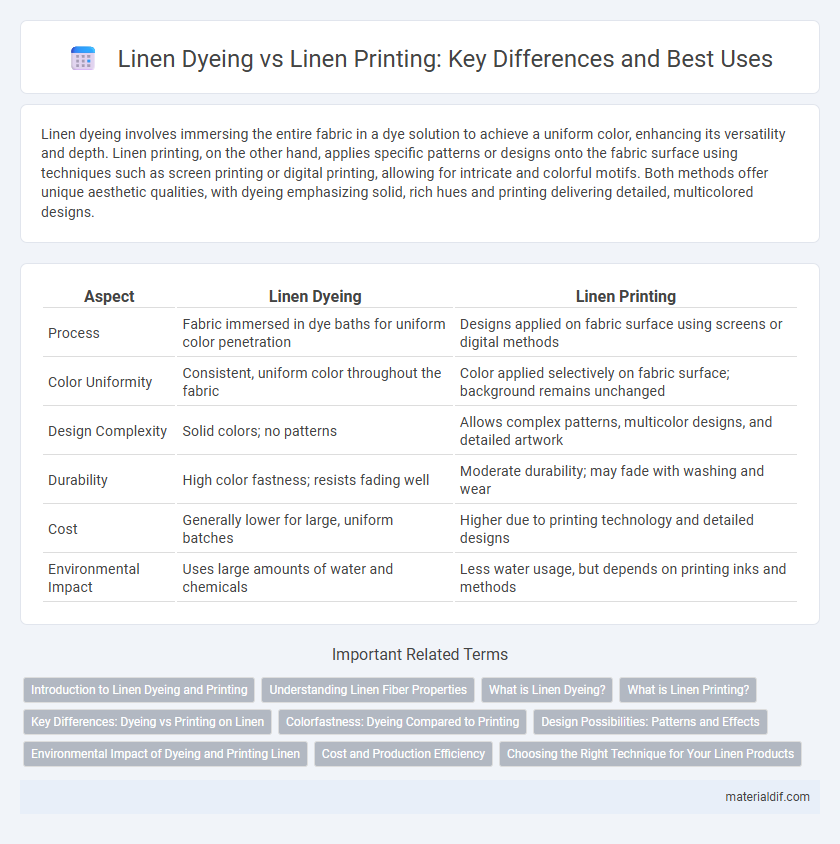

Linen dyeing involves immersing the entire fabric in a dye solution to achieve a uniform color, enhancing its versatility and depth. Linen printing, on the other hand, applies specific patterns or designs onto the fabric surface using techniques such as screen printing or digital printing, allowing for intricate and colorful motifs. Both methods offer unique aesthetic qualities, with dyeing emphasizing solid, rich hues and printing delivering detailed, multicolored designs.

Table of Comparison

| Aspect | Linen Dyeing | Linen Printing |

|---|---|---|

| Process | Fabric immersed in dye baths for uniform color penetration | Designs applied on fabric surface using screens or digital methods |

| Color Uniformity | Consistent, uniform color throughout the fabric | Color applied selectively on fabric surface; background remains unchanged |

| Design Complexity | Solid colors; no patterns | Allows complex patterns, multicolor designs, and detailed artwork |

| Durability | High color fastness; resists fading well | Moderate durability; may fade with washing and wear |

| Cost | Generally lower for large, uniform batches | Higher due to printing technology and detailed designs |

| Environmental Impact | Uses large amounts of water and chemicals | Less water usage, but depends on printing inks and methods |

Introduction to Linen Dyeing and Printing

Linen dyeing involves immersing the fabric in liquid dyes, allowing deep penetration and uniform coloration ideal for achieving solid, rich colors. Linen printing, by contrast, applies pigments or dyes in specific patterns on the fabric surface using techniques such as screen printing or digital printing, resulting in detailed and decorative designs. Both methods enhance linen's natural texture but differ in color application, durability, and design flexibility.

Understanding Linen Fiber Properties

Linen dyeing deeply penetrates the natural flax fibers, enhancing fabric durability and colorfastness by bonding with its high absorbency and moisture-wicking properties. Linen printing applies pigments or dyes on the surface, allowing for intricate designs but with less color penetration, making it more prone to fading over time. Understanding linen's coarse fiber structure and strong cellulose content is crucial for selecting the appropriate color application method to maintain fabric integrity and vibrancy.

What is Linen Dyeing?

Linen dyeing involves immersing linen fabric in a dye bath, allowing fibers to absorb color uniformly, resulting in consistent and long-lasting hues. This process enhances the fabric's natural texture while maintaining its breathability and durability. Linen dyeing is preferred for solid colors, providing a smooth and even finish without altering the fabric's inherent quality.

What is Linen Printing?

Linen printing involves applying color patterns directly onto linen fabric using techniques such as screen printing, block printing, or digital printing, creating vibrant and detailed designs. This method allows for precise control over color placement and intricacy, unlike linen dyeing, which uniformly colors the entire fabric by immersing it in dye. Linen printing preserves the texture and breathability of the fabric while offering endless design possibilities for fashion and home textiles.

Key Differences: Dyeing vs Printing on Linen

Linen dyeing involves immersing the entire fabric in a dye bath, resulting in uniform, long-lasting color saturation throughout the fibers. Linen printing, by contrast, applies color only to the fabric's surface using techniques like screen printing or digital printing, allowing for intricate patterns and multi-colored designs. Dyeing offers deeper color penetration and durability, whereas printing enables greater design versatility and detailed motifs on linen textiles.

Colorfastness: Dyeing Compared to Printing

Linen dyeing involves immersing the fabric in dye, resulting in fibers absorbing color deeply and producing high colorfastness that resists fading from washing and sunlight. Linen printing applies color pigments or dyes only to the surface, creating vivid designs but with lower colorfastness, making it more prone to wear and color loss over time. For long-lasting vibrancy, dyed linen outperforms printed linen in maintaining color integrity through repeated use and exposure.

Design Possibilities: Patterns and Effects

Linen dyeing offers rich, uniform color absorption that enhances fabric texture and durability, making it ideal for vibrant solid hues and subtle ombre effects. Linen printing enables intricate patterns, precise motifs, and multicolor designs through techniques like screen printing or digital printing, providing exceptional versatility in artistic expression. Both methods expand design possibilities, with dyeing emphasizing depth and uniformity, while printing excels in detailed and complex visual effects on linen textiles.

Environmental Impact of Dyeing and Printing Linen

Linen dyeing typically involves the use of large volumes of water, synthetic dyes, and chemicals, which can lead to significant water pollution and energy consumption. In contrast, linen printing often uses less water and fewer chemicals but may generate waste from inks and solvents, requiring careful management to minimize environmental harm. Both processes impact the environment, yet advances in eco-friendly dyes and printing technologies are reducing pollution and resource use in linen production.

Cost and Production Efficiency

Linen dyeing involves immersing the entire fabric in dye solutions, resulting in uniform coloration that typically incurs higher costs due to extensive water and chemical usage. Linen printing applies designs selectively, reducing dye consumption and enabling faster production cycles, making it more cost-effective for intricate patterns and smaller batches. Production efficiency favors printing for its lower material waste and quicker turnaround, while dyeing suits large-scale runs where solid colors are desired.

Choosing the Right Technique for Your Linen Products

Linen dyeing involves immersing the entire fabric in a color solution, ensuring even and long-lasting color saturation ideal for uniform products such as tablecloths or curtains. Linen printing applies designs or patterns selectively on the fabric surface using techniques like screen printing or digital printing, perfect for customized or decorative textiles such as linen apparel or accents. Selecting between dyeing or printing depends on the desired aesthetic, budget, and production scale, with dyeing favored for solid colors and durability, while printing excels in intricate patterns and limited color runs.

Linen Dyeing vs Linen Printing Infographic

materialdif.com

materialdif.com